30

Adjustment of respective parts

5.Needle location

Straight needle dropping points

[Condition]

<SD>

Pattern selection dial: "6"

<2D>

Pattern selection dial: "4"

<3D>

Pattern selection dial: "3"

Stitch width lever: "0"

[Diagnosis]

1. Rotate the handweel, bring down the needle

lower than the surface of needle plate.

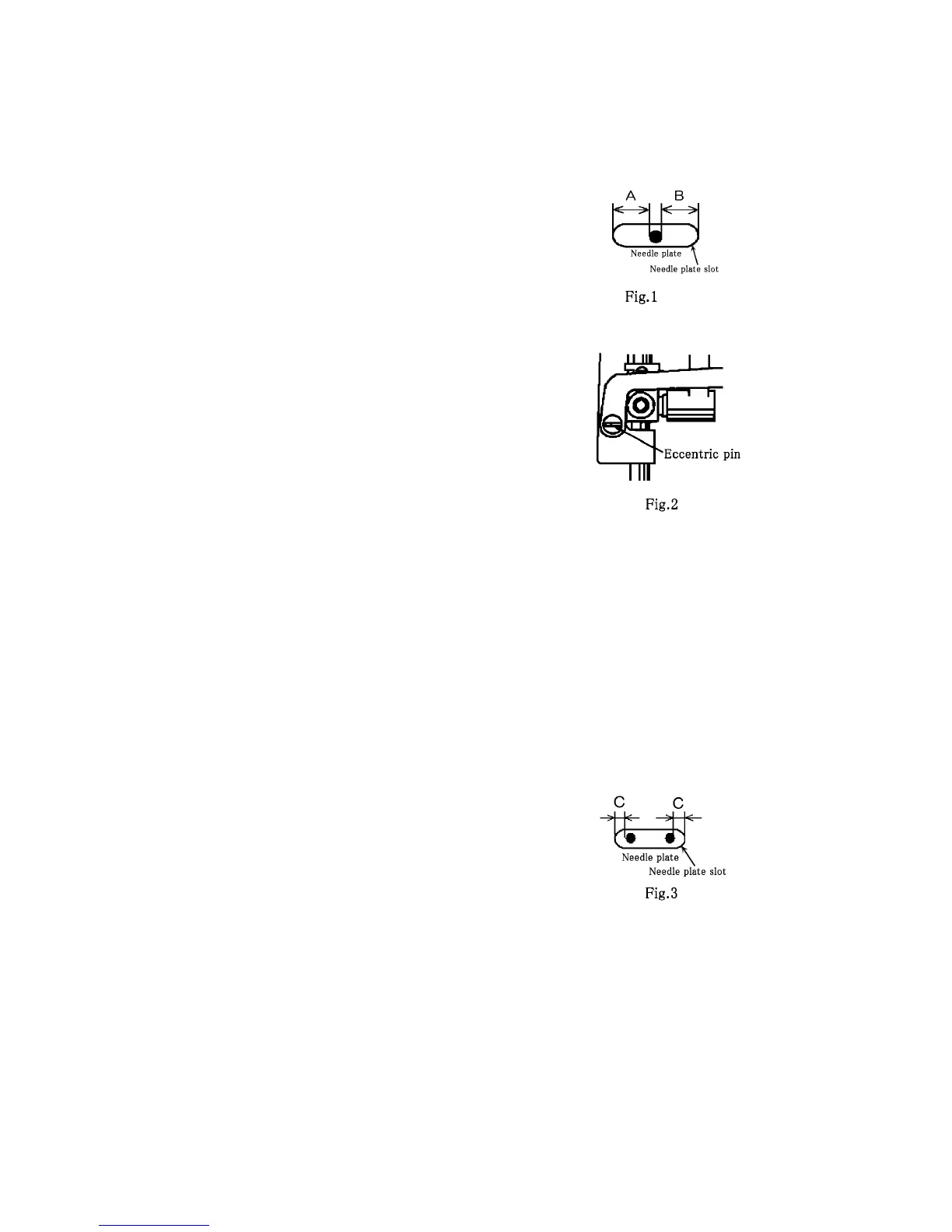

2. Measure the relative position (A, B) between

the needle and the slot.(Fig. 1)

[Standard]

A = B (Fig. 1)

* Make adjustment if the diagnosis result fails to

meet the standard.

[Adjustment]

1. Remove the external panels and others to

see the adjusting section. (See:page.45)

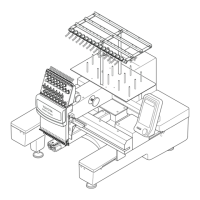

2. Turn the eccentric pin, adjust the needle

location.(Fig. 2)

Right turn moves the needle location to "Left".

Left turn moves the needle location to "Right".

* Repeat the adjustment till the standard is met.

Zigzag needle dropping points

[Condition]

<SD>

Pattern selection dial: "11"

<2D>

Pattern selection dial: "7"

<3D>

Pattern selection dial: "3"

Stitch width lever: "5"

[Diagnosis]

1. Rotate the handweel, bring down the needle

lower than the surface of needle plate.

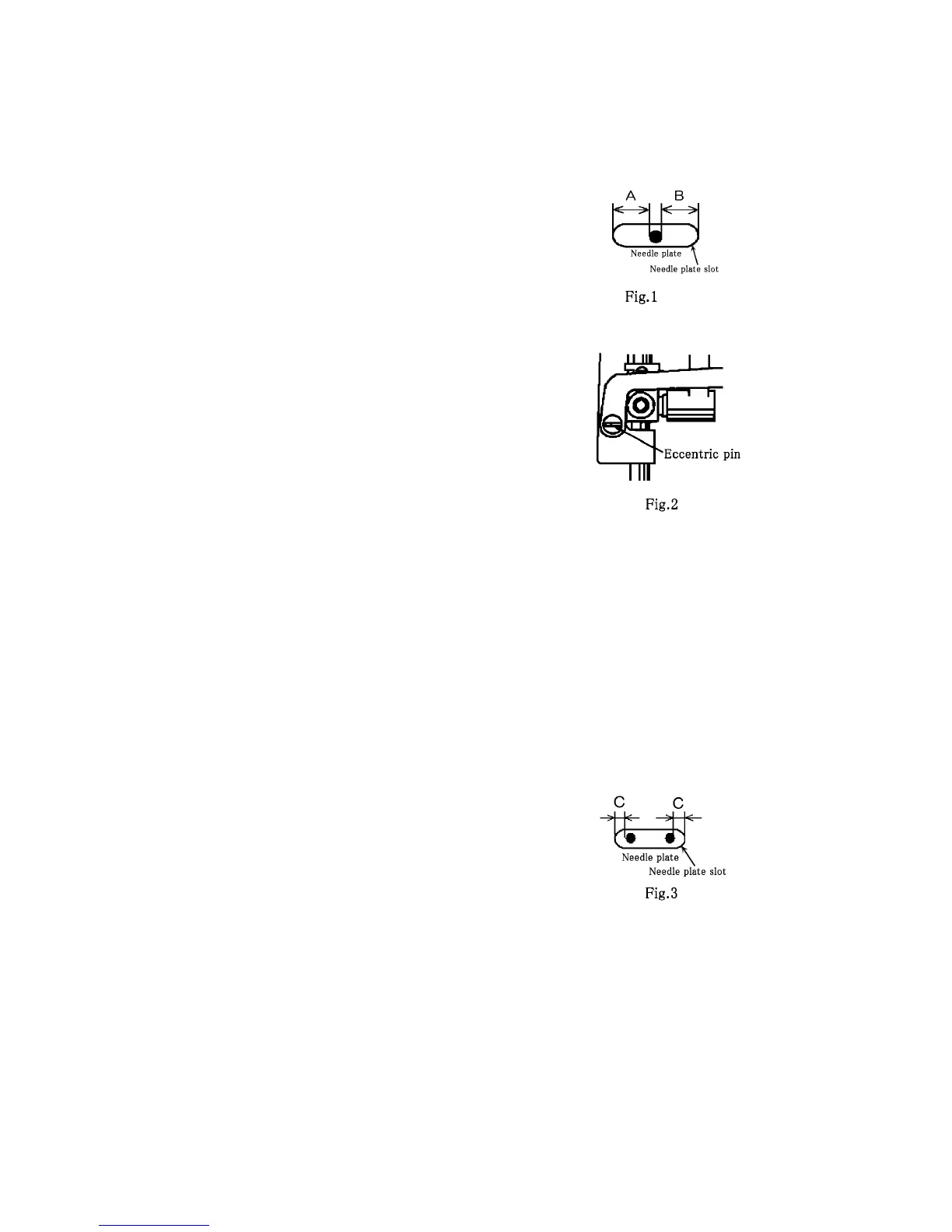

2. Measure the relative position (C) between the

needle and the slot.(Fig. 3)

[Standard]

C = 0.7 ± 0.3 mm (Fig.3)

* Make adjustment if the diagnosis result fails to

meet the standard.

Loading...

Loading...