26

Adjustment of respective parts

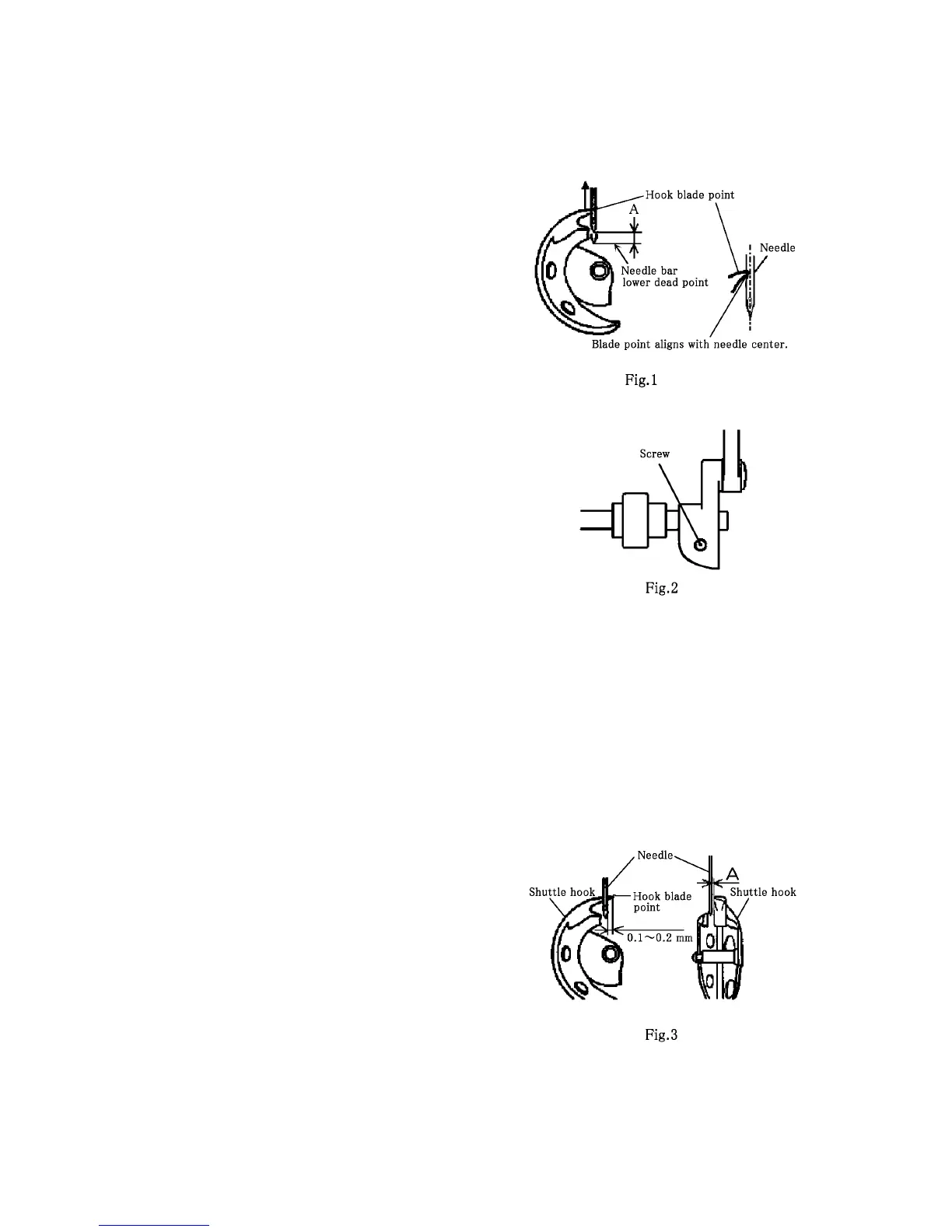

2.Timing between needle and hook

Amount of needle elevation

[Condition]

<SD>

Pattern selection dial: "5"

<2D>

Pattern selection dial: "3"

<3D>

Pattern selection dial: "4"

[Diagnosis]

1. Remove the extension table, and open the

shuttle cover.

2. When the hook blade point is aligned with the

needle center by rotating the handweel, mea-

sure the travel distance (A) of needle bar,

regarding the lower dead point of needle bar

as 0.(Fig. 1)

[Standard]

A = 1.85 ± 0.15 mm (Fig.1)

* Make adjustment if the diagnosis result fails to

meet the standard.

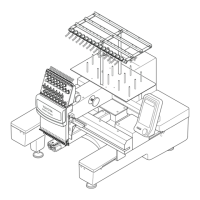

[Adjustment]

1. Remove external panels and others to allow

sewing machine seen from the bottom.

(See:page.45)

2. Loosen the screw at the right side of lower

shaft, adjust the position of hook.(Fig. 2)

3. Tighten the screw.(Fig. 2)

* Repeat the adjustment till the standard is met.

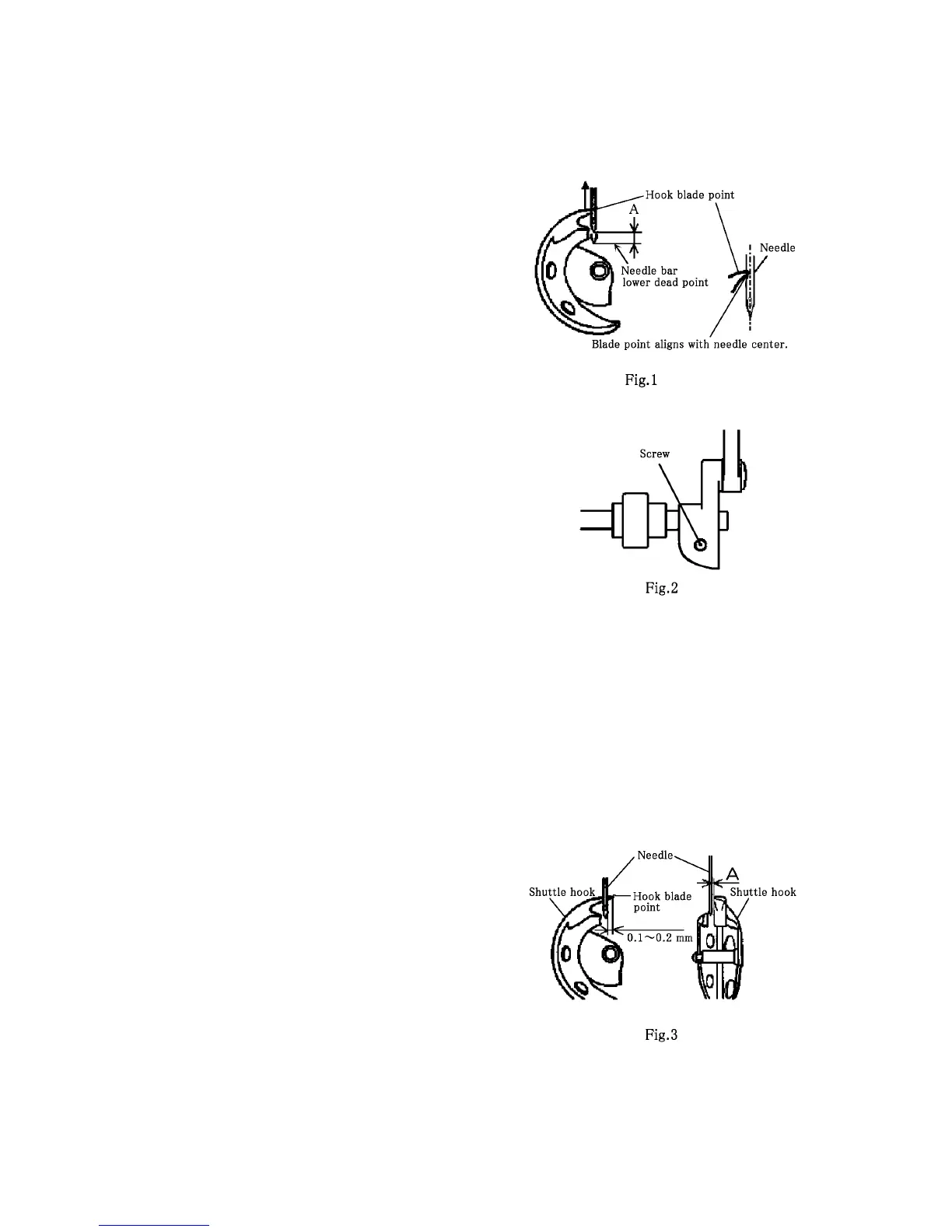

Clearance between needle and hook

[Condition]

<SD>

Pattern selection dial: "6"

<2D>

Pattern selection dial: "4"

<3D>

Pattern selection dial: "3"

Stitch width lever: "0"

[Diagnosis]

1. Turn the handweel beyond the lower dead

point of needle bar. When the hook blade

point has protruded by 0.1 to 0.2 mm from the

side face of needle, measure the clearance

(A) between the needle and the hook.(Fig. 3)

Loading...

Loading...