BASIC INSPECTION

When the normal code is displayed in the diagnostic code check, troubleshooting should be performed in the

order for all possible circuits to be considered as the causes of the problems.

In many cases, by carrying out the basic engine check shown in the following flow chart, the location causing

the problem can be found quickly and efficiently. Therefore, use of this check is essential in engine troubleshoot-

ing.

Is Battery voltage 11 V or more when engine is stopped?

Change or replace battery.

Does engine crank?

Go to Matrix Chart of Problem Symptoms

(See page TR–21).

Does engine start?

Go to step [ 8 ].

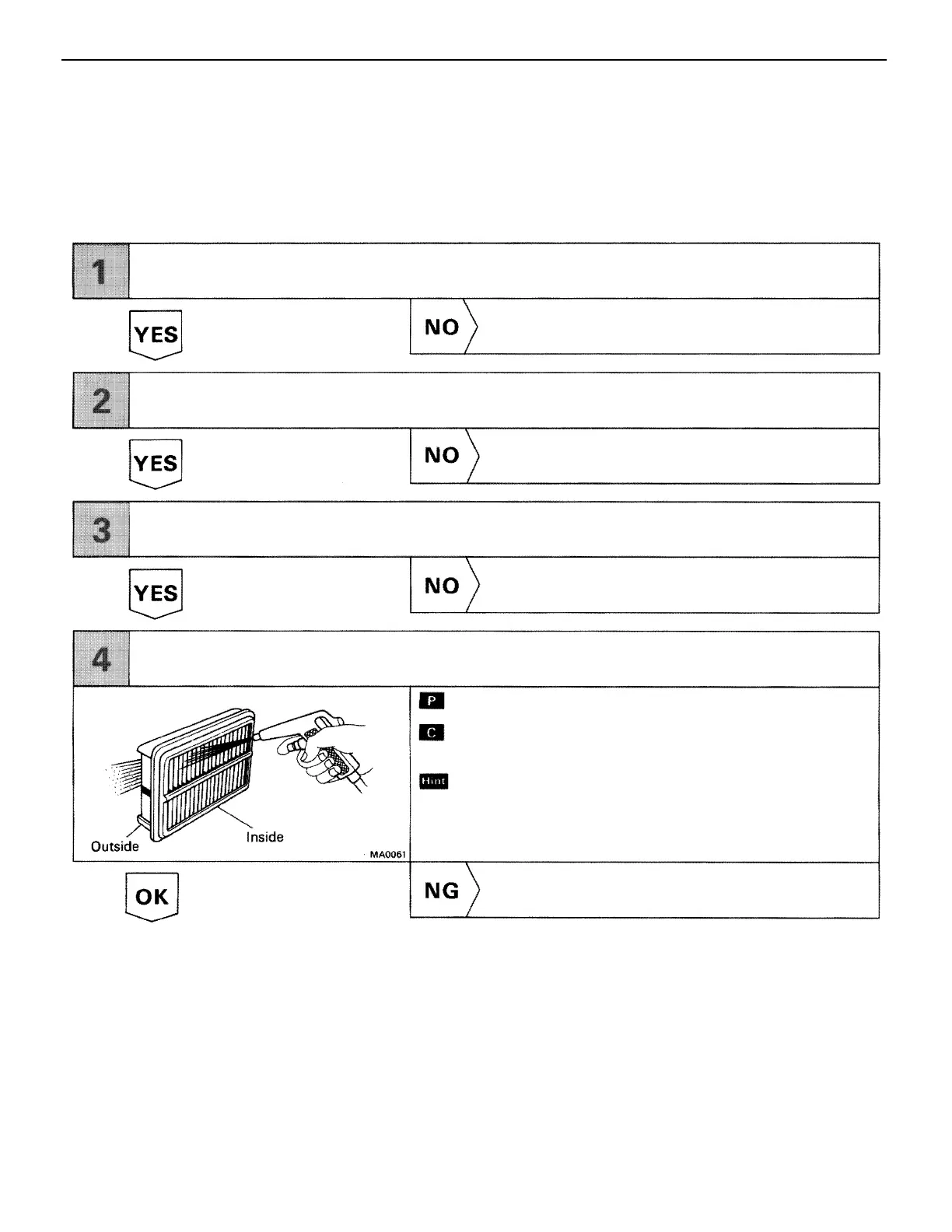

Check air filter.

Replace air cleaner element.

Remove air filter.

Visually check if the air cleaner element is not exces-

sively damaged or oily.

If necessary, clean the element with compressed air.

First blow from inside thoroughly, then blow off out-

side of element.

–ENGINE TROUBLESHOOTING Basic Inspection

TR–19

Loading...

Loading...