©1999 Trace Engineering

Battery Wiring

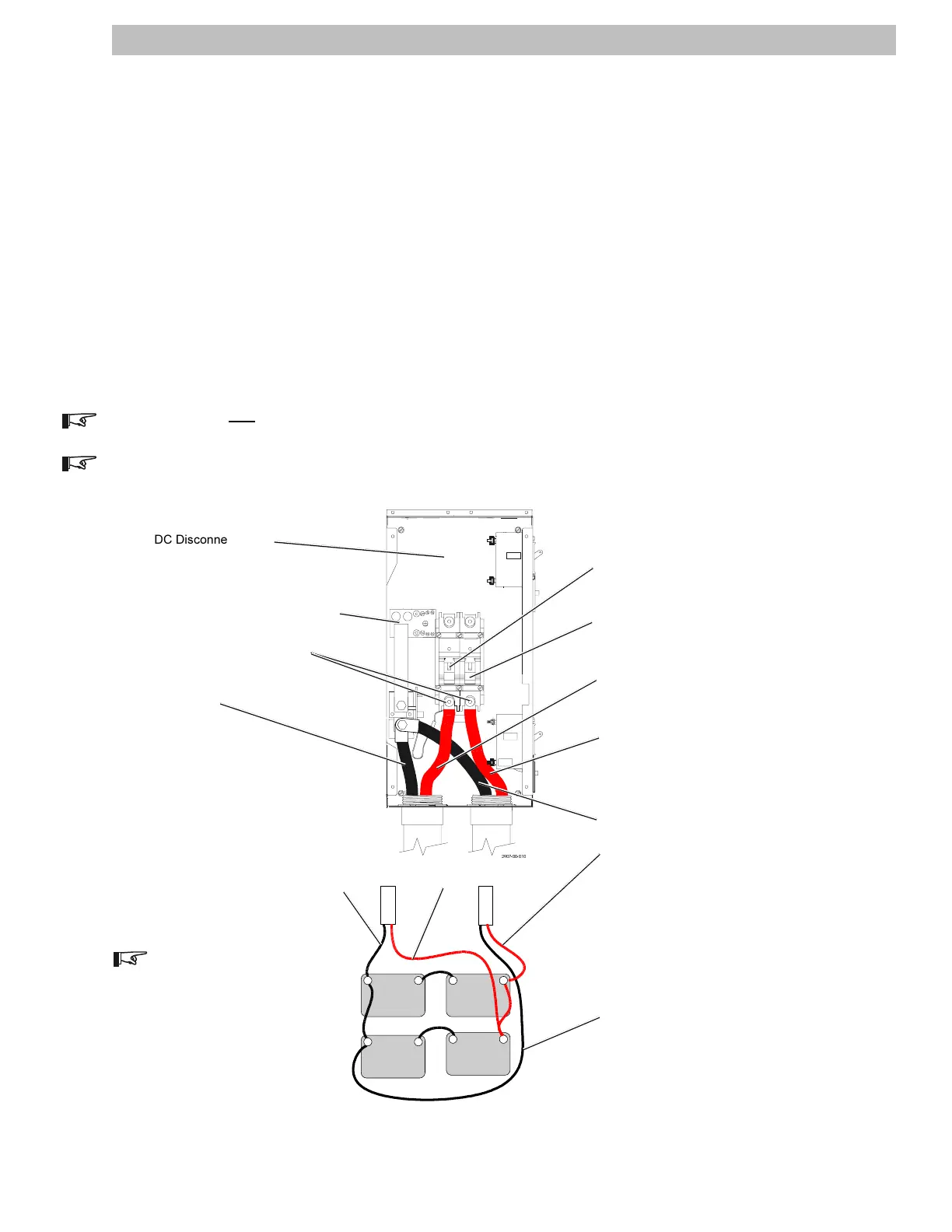

Route the battery cables through the conduit to the DC Disconnect Box. Use a minimum of #4/0 AWG

wire for a 250 amp battery disconnect breaker (or #2/0 AWG for a 175 amp battery disconnect breaker).

Smaller diameter wire results in poor inverter performance and the risk of fire due to the wires overheating.

Connect the Negative wires to the negative grounding bond block and tighten connections.

Connect a Positive wire to one of the lower terminals on the Battery Disconnect breaker.

Connect the other Positive wire to the lower terminal on the second Battery Disconnect breaker.

Torque Battery breaker connections to 275 in-lb (23 ft-lb), (31 N-m). Refer to battery manufacturers

specifications for battery terminal torque specifications.

After torquing, coat the battery connections with petroleum jelly or other anticorrosion grease designed

for battery terminals. Do not put any anticorrosion grease between the terminals and the battery cable.

NOTE: Use only

one battery bank for both inverters. Refer to Figure 12 for an example of a battery hookup.

NOTE: Refer to the inverters Operators manual for more detailed examples of battery hookups (i.e., 12 V,

24 V and 48 V).

Figure 12

Battery Wiring (24 v dc System)

2.0 INSTALLATION

11

DISCONNECT

BATTERY

OFF

ON

OFF

ON

ARRAY

SOLAR

SOLAR

ARRAY

ARRAY

SOLAR

DC Disconnect Box

Battery Disconnect 1 Breaker

(DR system shown)

(Disconnect 2 on SW Systems)

Battery Disconnect 2 Breaker

(DR system shown)

(Disconnect 1 on SW Systems)

Negative 1

Negative Grounding Bond Block

(On opposite side on SW

installations)

Positive 1

Positive 2

Negative 2

–

– + – +

+–

+

CONDUIT FOR

INVERTER 2

CONDUIT FOR

INVERTER 1

2903-00-021

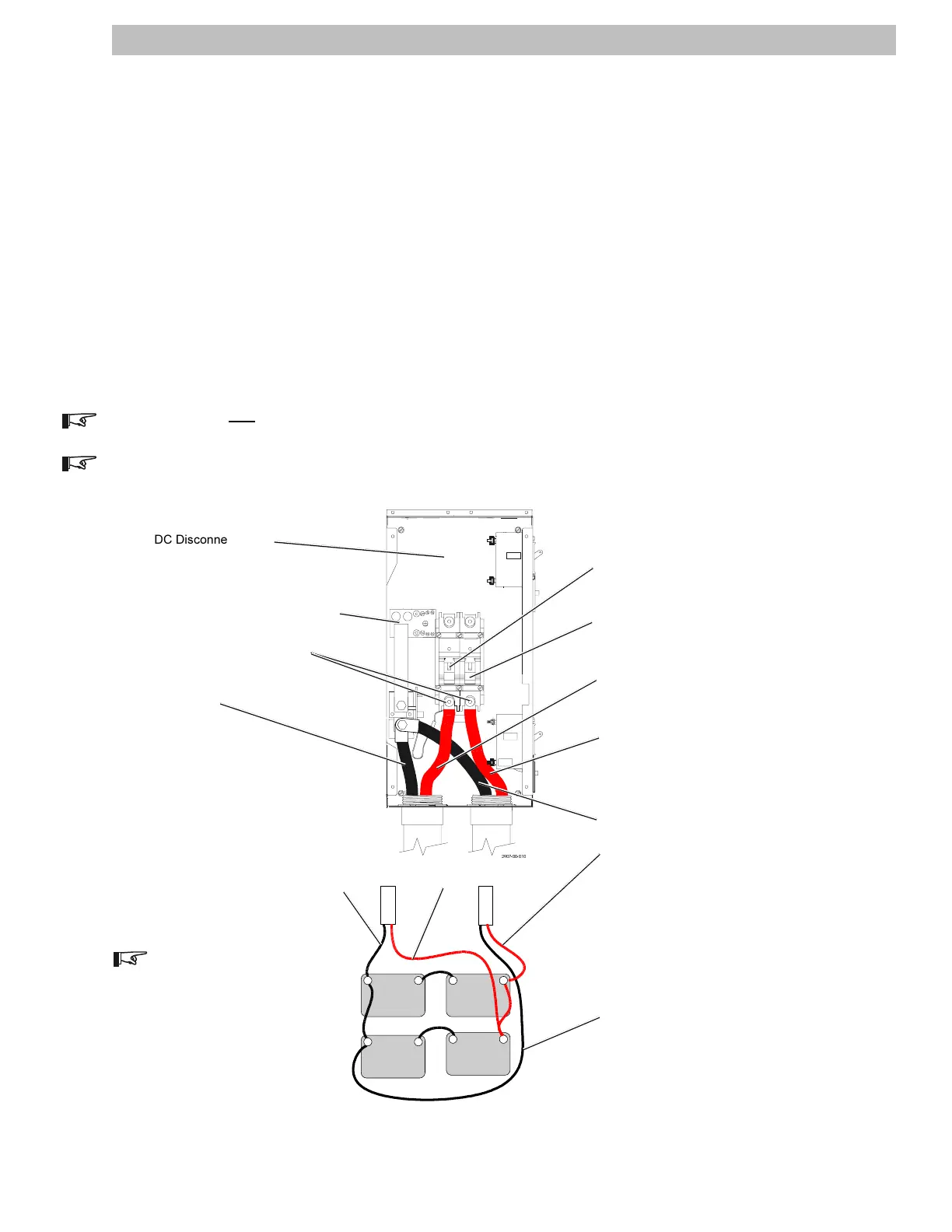

12 Volt

Battery

12 Volt

Battery

12 Volt

Battery

12 Volt

Battery

Positive 1

Positive 2

Negative 1

Negative 2

NOTE: Connect each inverter at

opposite ends of the battery

bank. This balances the current

flowing through the entire bank

and provides an equal charge/

discharge through all of the

batteries.

Torque to 275 in-lb (23 ft-lb)

Loading...

Loading...