36

MAINTENANCE

Wheel Installation

NOTICE: To decrease the risk of component damage, do not tighten the lug nuts

to more than the specified torque.

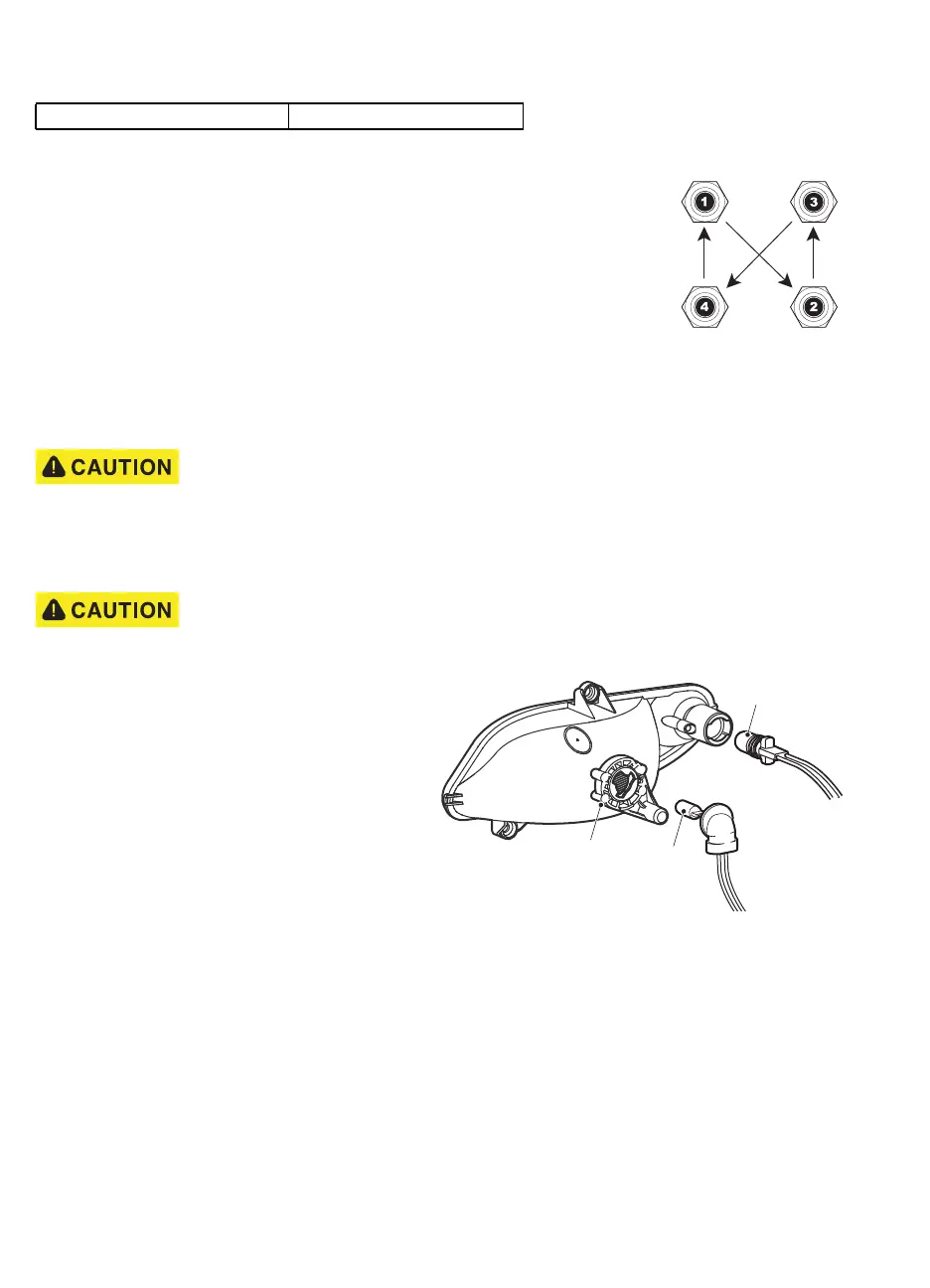

Always install lug nuts using a cross sequence pattern to ensure the

even seating of the wheel against the hub.

1. Install the wheel on the hub with lug nuts. Make sure the valve stem is to the out-

side.

2. Finger tighten the lug nuts.

3. Using the cross tightening pattern shown to the right, tighten the lug nuts to 65 - 85

ft.lbs. (88 - 115 Nm). Tighten in increments of 20 ft. lbs. (27 Nm).

LIGHTS

• Clean the lights frequently to maximize visibility.

• Replace burned out bulbs promptly.

Do not operate this vehicle at nightorinlow lightifanybulbsareburned out. Poor light-

ing reduces visibility that couldcause an accident resulting in severe injury or death.

NOTICE: Replacement bulbs are available from a local Distributor, an authorized Branch or the Service Parts

Department.

Headlight

Toprevent bulb from inadvertantlydisconnecting and possiblymelting or igniting plas-

ticcomponents, the locking ring MUSTbereinstalled after installation of replacement

bulb.

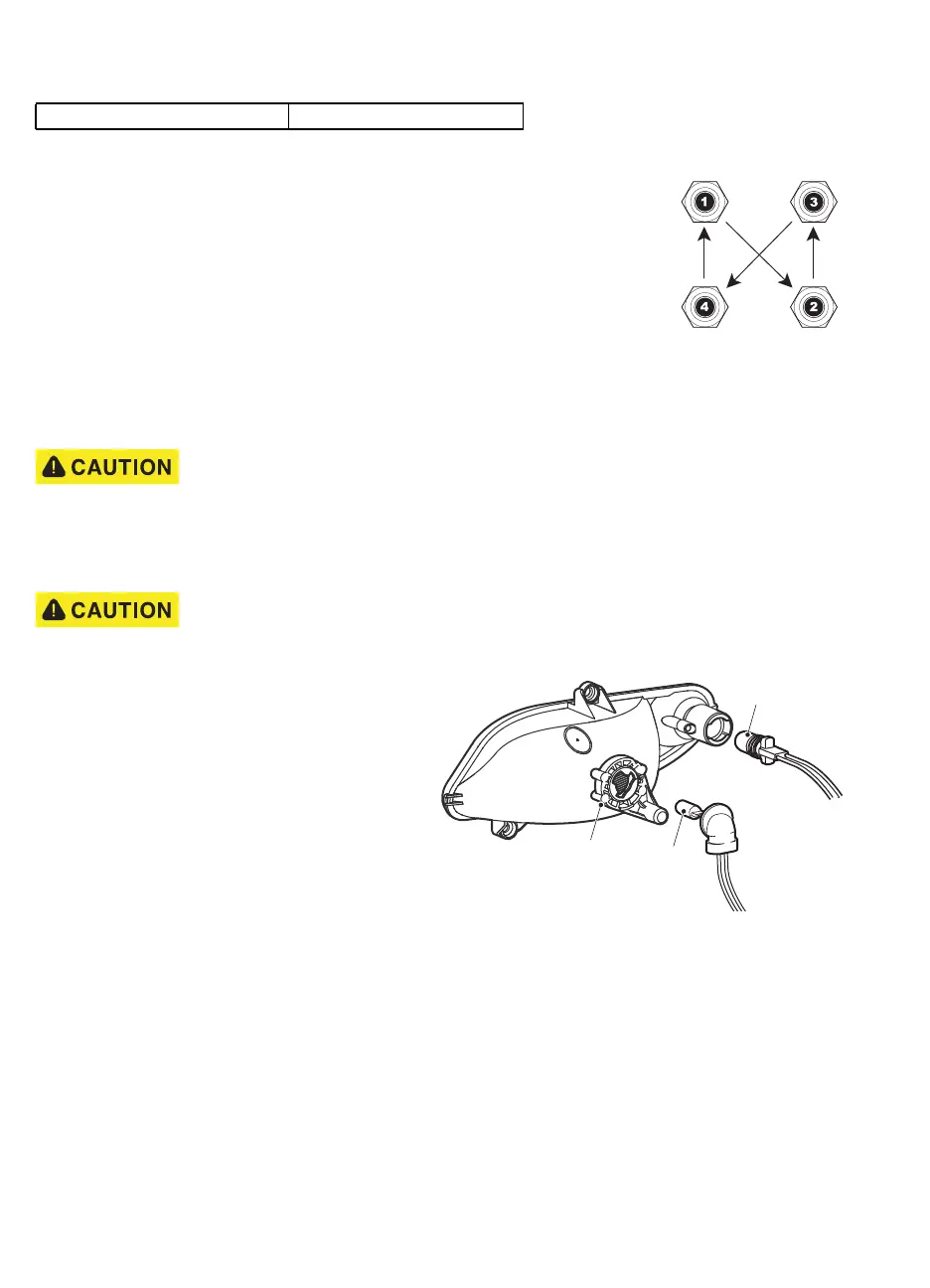

Pull the locking ring straight off the back of the light

housing and allow it to slide down the harness and

out of the way.

Rotate bulb socket a quarter turn counterclockwise to

unlock. Pull out bulb and socket. Insert new bulb and

rotate socket a quarter turn clockwise to secure.

Slide locking ring over new bulb socket and onto back

of light housing.

Lug Nut Torque 65 - 85 ft.lbs. (88 - 115 Nm)

Lug Nut Tightening Pattern

Turn Signal

Bulb

Headlight

Bulb

Locking

Ring

Loading...

Loading...