40

MAINTENANCE

STARTER/GENERATOR BELT

Check the starter/generator belt at the initial service and then intervals indicated in the SCHEDULED MAINTENANCE

CHART on page 30.

Never allow the tension to exceed 160 lbs (73 kg) while installing the belt.

At the time of installation, the belt must not be rolled overthe installed edgesofthe starter/generator or drive

clutch pulleys. Excessive stretch in the belt can causecord failure.

A

NOTICE: A loose belt can cause audible vibration and squeal.

1. New belt:

a. Tighten a new starter/generator belt to 25 - 30 lbs. (110 -

130 N) tension when a gauge is applied half way between

the two pulleys.

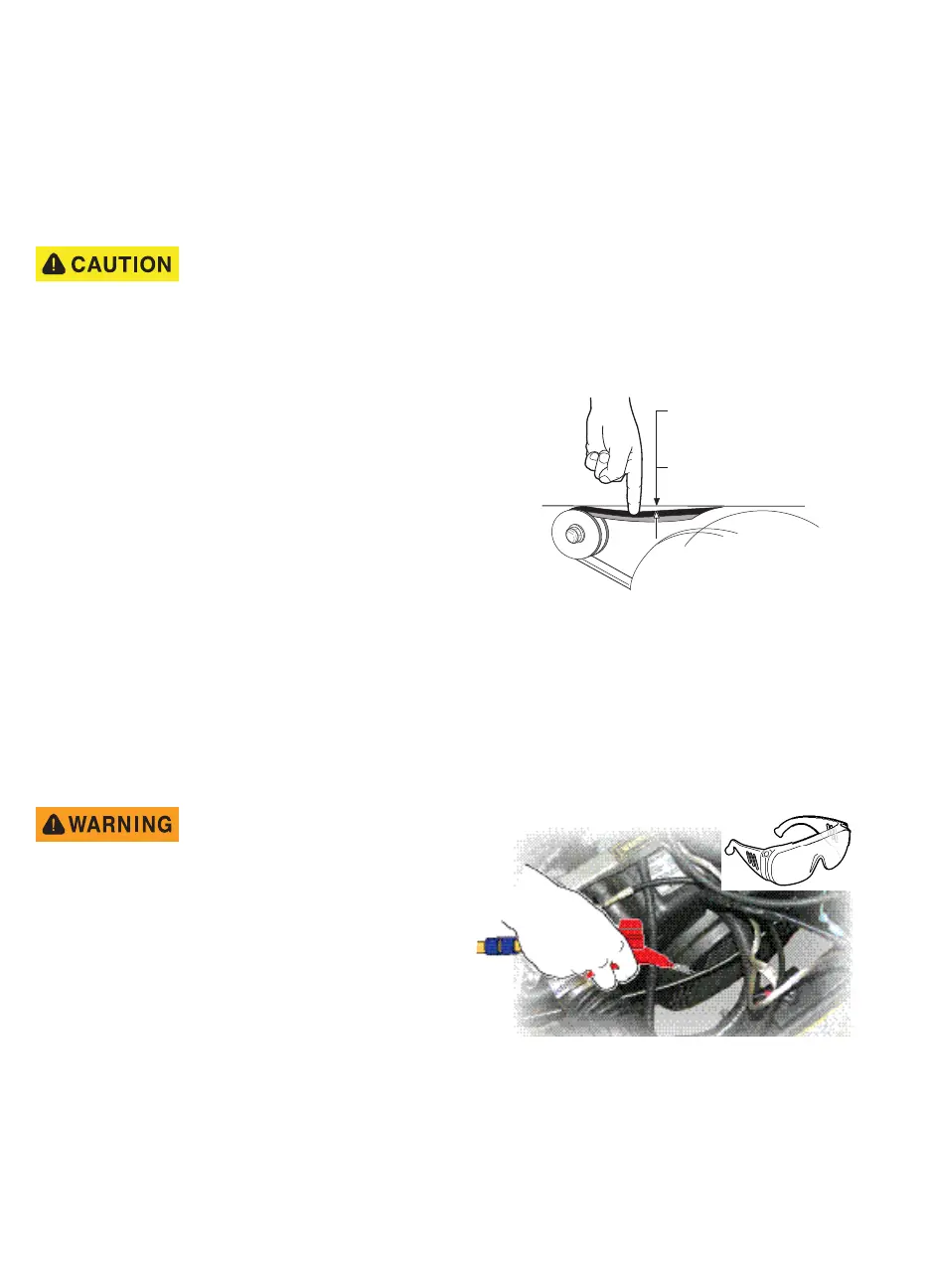

b. A new belt may be checked manually. A maximum deflection

of 3/8” (10 mm) is acceptable.

2. Existing belt:

a. Tighten an existing belt to 17 - 18 lbs. (75 - 80 N) tension

using the same technique.

b. Inspect for cracks or wear. A maximum deflection of 1/2” (13

mm) is acceptable.

Adjusting the Belt

1. Loosen the starter/generator pivot bolt.

2. While holding the lower adjusting nut with a wrench, loosen the upper jam nut with another wrench. Move the

lower nut up or down the adjustment bolt until the correct belt tension is achieved.

3. Hold the lower nut in place and tighten the upper jam nut against it.

4. Tighten the starter/generator pivot bolt.

AIR INTAKE AND COOLING FINS

Keepthe enginecoolingcompo-

nents clean to reduce the risk of

overheating and the possible igni-

tion of accumulated debris.

Dirt and debris can clog the engine air cooling system. Allow

the engine to cool and use the following guidelines after

every off-road use:

• Check for a build up of dirt and debris in the air intake and

cooling fins.

• Clean the areas shown to prevent engine damage.

• Make sure the linkages, springs and controls are clean.

• Make sure the area around the muffler is free of any com-

bustible material.

Regular maintenance of the cooling system is required to ensure an adequate supply of air to the cooling fins. Com-

pressed air can be used for routine cooling system maintenance.

Clean the cooling system at the intervals indicated in the SCHEDULED MAINTENANCE CHART on page 30.

Tools

• Belt Tension Gauge • Ratchet

• Wrench, 3/4” • Socket, 3/4”

• Wrench, 9/16”

3/8" (1 cm) Maximum

Deflection (New Belt)

1/2" (1.3 cm) Maximum

Deflection (Existing Belt)

Loading...

Loading...