BM-20 PLUS Operator’s Manual 9

After setting the bevel angle, adjust the bevel width using the depth knob. The

widt

h pitch provides only a rough value as the bevel width varies with the angle.

The maximum bevel width

(b = 21 mm, 13/16’’) is obtained for 45°. The demanded

bevel width for the required angle must be determined experimentally by gradually

increasing the penetration of the milling cutters into the workpiece.

3.2. Operating

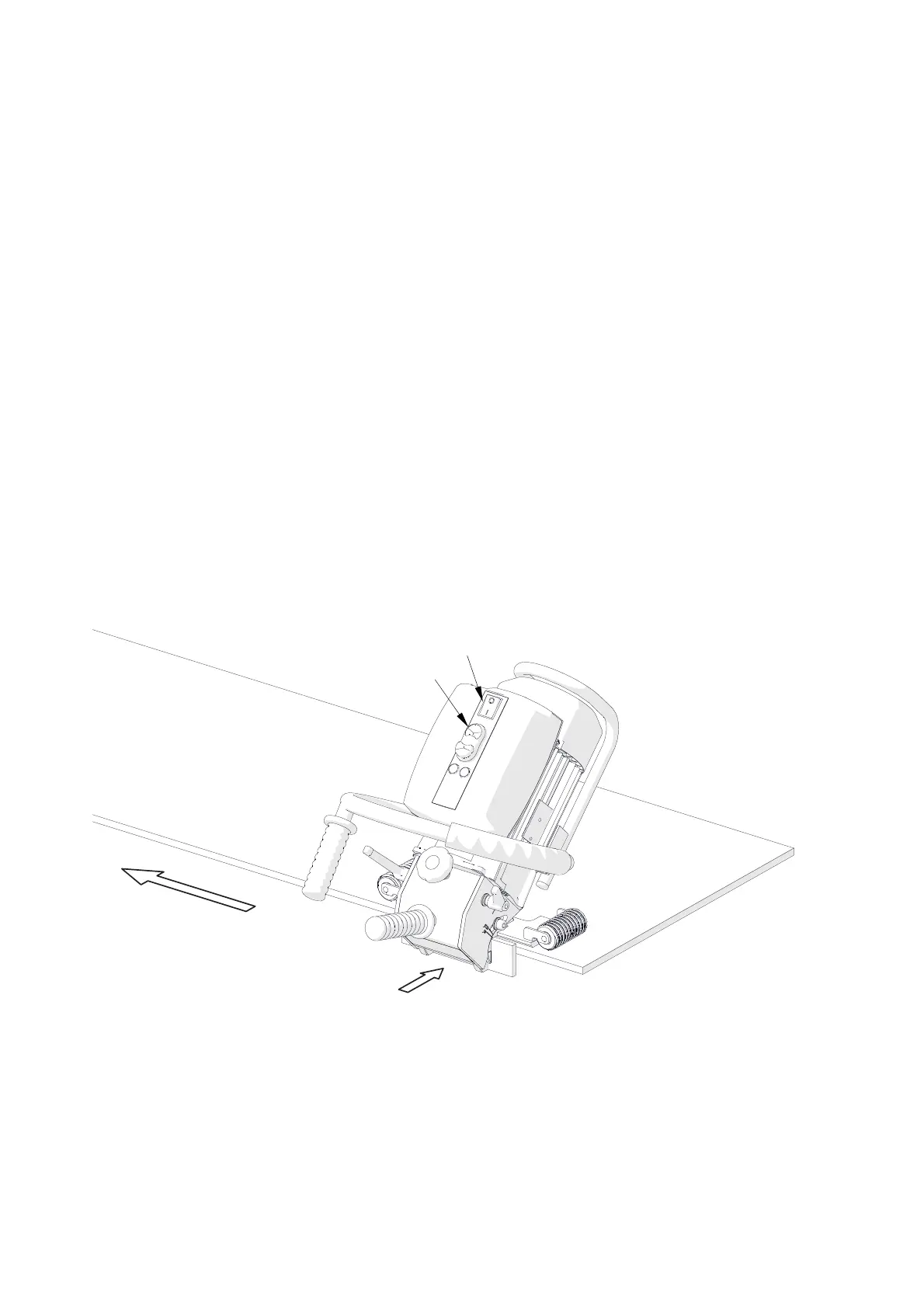

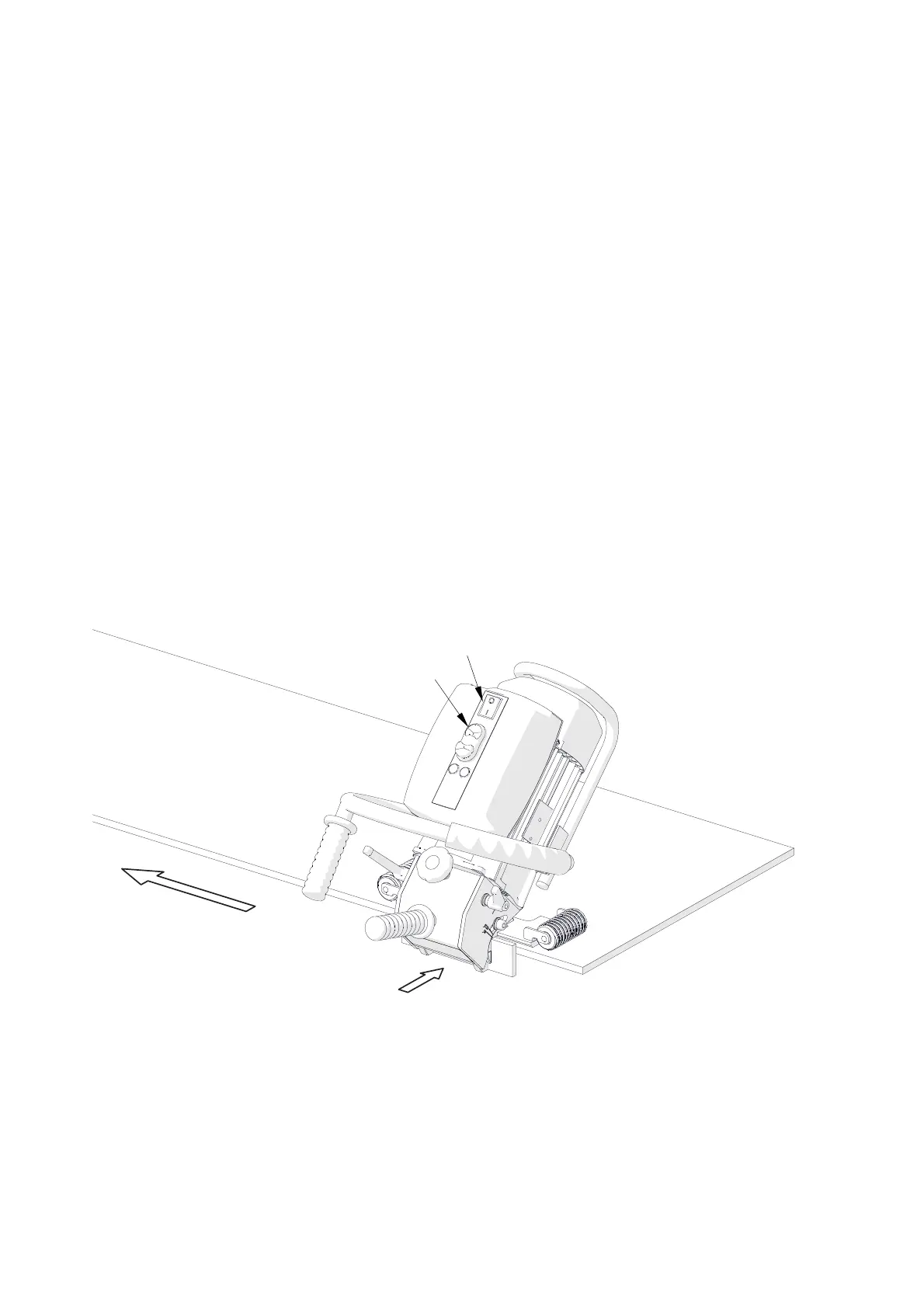

After setting the bevel angle and width, connect the machine to a properly grounded

power outlet. Then, place the machine vertically on the right side of the workpiece in

such a way to rest the rollers on the plate (Fig. 5) and maintain a gap between the

milling cutters and the plate. Next, power on the machine by toggling the power switch

to position ‘I’ and start the motor using the green START button. Slide the machine

towards the plate face and bevel by sliding the machine to the left, constantly pressing

the machine against the workpiece.

Bevelling is performed according to the counter-rotation. The rotation direction of

the milling cutters is marked on the motor disk under the milling cutters cover.

Fig. 5. Machine properly positioned on the workpiece

The feed rate will depend on the profile and composition of the workpiece.

Most steels capable of being welded can be bevelled in one pass. However,

bevels wider than 12 mm (1/2’’) should be accomplished in at least two or three passes

as this will require less effort and the process will take less total time than for bevelling

in a single pass.

Feed direction

Power switch

START

Slide towards after starting the motor

Loading...

Loading...