For refrigeration pipe sizing, installation, and charging, please reference the outdoor unit

installation section or separate manual if not included.

Refrigerant Piping Tips

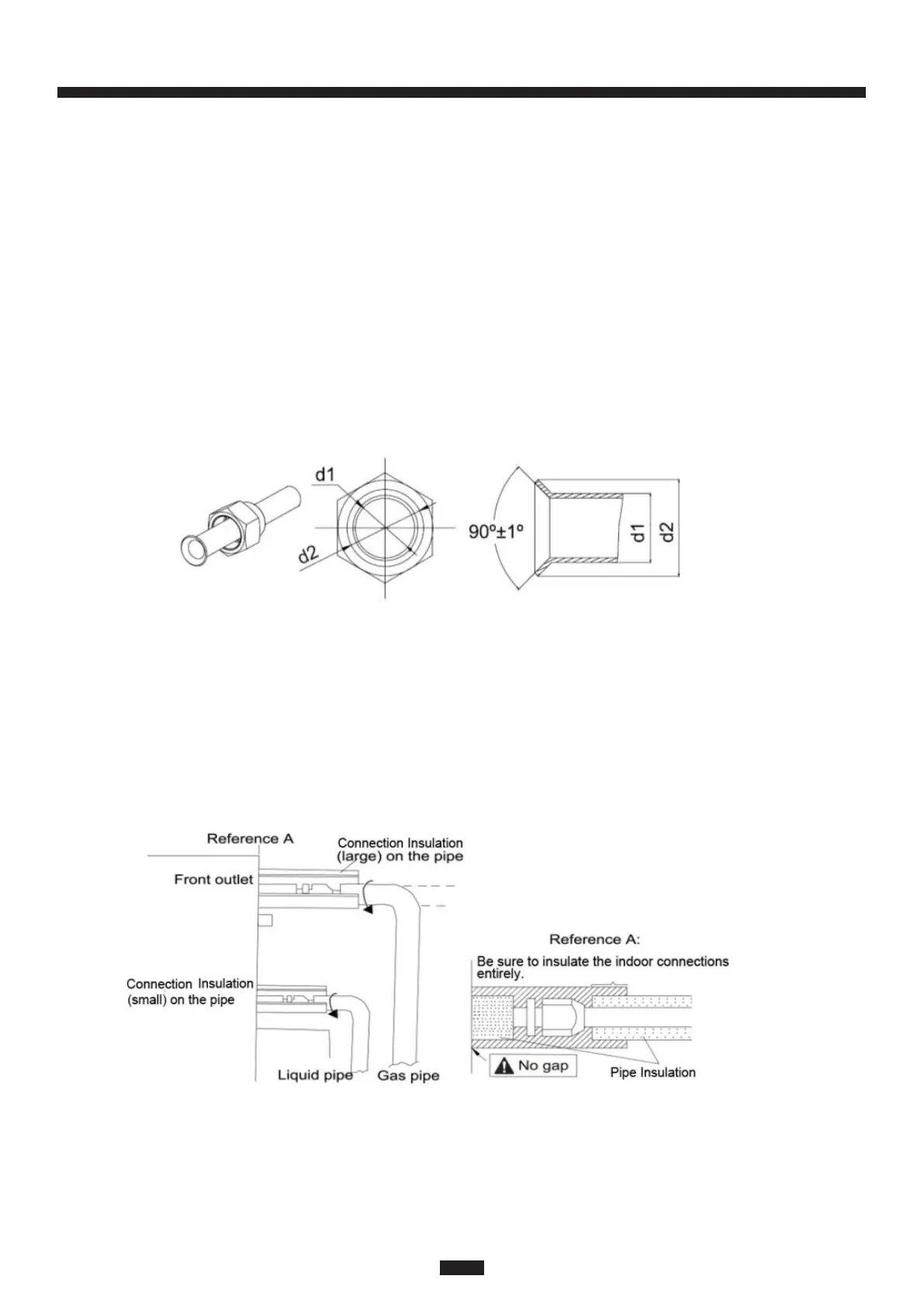

Flaring Process

1. Hold the pipe downward to prevent cuttings from entering the pipe.

2. Using an appropriate tube cutter and deburring tool, cut and deburr the refrigerant pipe.

3. Remove the flare nuts at the stop valve of the outdoor unit and inside the accessory bag of

the indoor unit, put them onto the refrigerant pipe as shown below then flare the refrigerant

pipe with a flaring tool.

4. When flaring copper tubing, only use flaring tools that utilize an orbiting mandrel and

clutched handle. These are typically referenced as R410A flaring tools. By using this type of

flaring tool, the copper tubing is rolled while being pressed, thereby reducing the probability

of copper flare cracking.

5. Check if the flare part is spread evenly and there are no cracks.

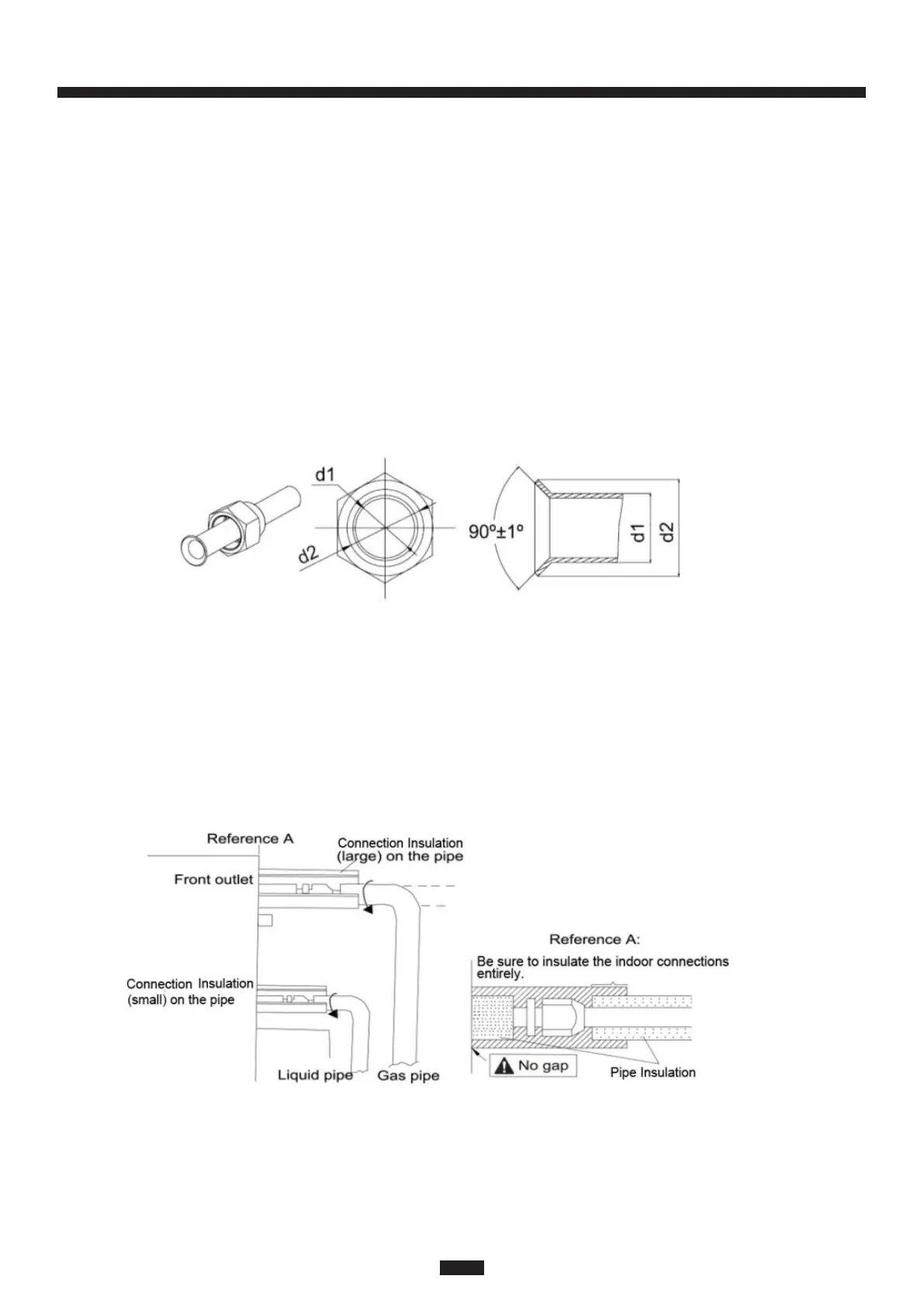

Insulating the Refrigerant Piping and Connections

1. The refrigerant pipes should be insulated and wrapped with appropriate insulating

material and wrapping tape. This will prevent condensation, water leakage and

damage to the insulating material.

2. The connections at the indoor unit should be wrapped with insulating material. No

gap is allowed on the joint of the indoor unit, as shown below.

17

23 Series High Wall Unit

Loading...

Loading...