84

SCXF-SVX01T-EN

sound and gas-tight connection.

9. Visually inspect the connection after brazing to locate

any pinholes or crevices in the joint. Use a mirror if joint

locations are difficult to see.

System Evacuation Procedures

• Each refrigeration circuit must be evacuated before the

unit can be charged and started.

• Use a rotary type vacuum pump capable of pulling a

vacuum of 100 microns or less.

• Verify that the unit disconnect switch and the system

control circuit switches are “OFF”.

• Oil in the vacuum pump should be changed each time

the pump is used with high quality vacuum pump oil.

Before using any oil, check the oil container for

discoloration, which usually indicates moisture in the oil

and/or water droplets. Moisture in the oil adds to what

the pump has to remove from the system, making the

pump inefficient.

• When connecting vacuum pump to refrigeration

system, it is important to manifold vacuum pump to

both high and low side of system (liquid line access

valve and suction line access valve). Follow pump

manufacturer’s directions for proper methods of using

vacuum pump.

• Lines used to connect the pump to the system should

be copper and of the largest diameter that can

practically be used. Using larger line sizes with

minimum flow resistance can significantly reduce

evacuation time.

• Rubber or synthetic hoses are not recommended for

system evacuation. They have moisture absorbing

characteristics that result in excessive rates of

evaporation, causing pressure rise during standing

vacuum test. This makes it impossible to determine if

system has a leak, excessive residual moisture, or

continual or high rate of pressure increase due to

hoses.

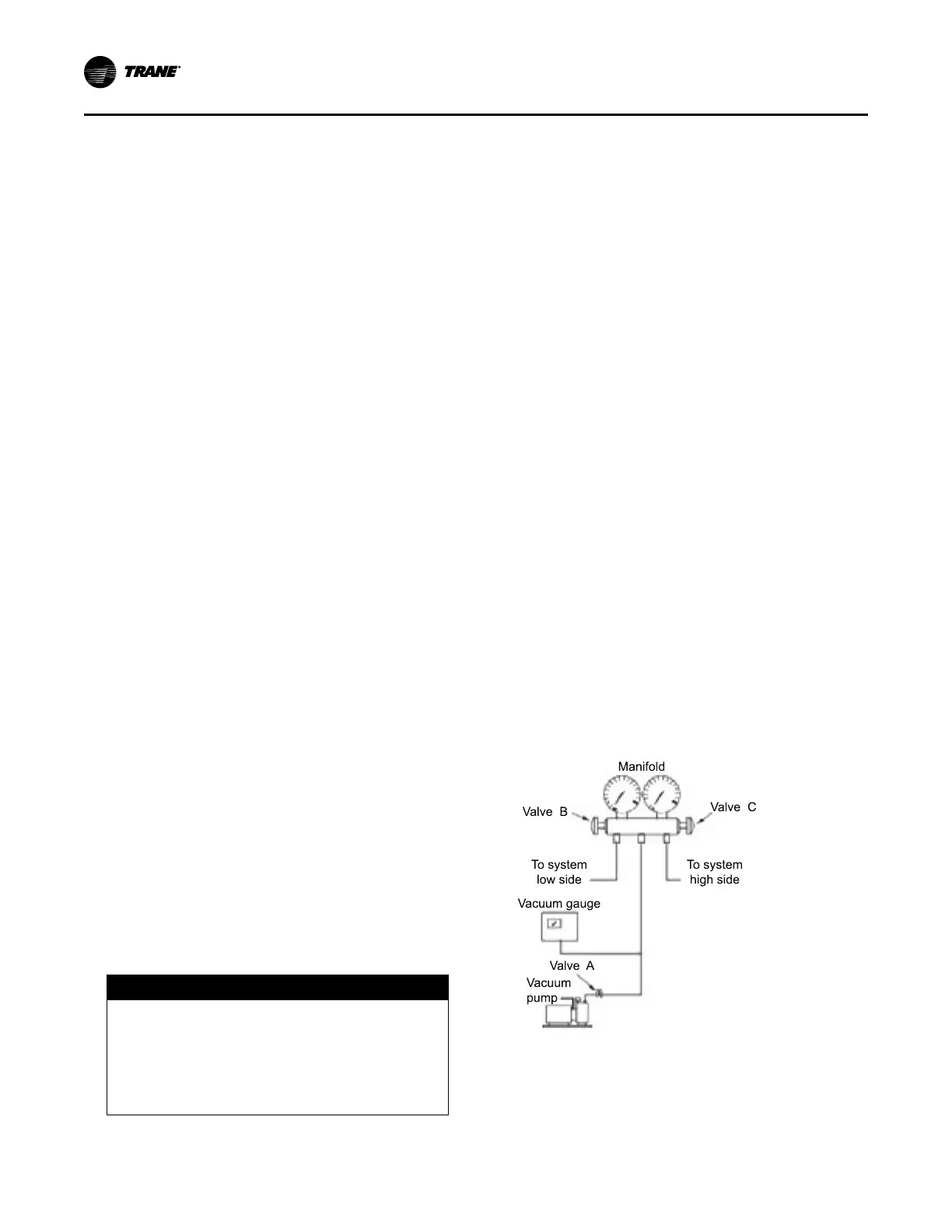

• Install an electronic micron vacuum gauge in the

common line ahead of the vacuum pump shutoff valve,

as shown in Figure 45, p. 84. Close Valves B and C,

and open Valve A.

• Start vacuum pump. After several minutes the gauge

reading will indicate the maximum vacuum the pump is

capable of pulling. Rotary pumps should produce

vacuums of 100 microns or less.

NOTICE

Motor Winding Damage!

Failure to follow instructions below could result in

compressor motor winding damage.

Do not use a megohm meter or apply voltage

greater than 50 VDC to a compressor motor

winding while it is under a deep vacuum.

• Open Valves B and C. Evacuate system to a pressure

of 300 microns or less. As vacuum is being pulled on

system, it may appear that no further vacuum is being

obtained, yet pressure is high. It is recommended

during evacuation process to “break” vacuum to

facilitate evacuation.

• To break the vacuum, shut valves A, B, and C and

connect a refrigerant cylinder to charging port on

manifold. Purge air from hose. Raise standing vacuum

pressure in system to “zero” (0 psig) gauge pressure.

Repeat process two or three times during evacuation.

Note: It is unlawful to release refrigerant into the

atmosphere. When service procedures require

working with refrigerants, the service technician

must comply with all Federal, State, and local

laws.

Standing Vacuum Test

Once 300 microns or less is obtained, close valve A and

leave valves B and C open to allow the vacuum gauge to

read the actual system pressure. Let system equalize for

approximately 15 minutes. This is referred to as a “standing

vacuum test” where time versus pressure rise. Maximum

allowable rise over a 15 minute period is 200 microns. If

pressure rise is greater than 200 microns but levels off to a

constant value, excessive moisture is present. If pressure

steadily continues to rise, a leak is indicated. Figure 46, p.

85 illustrates three possible results of “standing vacuum

test”.

If a leak is encountered, repair the system and repeat the

evacuation process until the recommended vacuum is

obtained. Once the system has been evacuated, break the

vacuum with refrigerant and complete the remaining Pre-

Start procedures before starting the unit.

Figure 45. Typical vacuum pump hookup

Maintenance

Loading...

Loading...