CVHE-SVN04M-EN

25

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

PPrrooppeerrllyy ssuuppppoorrtt tthhee ccoommpprreessssoorr ccaassttiinngg ffoooott ttoo

aavvooiidd pprreevveenntt bbrreeaakkaaggee aanndd eeqquuiippmmeenntt ddaammaaggee..

NNoottee:: Plan ahead where the compressor will be

secured. Build a suitable plant form to support

the assembly before the lift. Gently set

compressor onto prefabricated pre-formatted

support. Use care not to damage the cast

compressor foot (see foot in Figure 8, p. 22).

Similarly, avoid damage to the discharge volute

flange (see discharge flange in Figure 9, p. 22).

8. Remove the compressor/motor assembly. Remove

the locating dowel pins from the compressor foot

and discharge flange connections as shown in

Figure 8, p. 22 and Figure 9, p. 22. To remove the

dowel pin, first remove the nut on the dowel pin,

place a bushing on the pin, and then reinstall the

nut. As the nut is tightened, the dowel pin should

pull out of its hole; at this point, remove the

compressor/motor assembly.

Compressor Motor Mount

Disassembly

If additional vertical clearance is required, the height of

the compressor motor mount can be reduced. Use the

following procedure:

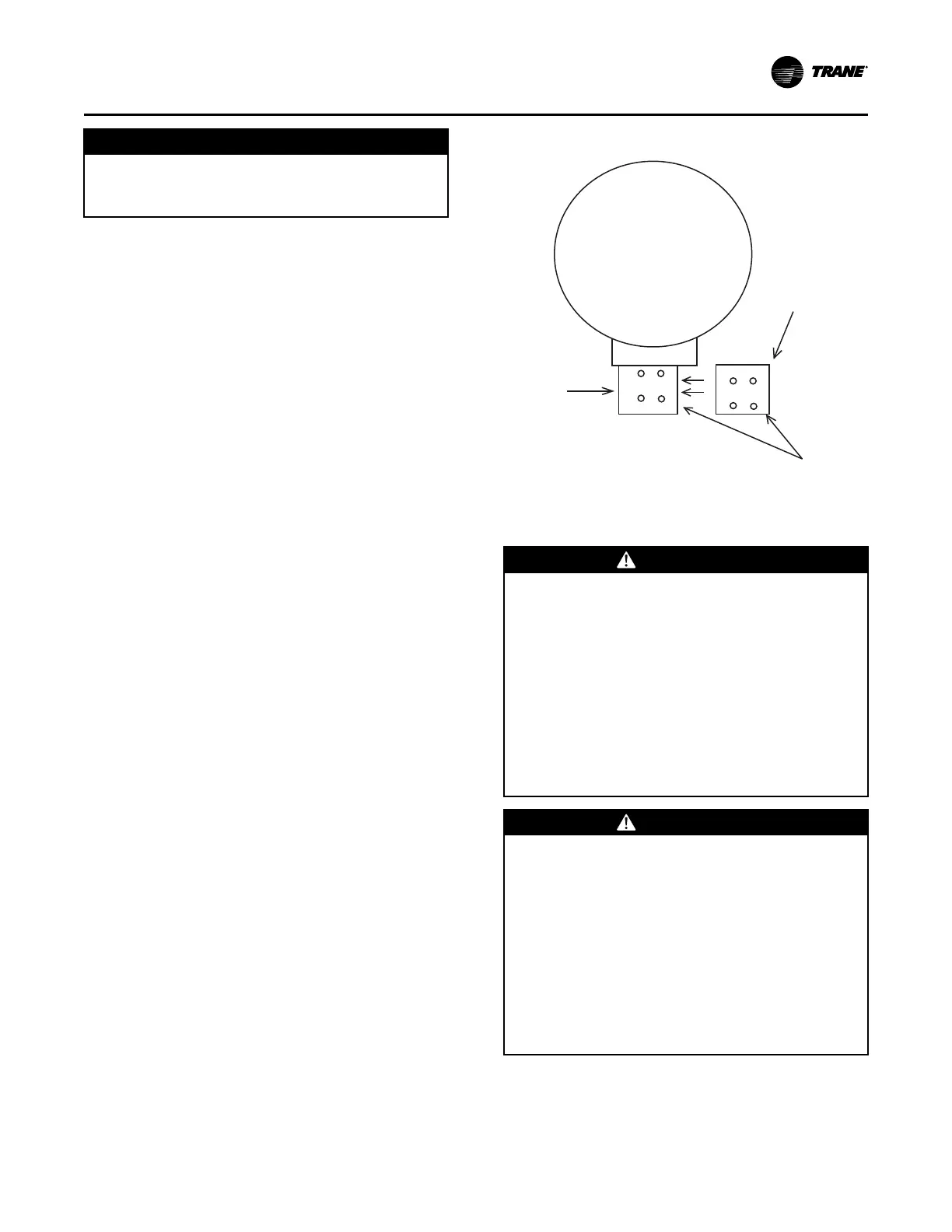

1. Before cutting off the motor mount, first fabricate a

1/4-inch steel backing plate.

a. Cut the backing plate to shape and clamp it to

the motor mount.

b. Drill four 1/4-inch holes through the motor

mount and the backing plate as shown in Figure

16, p. 25. These holes with bolts or roll pins

installed will be used to align the components

during reassembly.

c. Remove the backing plate.

2. Using an oxyacetylene torch, cut the mount as

shown in Figure 16, p. 25.

During reassembly, use the backing plate with bolts or

roll pins to locate the pieces properly. After the pieces

are located, Trane recommends welding the mount and

backing plate in place.

Figure 16. Motor support detail

Cut Here

Compressor Motor

1/4-inch Steel

Alignment

Backing Plate

Bolt Holes

Economizer Removal

WWAARRNNIINNGG

RReeffrriiggeerraanntt MMaayy BBee UUnnddeerr PPoossiittiivvee

PPrreessssuurree!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

aann eexxpplloossiioonn wwhhiicchh ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy oorr eeqquuiippmmeenntt ddaammaaggee..

SSyysstteemm ccoonnttaaiinnss rreeffrriiggeerraanntt aanndd mmaayy bbee uunnddeerr

ppoossiittiivvee pprreessssuurree;; ssyysstteemm mmaayy aallssoo ccoonnttaaiinn ooiill..

RReeccoovveerr rreeffrriiggeerraanntt ttoo rreelliieevvee pprreessssuurree bbeeffoorree

ooppeenniinngg tthhee ssyysstteemm.. SSeeee uunniitt nnaammeeppllaattee ffoorr

rreeffrriiggeerraanntt ttyyppee.. DDoo nnoott uussee nnoonn--aapppprroovveedd

rreeffrriiggeerraannttss,, rreeffrriiggeerraanntt ssuubbssttiittuutteess,, oorr nnoonn--

aapppprroovveedd rreeffrriiggeerraanntt aaddddiittiivveess..

WWAARRNNIINNGG

HHeeaavvyy OObbjjeecctt!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

uunniitt ddrrooppppiinngg wwhhiicchh ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy,, aanndd eeqquuiippmmeenntt oorr pprrooppeerrttyy--oonnllyy

ddaammaaggee..

EEnnssuurree tthhaatt aallll tthhee lliiffttiinngg eeqquuiippmmeenntt uusseedd iiss

pprrooppeerrllyy rraatteedd ffoorr tthhee wweeiigghhtt ooff tthhee uunniitt bbeeiinngg

lliifftteedd.. EEaacchh ooff tthhee ccaabblleess ((cchhaaiinnss oorr sslliinnggss)),, hhooookkss,,

aanndd sshhaacckklleess uusseedd ttoo lliifftt tthhee uunniitt mmuusstt bbee ccaappaabbllee

ooff ssuuppppoorrttiinngg tthhee eennttiirree wweeiigghhtt ooff tthhee uunniitt.. LLiiffttiinngg

ccaabblleess ((cchhaaiinnss oorr sslliinnggss)) mmaayy nnoott bbee ooff tthhee ssaammee

lleennggtthh.. AAddjjuusstt aass nneecceessssaarryy ffoorr eevveenn uunniitt lliifftt..

1. Support the weight of the economizer with a

movable floor jack. Do not lift the economizer;

simply support it. Economizer weights are provided

in Table 10, p. 18; also see submittal. It is

DDiissaasssseemmbbllyy

Loading...

Loading...