CGAD-SVN02C-EN10

Clearance between Units and

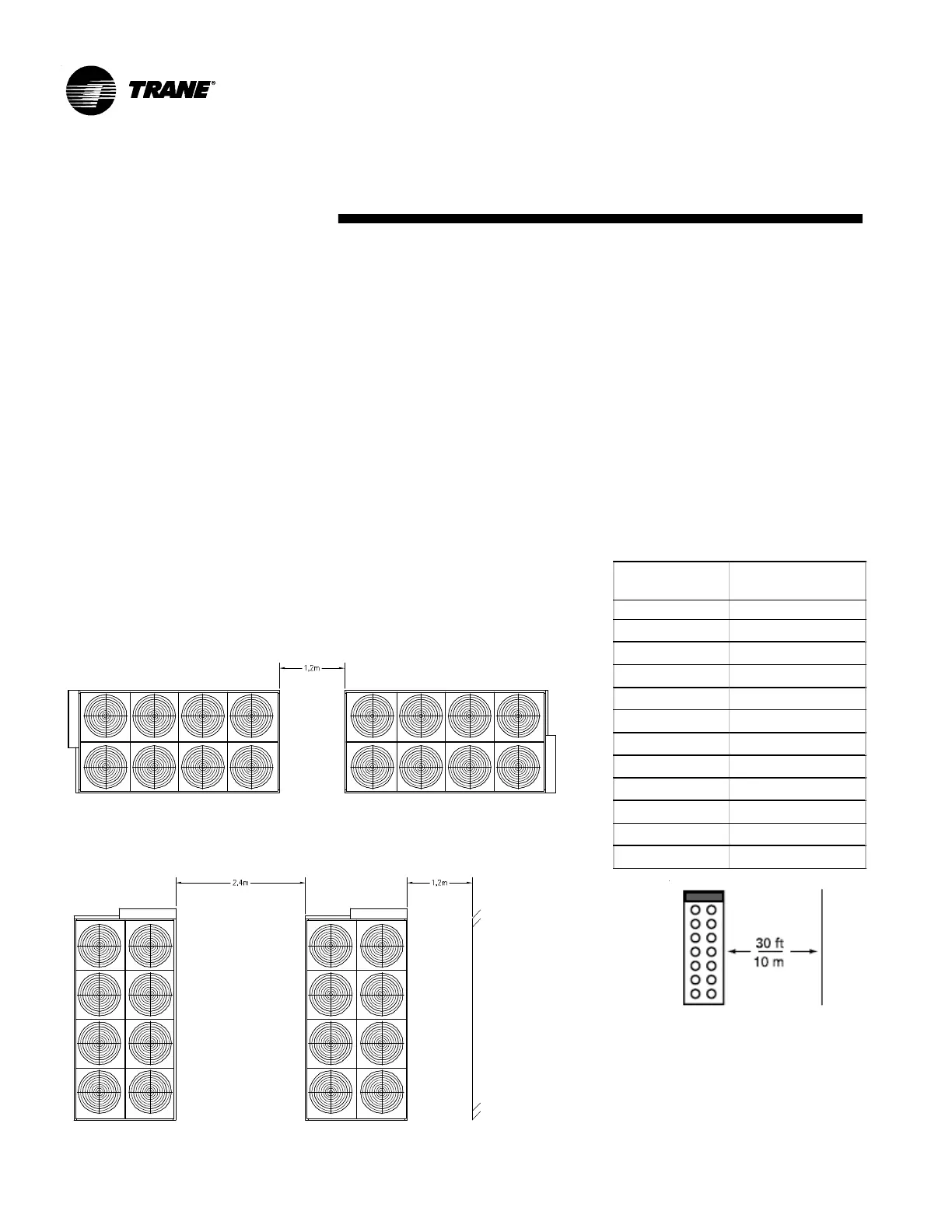

Sound Pressure (dBA)

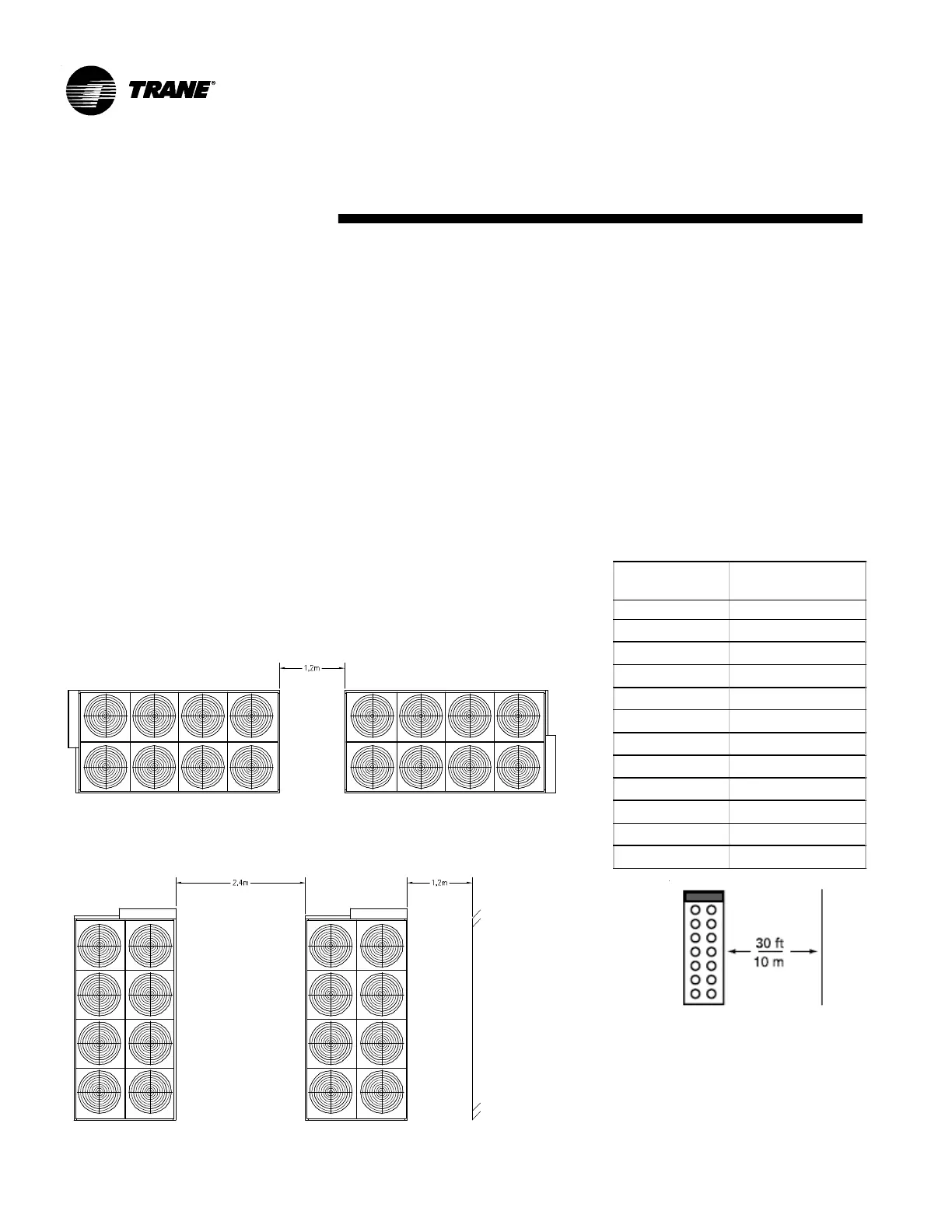

Make sure that there is enough space

around the unit externally in order to allow

the installation and maintenance team to

have unrestricted access to all service

points. Check the unit's dimensions in the

drawings that were approved. We

recommend a minimum of 4 feet (1.2 m)

for servicing the compressor. Make sure

there is enough space to open the control

panel doors. Above all, any local codes that

determine additional spaces needed have

priority over these recommendations.

The warm air recirculation and the

depletion of the coil cause a reduction in

the unit's efficiency and capacity due to an

increase in the charge pressures. Do not

allow residues, trash, and other materials

to accumulate around the unit. The

Fig. 05b - Recommended clearances - between units

Fig. 05a - Recommended clearances - horizontal assembly

CGA D020C 64

CGA D025C 65

CGA D030C 65

CGA D040C 67

CGA D050C 68

CGA D060C 68

CGA D070C 70

CGA D080C 72

CGA D090C 72

CGA D100C 72

CGA D120C 74

CGA D150C 74

Pr es s ão Sonor a

(dbA) a 10 m e tros

Equipam ento

Notes: Measurements are made on the side of

equipment at distance of 10 meters. Measurements

smaller than 10 meters may provide diferents results

because the large size of equipment and different

sources of noise located in defferent positions.

movement of air supply can cause

residues to be sucked up into the

condenser coil and block the spaces

between the fins of the coil and cause the

coil to become depleted. The units for low

ambient temperatures need special

attention. The coils of the condensers and

the discharge of the fans should be kept

free of snow and of other obstructions to

allow an adequate air flow and a

satisfactory operation.

In situations in which the equipment has to

be installed with less space than that

recommended, which frequently occurs in

applications with retroactive updates and

with ceiling assemblies, a restricted air

flow is common.

An unobstructed air flow for the condenser

is essential to maintain the chiller's

operational capacity and efficiency. When

deciding on the unit's position, plan

carefully in order to ensure enough air flow

through the condenser's heat transfer

surface. Two possible harmful conditions

must be avoided for the equipment to

reach its optimum performance: warm air

recirculation and the depletion of the coil.

Warm air recirculation occurs when the

discharge air from the condenser fans is

blown to the entrance of the condenser

coil. The coil's depletion occurs when the

free air-flow (or part of it) to the condenser

is restricted.

Loading...

Loading...