CGAD-SVN02C-EN22

Periodic Preventive Maintenance

Carry out all the maintenance inspections

and services at the recommended

intervals. This will prolong the equipment's

durability and will reduce the possibility of

the equipment failing.

Use the "Operational Reading Datasheet"

to record on a weekly basis the operational

conditions for this unit. The sheet with the

operational data could be a valuable

diagnostic tool for the technical assistance

team. By writing down trends of the

operating conditions, the operator can

frequently foresee and avoid problem

situations before they become serious. If

the unit does not operate correctly, go to

"Troubleshooting".

Weekly Maintenance

Once the equipment has been operating

for approximately 10 minutes and the

system is stabilized, check the operational

conditions and follow this checklist of

procedures:

[ ] Check the oil level in the compressors.

The oil level should be visible at the sight

glass of the casing when the compressor

is working. Operate the compressor for at

least 3 or 4 hours before checking the oil

level and then check it every 30 minutes. If

the oil has not reached to an adequate

level after this period, a qualified technician

should add or remove oil. Check on Table

4 the recommended charges of refrigerant

and of oil.

[ ] Check the suction and discharge

pressures in the unit's pressure gauges.

Read "Checking Operational Conditions"

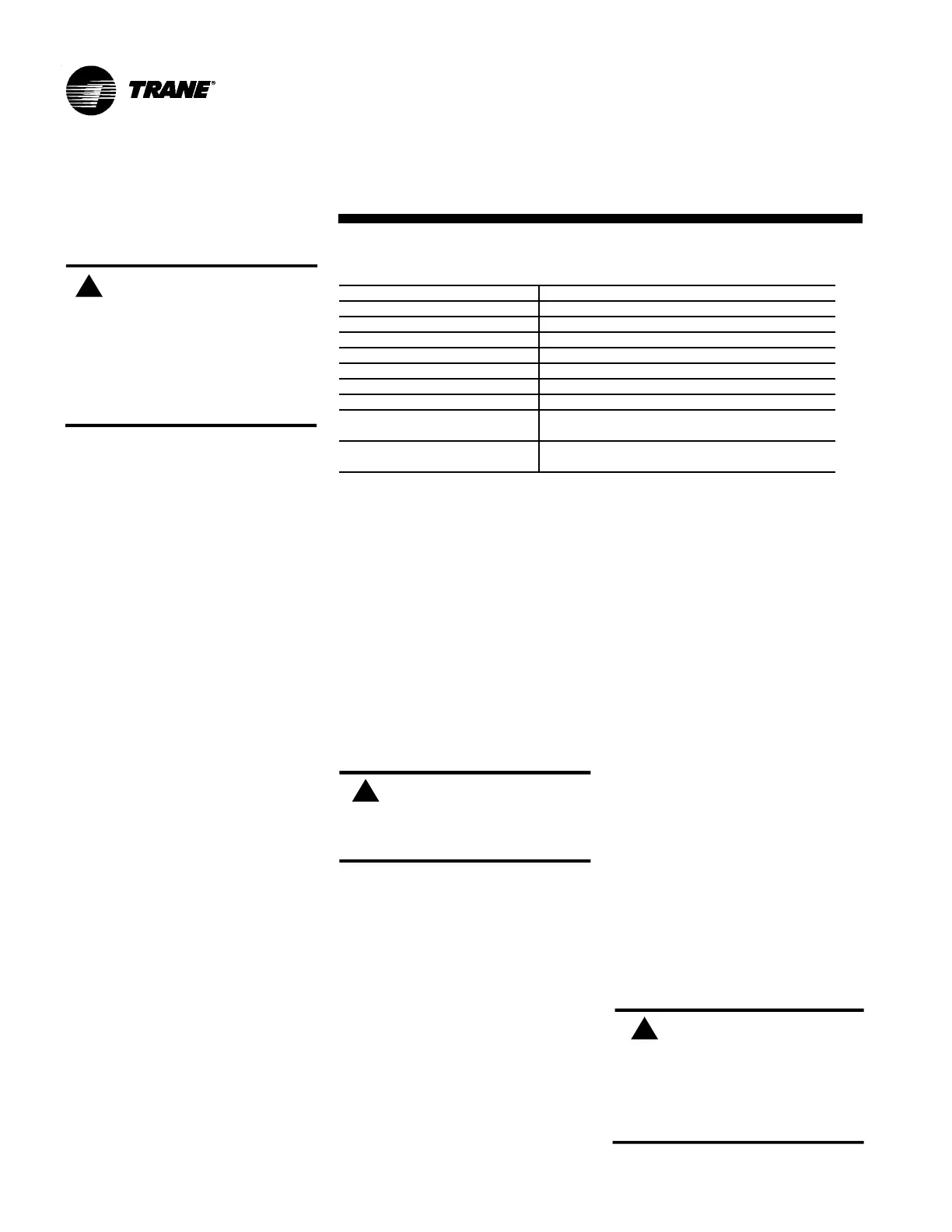

Oil level Visible when compressor is running

High pressure 200 to 340 psig

Lowpressure 55 to 80 psig

Overheating from 6 to 10°C

Subcooling from 5 to 10°C

Liquid sight glass Refrigerant flow without gas traces

Voltage M ust not excede +/-10%of nameplate voltage

Current M ust not be over nameplate current

Evaporation temperature

- 2,0°C to +8 C. Normal value = 5°C below chilled water

leaving temperature.

Condensing temp.(Air-Cond) 38°C to 60°C . Normal value 20°C above entering air temp.

Operational

Procedures

Table 07 - Overheating and subcooling adjustmen7

[ ] Check the liquid line sight glass. Read

"Checking Operational Conditions"

[ ] If the operational conditions and the

liquid sight glass indicate a lack of gas,

measure the system's superheat and

subcooling. See items "Superheat of the

system" and "Subcooling of the system".

[ ] If the operational conditions indicate an

overcharge, then slowly (to minimize the

losses of oil) remove refrigerant through

the service valve located on the liquid line.

[ ] Inspect the system in order to detect

Annual Maintenance

[ ] Do all the services listed for weekly and

monthly recommended maintenance.

[ ] Have a qualified technician check the

calibration and operation of each control

and inspect and replace any contacts or

controls if needed.

[ ] If the chiller does not have a tube drain,

be sure that the drain is clean for draining

all the water.

[ ] Drain the system's condenser and

evaporator water and tubing. Inspect all the

components for leaks and damages.

Clean all water filters.

[ ] Inspect the condenser tubes and clean

if necessary.

[ ] Clean and repair any surface that is

corroded.

[ ] Inspect the expansion valve bulb and

see if it needs cleaning. Clean if

necessary.

The bulb should have an excellent contact

with the suction line and be appropriately

insolated.

abnormal conditions. Use the reading

datasheet as mentioned to weekly record

the unit's conditions. A reading datasheet

that is filled out is a valuable tool for the

technical assistance team.

Monthly Maintenance

[ ] Do all the services listed for weekly

maintenance.

[ ] Measure and record the system's

superheat.

[ ] Measure and record the system's

subcooling.

CAUTION:

All the tests done on the pressure

regulators should be done with

reliable pressure gauges. These

safety devices are calibrated at the

factory and sealed. If violated, the

warranty will be void.

!

To avoid accidents from freezing,

don't let your skin com in contact

with the refrigerant.

CAUTION:!

CAUTION:!

All the tests done on the pressure

switches should be done with reliable

pressure gauges. These safety devices

are calibrated at the factory and sealed.

If violated, the warrantywill be void.

Loading...

Loading...