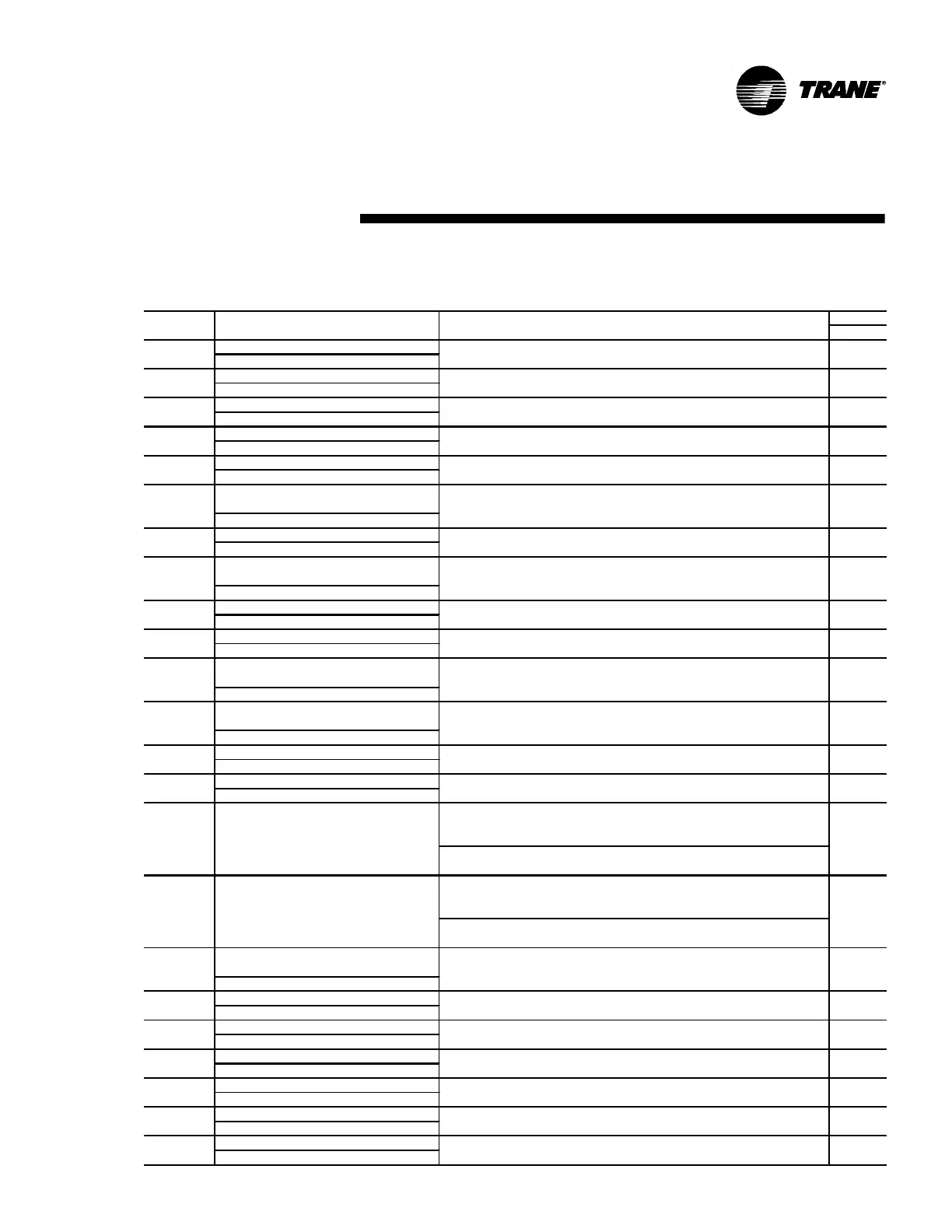

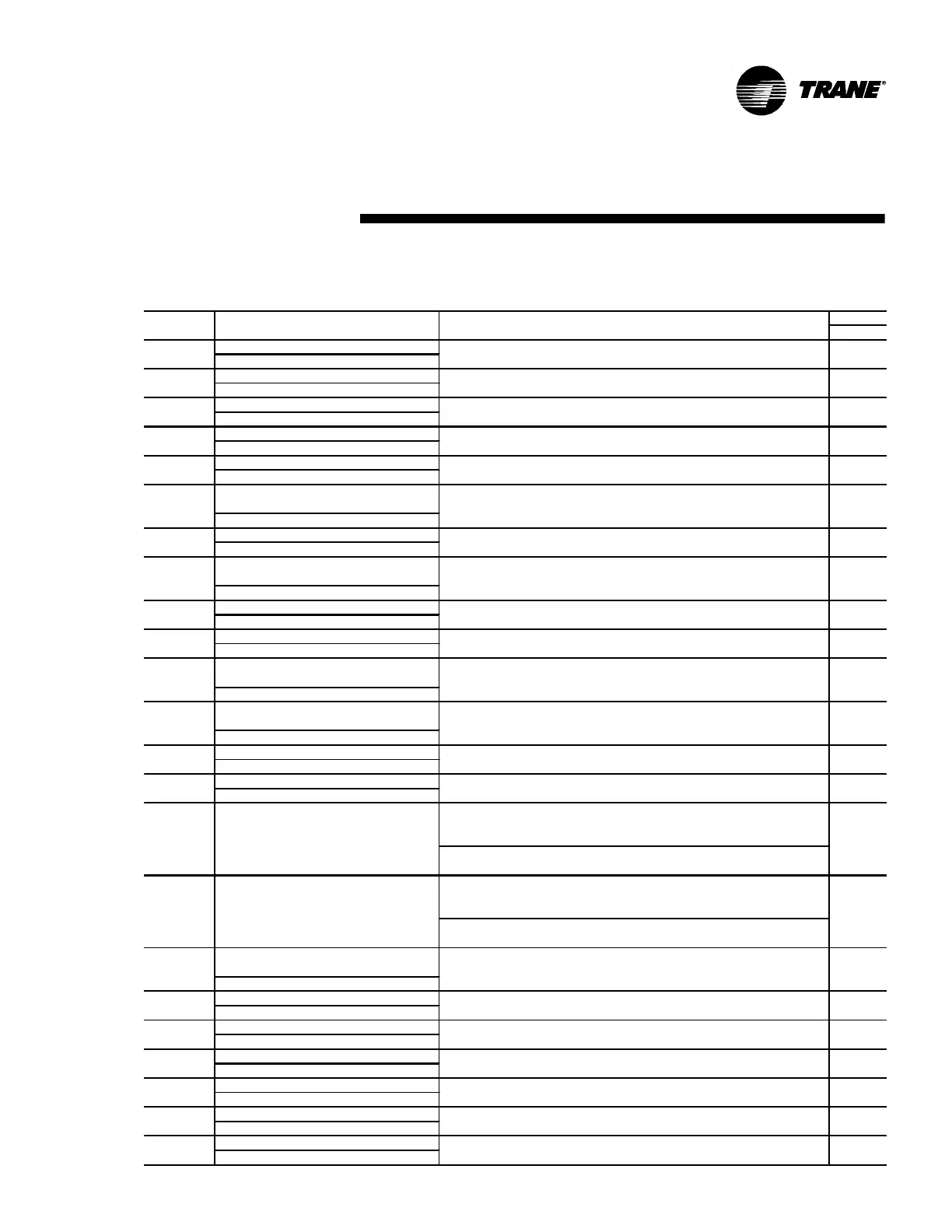

CGAD-SVN02C-EN 73

Type

Reset

Phase Reversal

Current L1Loss

Current L2 Loss

Current L3 Loss

Starter Module M emory Error Type 2

Power Loss

Starter Contactor Interrupt Failure

M P: Reset Has Occurred

Low Pressure Cutout

Low Suction Refrigerant Pressure

High M otor Temp/Overload Trip Cprsr A

High M otor Temp/Overload Trip Cprsr A

BAS Failed to EstablishCommunication

BAS Communication Lost

A. The external control module of the chilled water temperature setpoint received a

control voltage or current aboveor below the specified limits. (0 to 10 VDC or 4 to 10

ma).

B. The control module presented an operational failure or there is a bad contact on the

connection cable of the modules (LLID).

A. When activated, the operational reclaiming normally is interrupted by the low

pressure control. This message indicates that the low pressure control did not detect a

low pressure of 10PSI after 30 seconds after the beginning of the reclaiming.

When the reclaiming service is activated, the low pressure control did not detect a low

pressure of 10PSI after 1minute from thebeginning of the reclaiming.

Chilled Water Flow (Entering Water Temp)

Evaporator Entering Water Temp Sensor

Evaporator Leaving Water Temp Sensor

Condenser Entering Water Temp Sensor

Condenser Leaving Water Temp Sensor

Discharge Pressure Transducer

Suction Pressure Transducer

Code Diagnostic Description of Pr oblem

E5 A phase reversal was detected on the equipment's energy supply. Local

E4 The L1current sensor detected a loss of current. Local

E4 The L2 current sensor detected a loss of current. Local

E4 The L3 current sensor detected a loss of current. Local

6B6 Detecting error in the configuration in the starter module memory of the compressors. Local

1A0 The current sensors detected a three-phase power loss during the operation. If the

current is less than 10%of the nominal current, the equipment will shut down in 2.64

seconds.

Remote

CA A current level 10%higher than the maximumcurrent of operation for the equipment was

detected on one or more phases of the three-phase power supply.

Local

D9 The controller was reset after receiving a new configuration and installation of a new

version of the control software. This message is automatically deactivated and only

visualized through the log of diagnostics.

NA

B5 or B6 The equipment's suction pressure dropped below 7 psi, causing the compressor(s) to

turn off.

Local

6B6 A suction pressure below that specified for the protection system was detected. This

diagnostic will be automatically reset when thepressure reaches adequate values.

Local

BA or BC The internal thermostat of the compressor identified a high temperature or the

protection against the compressor's overload detected a current level above the

protection level established.

Local

BB or BD The internal thermostat of the compressor identified a high temperature or the

protection against the compressor's overload detected a current level above the

protection level established.

Local

390 The controller was informed that it is linked to the Management System(BAS) and

cannot make communication with it.

Remote

398 The COM M3 communication module of the controller lost communication with the

Management System(BAS)

Remote

87 External Chilled Water Setpoint Remote

8C or 8D Circuit Pumpdown Terminated Remote

Remote

8E Temperature sensor has a defect or abad contact on the connection cable of the

sensors.

Remote

8A It was detected that the temperature of the entering water fromthe evaporator is 3.6ºC

below the evaporator's leaving water temperature, which indicates a lack of water flow

through the evaporator.

AB Temperature sensor has a defect or a bad contact on the connection cable of the

sensors.

Remote

9A Temperature sensor has a defect or a bad contact on the connection cable of the

sensors.

Remote

9B Temperature sensor has a defect or a bad contact on the connection cable of the

sensors.

Remote

6B6 Pressure transducer has a defect or a bad contact on the connection cable of the

sensors.

Remote

6B6 Pressure transducer has a defect or a bad contact on the connection cable of the

sensors.

Remote

Diagnostics

CH 530

Loading...

Loading...