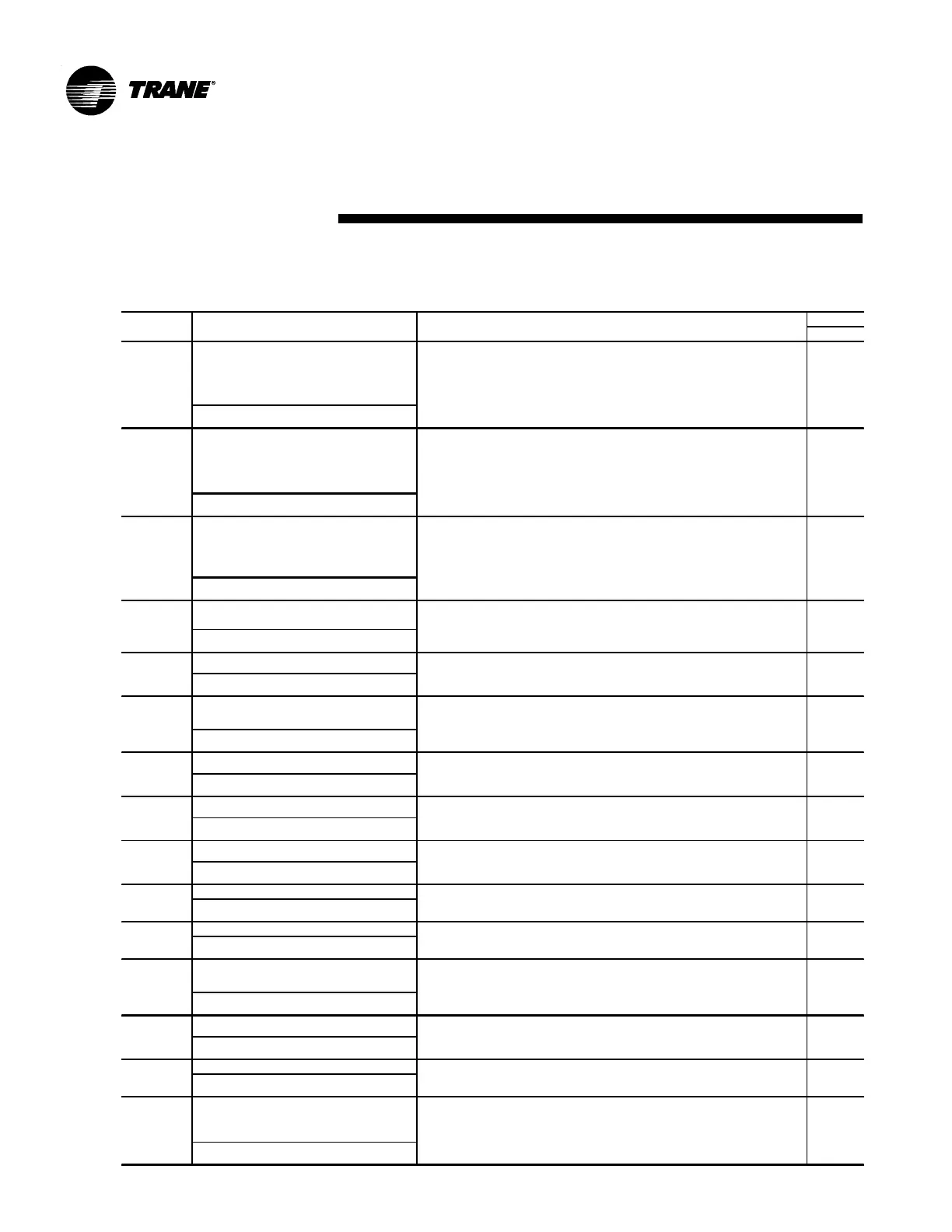

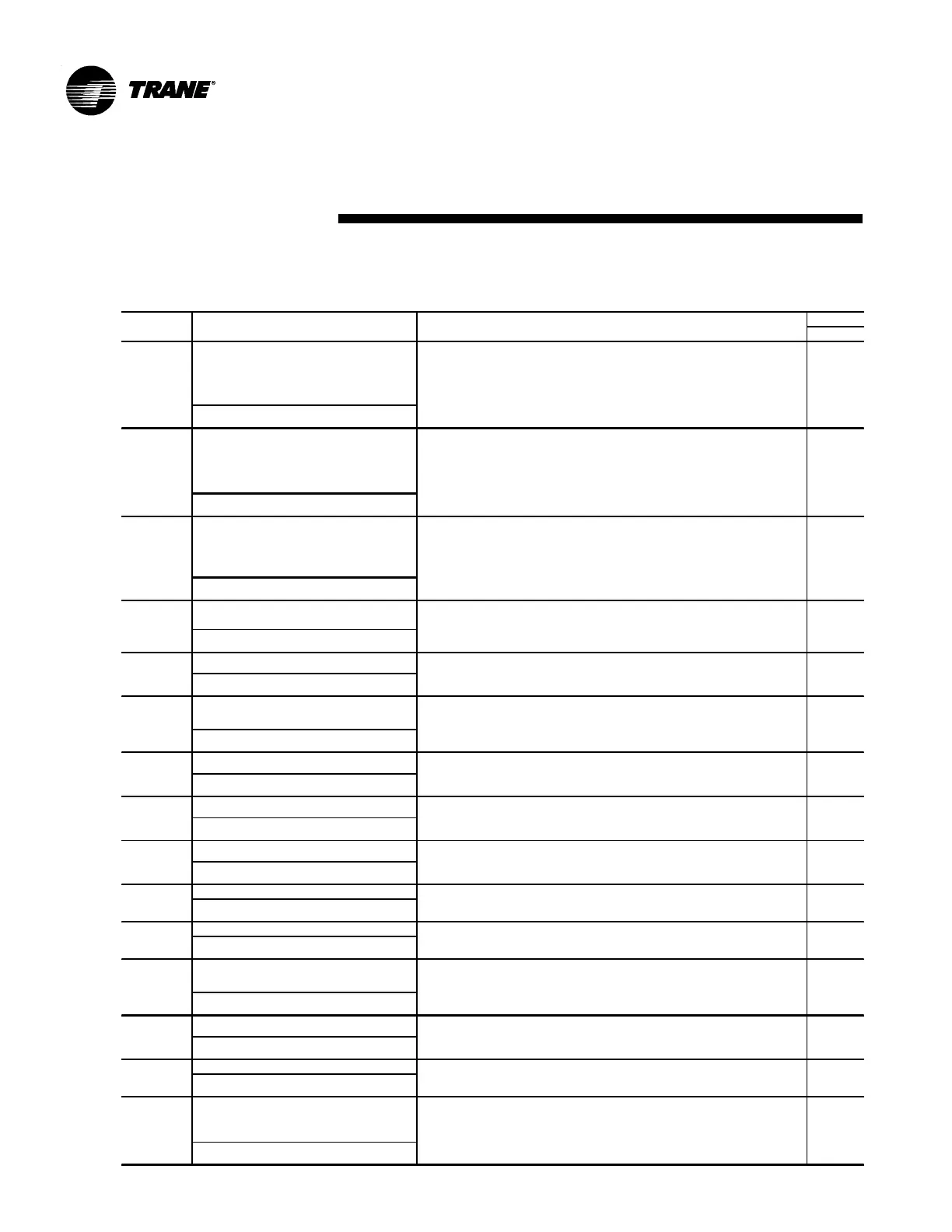

CGAD-SVN02C-EN74

Type

Reset

Low Evap Leaving Water Temp: Unit Off

Low Evap Leaving Water Temp: Unit On

High Evaporator Water Temperature

Evaporator Water Flow Overdue

Evaporator Water Flow Lost

Condenser Water Flow Overdue

Condenser Water Flow Lost

High Pressure Cutout

Emergency Stop

Outdoor Air Temp Sensor

MP: Non-Volatile Memory Reformatted

Check Clock

MP: Could not Store Starts and Hours

MP: Non-Volatile Block Test Error

Starts/Hours Modified - Compressor X

C5 It was detected that the leaving water temperature of the evaporator is 3.6ºC below the

anti-freezing protection temperature at the moment when all thecompressors are turned

off. The auto reset should occur whenthe water temperature reaches 3.6°C above the

anti-freezing protection temperature.

Remote

Code Diagnostic Description of Problem

C6 It was detected that the leaving water temperature of the evaporator is 3.6ºC below the

anti-freezing protection temperature at the moment when one or more compressors are

turned on. The auto reset should occur when the water temperature reaches 3.6°C above

theanti-freezing protection temperature.

Remote

6B6 Evaporator Leaving Water Temperature is above 46ºC. This message will automatically

be erased when the leaving water temperature drops below 43ºC. This diagnostic has

thepurposeof protecting the evaporator fromdamage due to high water temperature

inside of it. The water pump should not operatewhile this diagnostic is active.

Local

384 Water flow in the evaporator was not detected by the contact of the flow switch. This

diagnostic will be automatically reset when the water flow is reestablished.

Remote

ED After the presenceof water flow was established inthe evaporator, a posterior lack of

water flow was detected by the flow switch.

Remote

DC Water flow in the condenser was not detected by the contact of the flow switch. This

diagnostic will be automatically reset when the water flow is reestablished.

Remote

F7 After thepresence of water flow was established inthe condenser, a posterior lack of

water flow was detected by the flow switch.

Remote

F5 The high-pressureswitchwas kept open for more than 3 seconds. Local

FD The controller received asignal to turn off the equipment fromthe Emergency Stop

module.

Local

A1 Temperature sensor has a defect or a bad contact on the connection cable of the

sensors.

Remote

1AD The controller detected an error in its non-volatile memory and reformatted it. The

configurations of the controller should be checked.

Remote

2,00E+06 An operational failure of the controller's internal clock was detected. Check theclock's

battery and change if needed. This diagnostic will be automatically erased when the

clock is corrected.

Remote

1D1 It was detected that there was a failure in the storage on the compressors' number of

starts and number of hours in operation due to power loss. The data related to the last

24 hours most likely were lost.

Remote

1D2 An error was detected on oneof the controller's non-volatile memory block. Check the

configurations of the controller.

6B6 The compressor's counter of number of starts and number of hours in operation was

modified by TechView. The diagnostic will indicate to which compressor belongs the

modified counter. This message is immediately reset and will only be able to be viewed

in the log of diagnostics.

NA

Diagnostics

CH 530

Loading...

Loading...