CGAD-SVN02C-EN 15

Application

Considerations

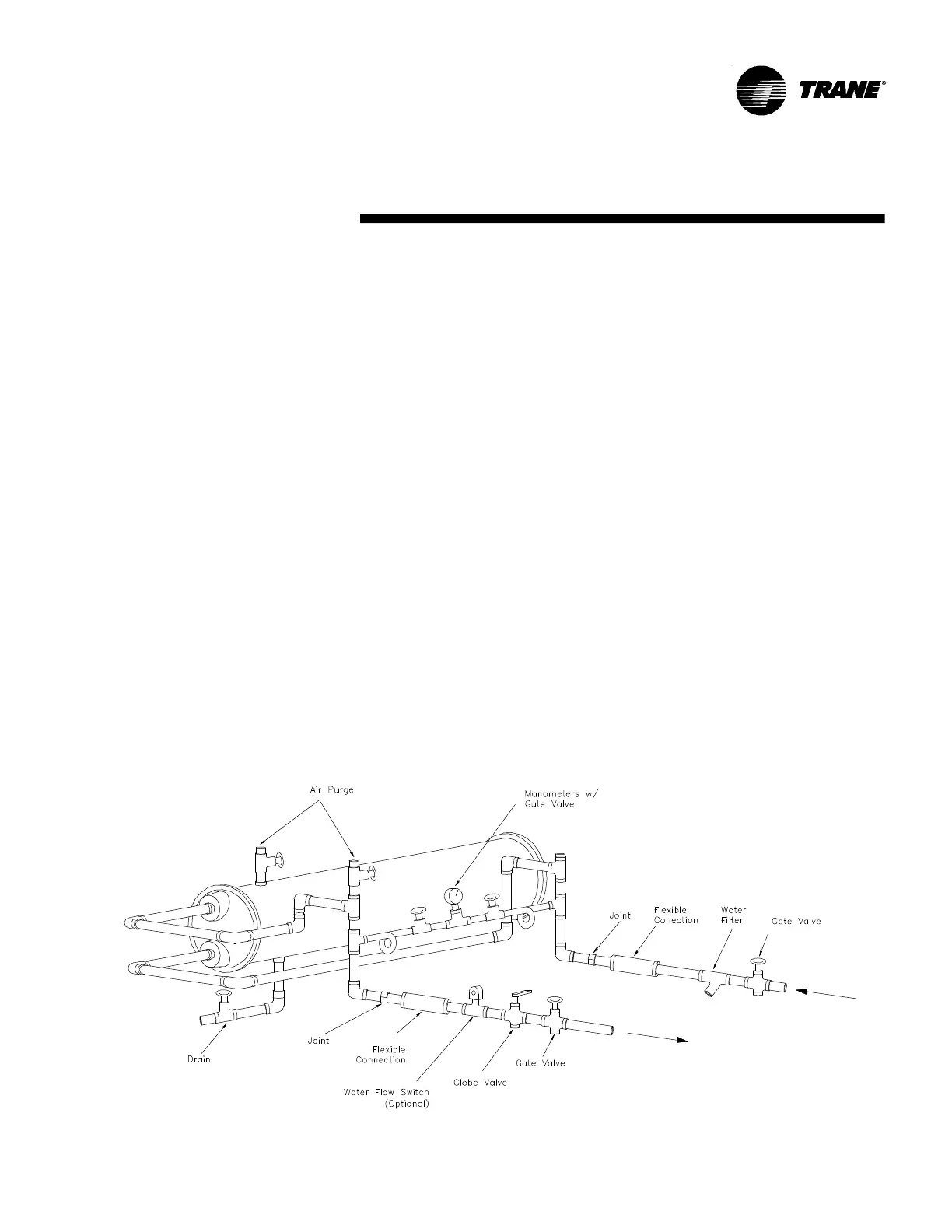

Components of the Hydraulic Tubing of

the Evaporator

The figure below shows how to proceed to

install the water tubing. An air escape valve

is placed on the top part of the evaporator

and leaving water. Provide additional air

escape valves at the highest points of the

tubing in order eliminate it from the chilled

water system.

Drain of the Evaporator

The evaporator discharge connection

should be close to an available drain in

order to empty out the evaporator even

during the service. Install a slide valve on

the drain line.

Thermometers and Pressure Gauges

The installation of thermometers (items 5

and 12 of the figure) and pressure gauges

(item 9) is essential at the inlet and outlet

of chilled water. These instruments should

be installed close to the unit and have the

maximum scale of 1

o

C for thermometers

and of 0.1 kg/cm

2

for pressure gauges.

Important: In order to avoid damaging the

evaporator, do not let the water pressure

exceed 150 psig.

We recommend installing a pressure

gauge with a connection at the water inlet

and outlet similar to item 9 in the figure in

order to avoid reading errors. The

installation of the pressure gauges and

thermometers should be at a height to

avoid parallax errors*. The thermometers

should also be of glass or mercury

scaling with colored fluid for contrast

purposes and to make reading them

easier.

- The pressure gauges should be

designed with siphons.

- Install slide valves in order to isolate the

pressure gauges when they are not being

used.

Use joints on the tubing in order to

facilitate the mounting and dismounting

services.

The inlet and outlet should have slide

valves in order to insolate the evaporator

during the execution of services and a

globe valve at the outlet to regulate the flow

of water.

Flow-Switch

Check the safety interlocking, especially

the flow-switch should be installed along

straight and horizontal sections with the

fins according to the diameter of the tubing

and the distance of the curves and valves

at least five times its diameter on each

side.

Water Treatment

The use of untreated or poorly treated

water could result in the formation of

scales, erosion, corrosion, algae, and

lime. We recommend that the services of a

water treatment specialist be contracted in

order to determine the treatment and if

needed, to carry it out. Trane do Brasil

does not take any responsibility for failures

with equipment due to using untreated or

poorly treated water.

* Parallax Error: Apparent dislocation of an object when the point of observation is changed. This especially refers to the apparent dislocation of the needle of a measuring instrument when looking at it

from a vertical direction (parallax error).

Fig. 07 - Components of the Hydraulic Tubing of the Evaporator

Loading...

Loading...