Page 67

14.2

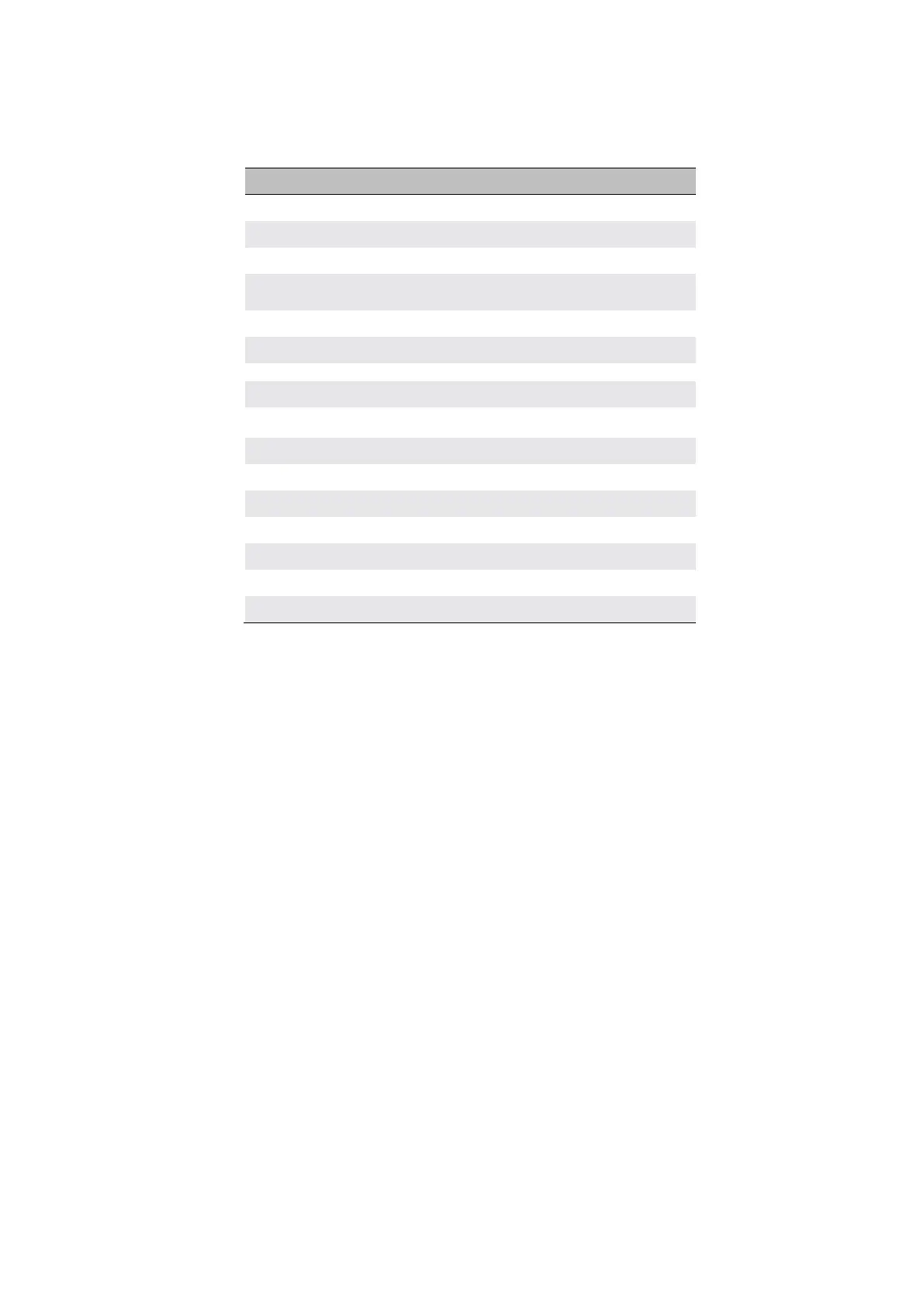

STANDARD CHECKS

Operations description

Compressors oil level check monthly

Inlet temperature check (overheating) monthly

Water circuits filling check monthly

Compressors motors electrical input check monthly

Power supply and auxiliary power voltage check monthly

Refrigerant charge check through sight glass monthly

Compressors carter heaters operation check

monthly

Tightening all electrical connections monthly

Compressors and liquid circuit solenoid valve

check

semiannual

Compressors contactors state check quarterly

Evaporator heater operation check quarterly

Pressure vessels conditions check yearly

Check glycol concentration in the chilled water

circuit if glycol presence is required

monthly

Check and clean the strainer monthly

Check operation of all safety devices annual

Carry out oil analysis and change the oil if

necessary

annual

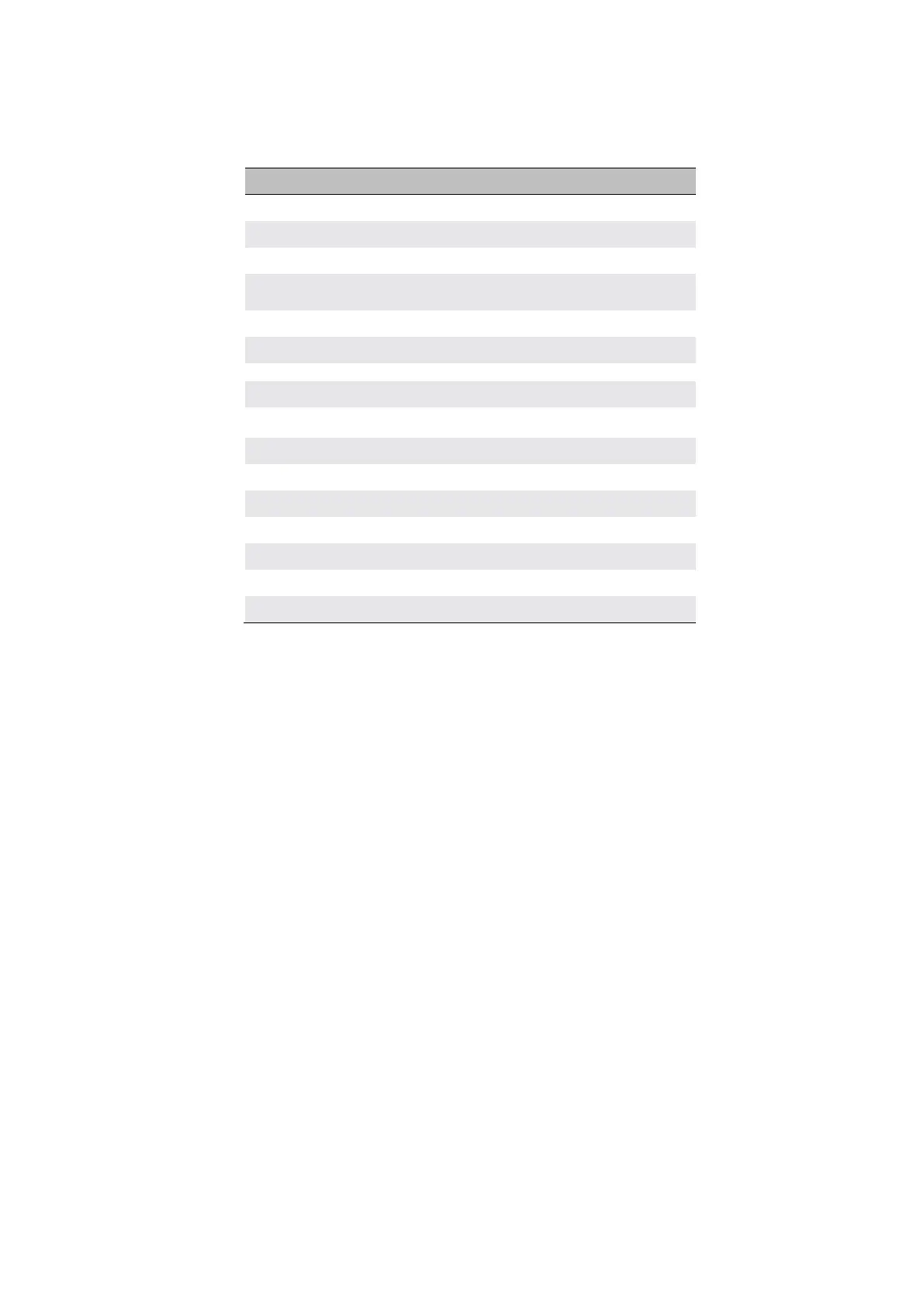

Temperature and pressure probes –

The unit comes factory-equipped with all the sensors listed below. Periodically

check that their measurements are correct by means of sample instruments (manometers, thermometers); correct

readings if necessary using the microprocessor keyboard. Well- calibrated sensors ensure better efficiency for the unit and

a longer lifetime.

Note: refer to the microprocessor use and maintenance manual for a complete description of applications, setting and

adjustments.

All sensors are preassembled and connected to the microprocessor. The descriptions of each sensor are listed below:

Evaporator outgoing water temperature sensor –

This sensor is located on the evaporator outgoing water connection

and is used

by the microprocessor

for antifreeze protection and

to control the unit load according to the system thermal

load

.

IMPORTANT

In case a temperature control based on ingoing water temperature is needed please contact Trane before carrying

out any trying to set it autonomously

.

Evaporator ingoing water temperature sensor –

This sensor is located on the evaporator ingoing water connection

and is used for monitoring the return water temperature.

Condenser outgoing water temperature sensor –

This sensor is located on the condenser ingoing water connection

and is used for monitoring the condenser delivery water temperature.

Condenser ingoing water temperature sensor –

This sensor is located on the condenser ingoing water connection

and is used for monitoring the condenser return water temperature.

External air temperature sensor –

This sensor allows to monitor the external air temperature on the microprocessor

display and to manage the activation/deactivation of the compressors crankcase heaters

High pressure transducer –

This allows to monitor the delivery pressure and to control the ventilators. Should an

increase in condensation pressure occur, the microprocessor will control the circuit load in order to allow it to function even

if choked. It contributes to complementing the oil control logic.

Low-pressure transducer –

This allows to monitor the compressor suction pressure along with low pressure alarms. It

contributes to complement the oil control logic and to manage the electronic expansion valve.

Suction temperature sensor –

This allows to monitor the compressor suction temperature. It contributes to manage

the electronic expansion valve.

Compressor discharge temperature sensor –

This allows to monitor compressor discharge temperature and oil

temperature. The microprocessor shuts down the compressor in case of alarm in the event that the discharge temperature

reaches 120°C.

Loading...

Loading...