28

PRGD-SVX01F-EN

Troubleshooting

Use this section to assist you in diagnosing operational

problems with the purge system.

WWAARRNNIINNGG

RReeffrriiggeerraanntt uunnddeerr HHiigghh PPrreessssuurree!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

aann eexxpplloossiioonn wwhhiicchh ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy oorr eeqquuiippmmeenntt ddaammaaggee..

SSyysstteemm ccoonnttaaiinnss ooiill aanndd rreeffrriiggeerraanntt uunnddeerr hhiigghh

pprreessssuurree.. RReeccoovveerr rreeffrriiggeerraanntt ttoo rreelliieevvee pprreessssuurree

bbeeffoorree ooppeenniinngg tthhee ssyysstteemm.. SSeeee uunniitt nnaammeeppllaattee ffoorr

rreeffrriiggeerraanntt ttyyppee.. DDoo nnoott uussee nnoonn--aapppprroovveedd

rreeffrriiggeerraannttss,, rreeffrriiggeerraanntt ssuubbssttiittuutteess,, oorr rreeffrriiggeerraanntt

aaddddiittiivveess..

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr bbeeffoorree sseerrvviicciinngg ccoouulldd

rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy..

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss bbeeffoorree sseerrvviicciinngg.. FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaann nnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd.. VVeerriiffyy tthhaatt nnoo

ppoowweerr iiss pprreesseenntt wwiitthh aa vvoollttmmeetteerr..

WWAARRNNIINNGG

HHoott SSuurrffaaccee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

sseevveerree bbuurrnnss..

SSuurrffaaccee tteemmppeerraattuurreess mmaayy eexxcceeeedd 330000°°FF ((115500°°CC))..

TToo aavvooiidd ppoossssiibbllee sskkiinn bbuurrnnss,, ssttaayy cclleeaarr ooff tthheessee

ssuurrffaacceess.. IIff ppoossssiibbllee,, aallllooww ssuurrffaacceess ttoo ccooooll bbeeffoorree

sseerrvviicciinngg.. IIff sseerrvviicciinngg iiss nneecceessssaarryy wwhhiillee ssuurrffaaccee

tteemmppeerraattuurreess aarree ssttiillll eelleevvaatteedd,, yyoouu MMUUSSTT ppuutt oonn

aallll PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE))..

Diagnostics

The chiller controller generates diagnostics to alert the

operator to abnormal conditions. There are two kinds

of diagnostics:

• Non-latching diagnostics: Operation continues.

Alarms resolve themselves and the alarm

disappears. They are informational only.

• Latching diagnostics: Operation stops until the

condition is corrected and the diagnostic has been

manually reset from the Tracer® AdaptiView™

display or from the Tracer® TU service tool.

The following table describes the causes of diagnostics

and operating problems that can occur with purge

systems, and suggests solutions to resolving them.

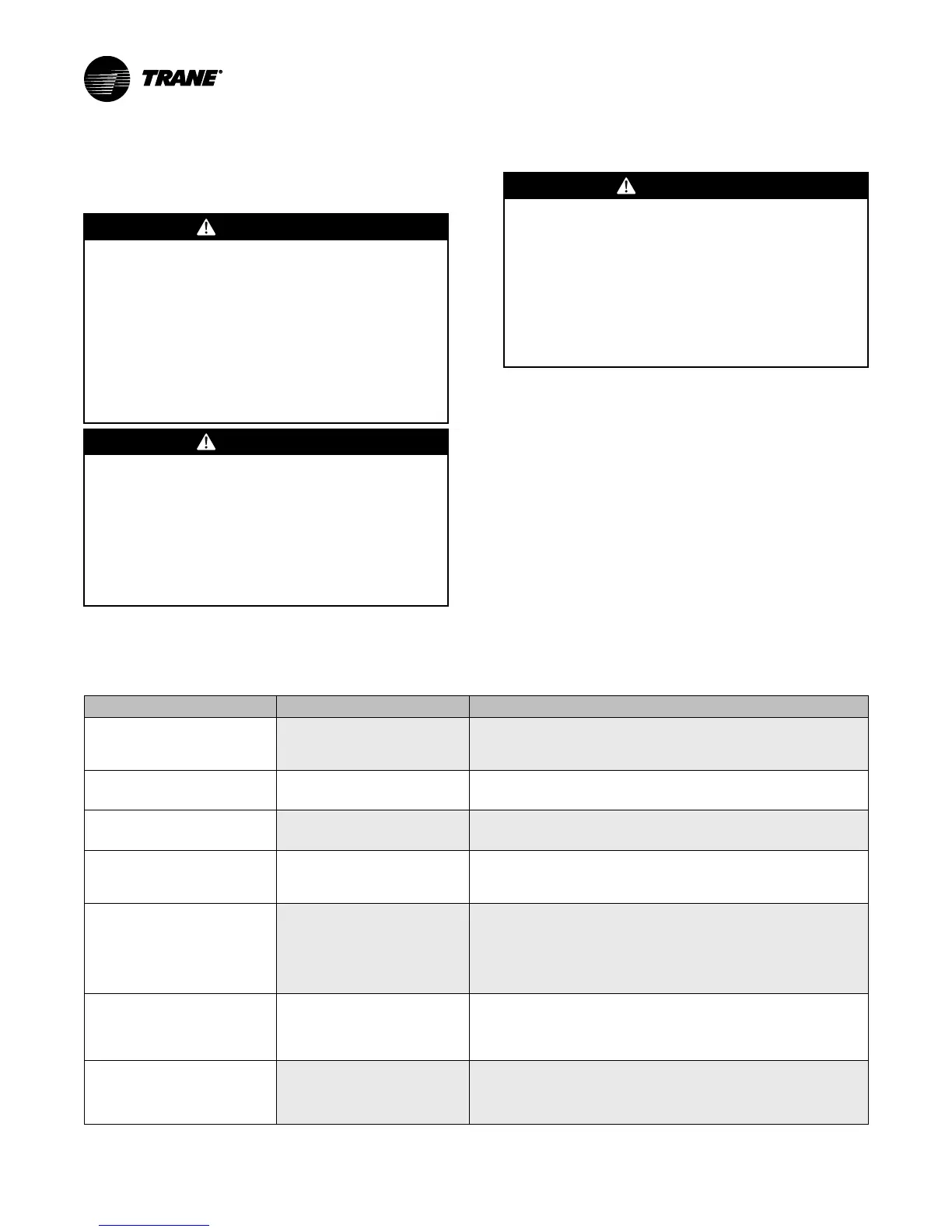

Table 2. Troubleshooting a purge system

Diagnostic or Problem

Cause Solution

Purge Cprsr Suction Temp Sensor

(latching diagnostic)

Bad Sensor or LLID.

The purge refrigerant compressor suction temperature sensor has failed.

The connection has been broken or a short has occurred in the wiring, or

the LLID is not programmed or functioning correctly. Replace or repair as

required.

Purge Liquid Temp Sensor

(latching diagnostic)

Bad Sensor or LLID.

The purge liquid temp sensor has failed. The connection has been broken

or a short has occurred in the wiring, or the LLID is not programmed or

functioning correctly. Replace as required.

Purge Carbon Tank Temp Sensor

(latching diagnostic)

Bad Sensor or LLID.

The purge carbon tank temp sensor has failed. The connection has been

broken or a short has occurred in the wiring, or the LLID is not

programmed or functioning correctly. Replace as required.

Purge Liquid Level Too High (non-

latching diagnostic)

High liquid level in purge tank or

bad level switch. The level switch

was open for at least 20 minutes.

Check for restrictions in the in the vapor pick-up line and in the liquid

return line. Ensure the vapor line is sloped correctly and has no liquid

traps. Change filter drier if required. Ensure the line shutoff valves are

open.

Purge Liquid Level Too High

Continuously (latching diagnostic)

High liquid level in purge tank or

bad level switch. The level switch

was open for more than

20 minutes, or the liquid level/

refrigeration circuit restart cycle

has occurred more than four times

in 4 hours.

Check for restrictions in the in the vapor pick-up line and in the liquid

return line. Ensure the vapor line is sloped correctly and has no liquid

traps. Change filter drier if required. Ensure the line shutoff valves are

open.

Purge Carbon Regen Temp Too

Low (non-latching diagnostic)

The carbon tank temperature did

not increase more than 25°F

(-3.9°C) in the first 2 hours after

energizing the carbon tank heater.

This diagnostic is intended to identify a failed heater or sensor. Check

carbon tank heater and heater wiring. Check the carbon tank

temperature sensor and its wiring. Check the carbon tank insulation and

the surrounding ambient temperature. Check the purge unit controls and

settings.

Carbon Regeneration Temperature

Setpoint Not Satisfied (non-

latching diagnostic)

The carbon tank temperature

sensor did not reach the minimum

regeneration temperature setpoint

within 4 hours after energizing the

heater.

This is intended to identify a failing insulation system. Check carbon tank

insulation for integrity. Check ambient conditions. Check heater

operation.

Loading...

Loading...