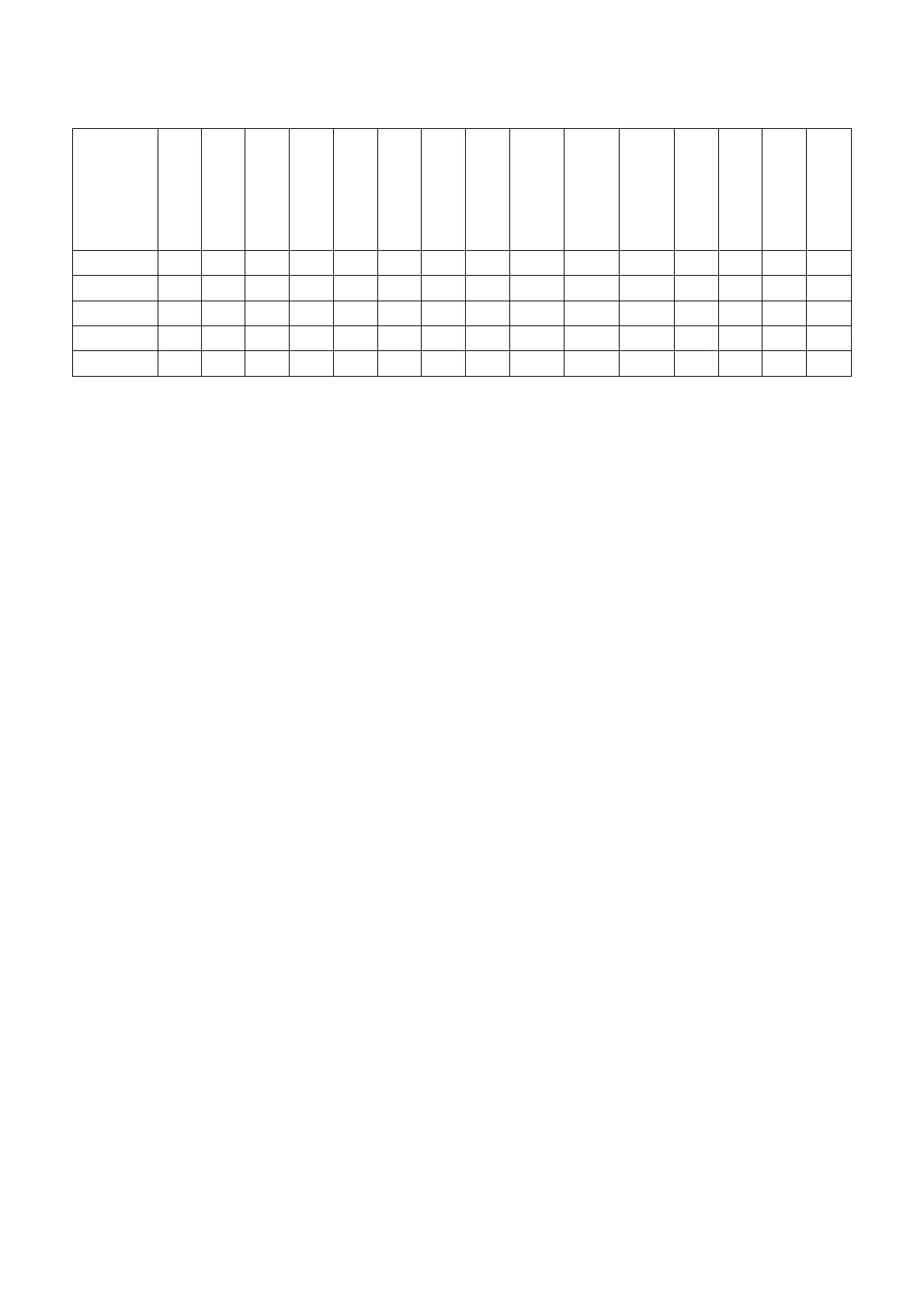

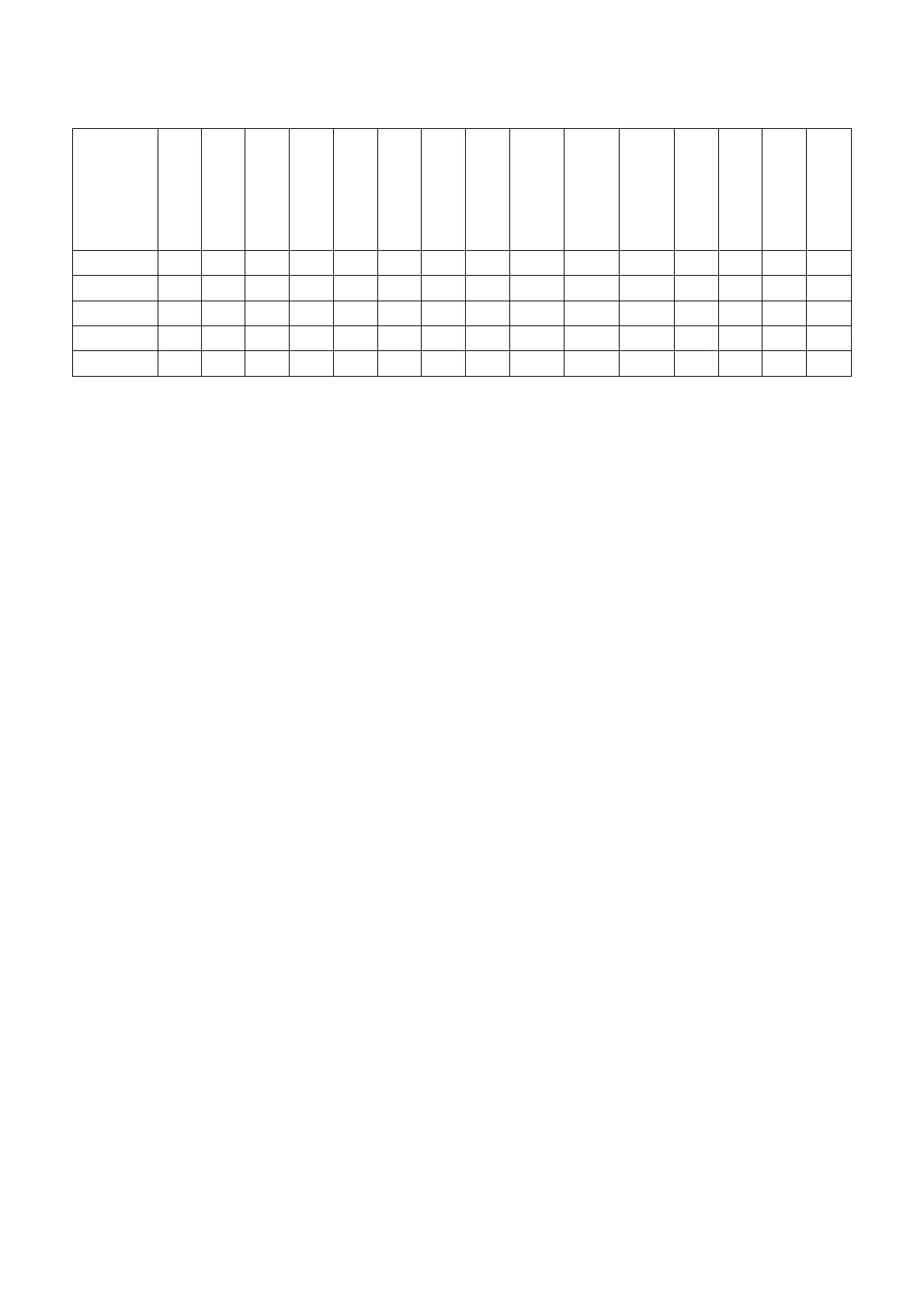

Table 2 Unit lifting weights and center of gravity dimensions

Model A (kg)

B

(kg)

D

E

(kg)

H (kg)

weight

(kg)

Ckt1

refrigera

kg)

Ckt2

refrigera

kg)

ting

weight

(kg)

Xcg

997 1123

- - - -

175 -

820 768

842

155 155

834 781

857

155 155

906 806

863

175 175

922 820

878

175 175

Neoprene Isolator Installation

Isolators are ready to install. Mountings have to be placed on a rigid and level foundation. External

equipment should not transmit additional vibration to the unit. The position of neoprene isolator and weight

per point are given in the handbook with the unit. Wrong placement along the unit may result in excessive

deflection.

1. Refer to Table 3 Isolator Selection, install the optional neoprene isolators at each mounting location as Figure

5 Isolator Placement. Isolators are identified by part number and color.

2. Secure the isolators to the mounting surface, using the mounting slots in the isolator base plate, as shown in

Figure 6 Neoprene Isolator. Do not fully tighten the isolator mounting bolts at this time.

3. Align the mounting holes in the base of the unit, with the threaded positioning pins on the top of the isolators.

4. Lower the unit on to the isolators and secure the isolator to the unit with a nut. Maximum isolator deflection

should be approximately 6mm.

5. Level the unit carefully. Fully tighten the isolator mounting bolts.

NOTICE - Guarantee Alignment and Spacing of Isolators!

For RTXC XE High Efficiency

RTXC310/330XE the isolator distance between master 200/220XE (W7/W8) and slave unit 110XE

(W5/W6) is 3042mm;

RTXC360XE the isolator distance between master 200XE (W7/W8) and slave unit 160XE (W7/W8) is

3462mm; RTXC400/440XE the isolator distance between master 200/220XE (W7/W8) and slave unit

200/220XE (W7/W8) is 3645mm;

Loading...

Loading...