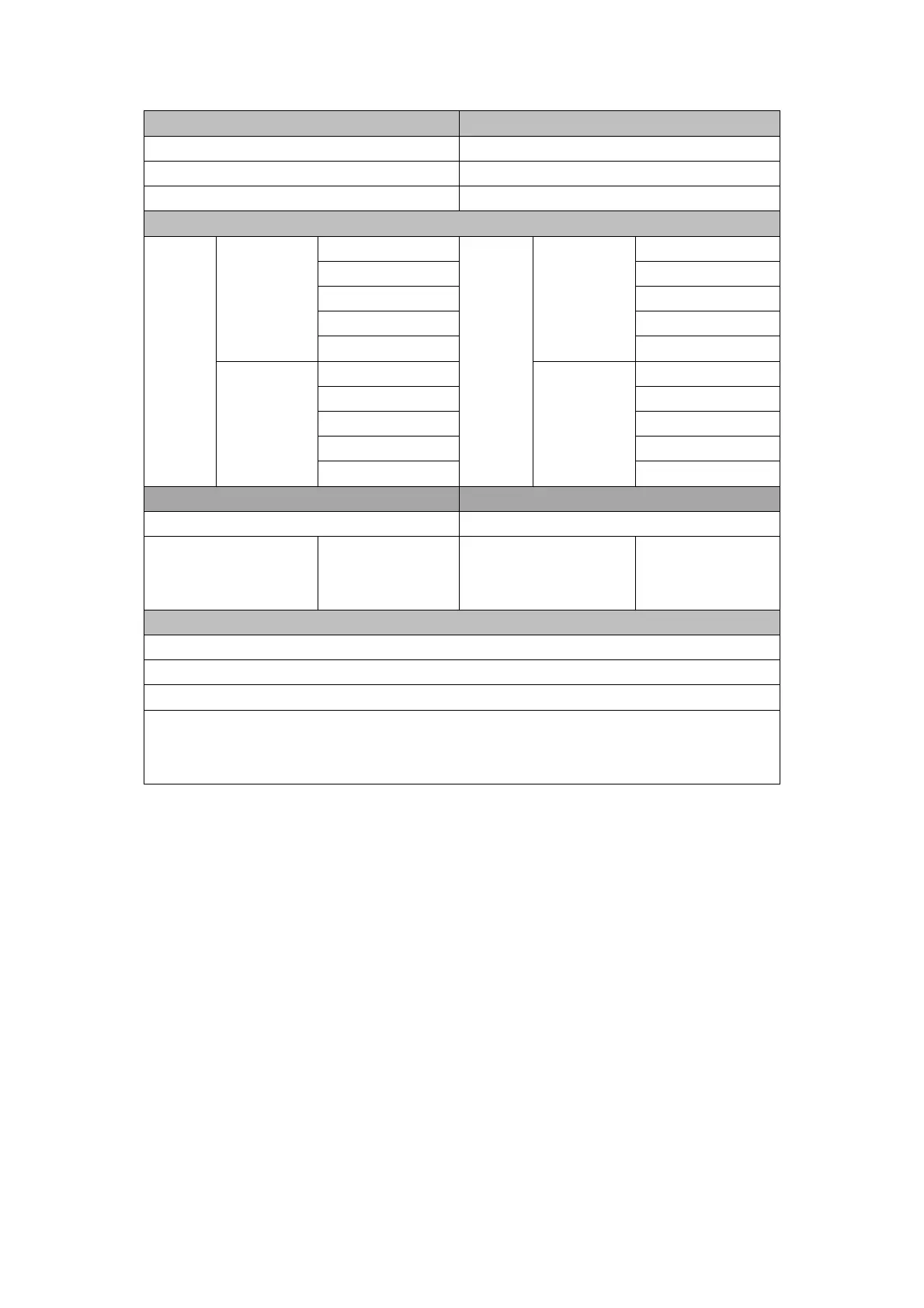

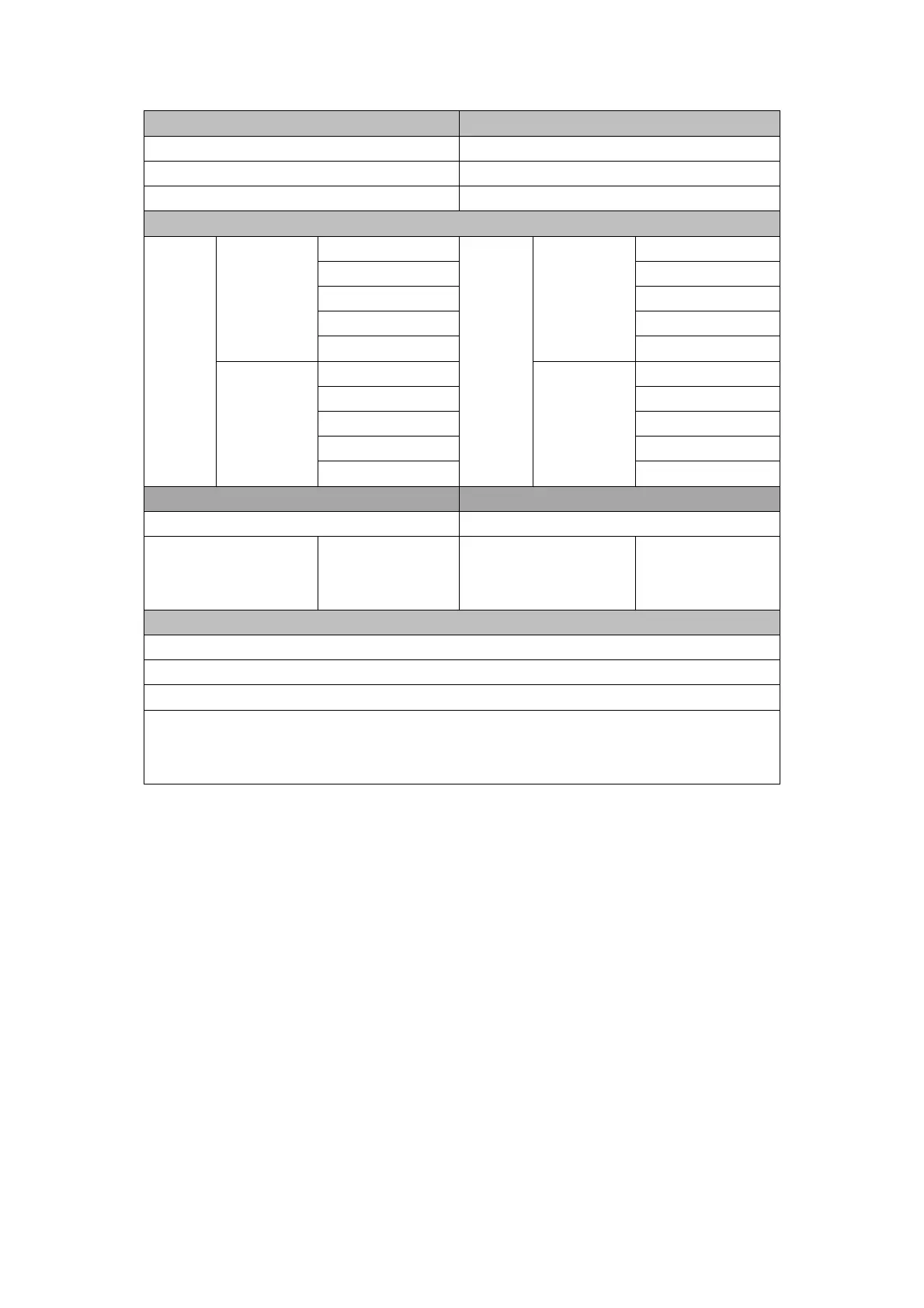

Unit Status (before Start-up)

Chiller appearance at arrival:

Pressure from TD7 (bar): ckt1: ckt2:

Phase Imbalance Rate (%):

R134a Charge (kg): ckt1: ckt2:

Circuit

1

Compressor

1A

Circuit

2

Compressor

2A

Compressor

1B

Compressor

2B

Evaporator Design Conditions

Evaporator Actual Conditions

(T):

Communications Interface Type:

Owner Witness Signature: ____________________________

Maintenance and Service

Refrigerant Field Charge Procedure

Once the system is deemed leak and moisture free, following the procedures to add refrigerant charge. Refer

to Figure 1 Unit Nameplate for refrigerant charge information.

1. Unit is empty of all refrigerant and under vacuum.

2. Attach charge hose to evaporator service valve and exclude the air in hose by refrigerant prior to open the

service valve.

3. Add charge to the evaporator according to the refrigerant type and amount indicated in the unit nameplate.

4. Close the service valve and remove the charge hose after charge.

CAUTION - Equipment Damage!

Constant water flow within allowed range through the evaporator is strictly necessary during the

whole charge process to prevent evaporator from freezing damage.

NOTICE - Equipment Damage!

Loading...

Loading...