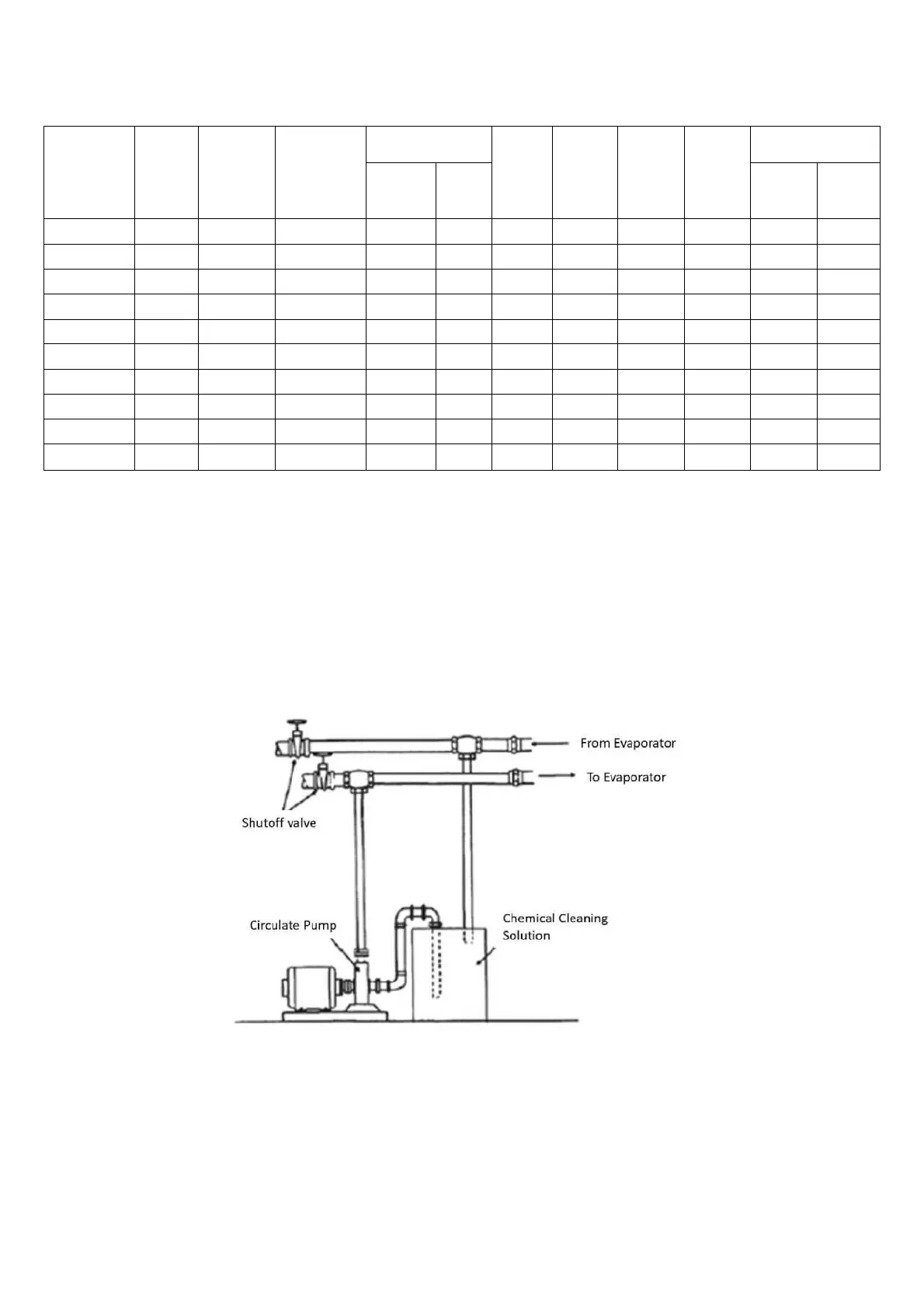

Table 8 Main components weights (kg)

Model

Compressor

Oil separator

Water side heat

exchanger

Air side heat exchanger

Fan

assembly

Reversing

valve

Receiver

Water box

Vertical Slab

Inlet water

side

Return

water side

692 86 707 183 187 54 25 79 185 35 19

692 86 910 160 164 54 22 79 191 41 15

692 86 910 160 164 54 22 79 191 41 15

692 86 1003 183 187 54 25 79 191 41 15

692 86 1003 183 187 54 25 79 191 41 15

692 86 707/1003 183 187 54 25 79

35/41 19/15

692 86 707/1003 183 187 54 25 79

35/41 19/15

692 86 910/1003 160/183 164/187 54 22/25 79 191 41 15

692 86 1003 183 187 54 25 79 191 41 15

692 86 1003 183 187 54 25 79 191 41 15

Note: all data is the weight of single component.

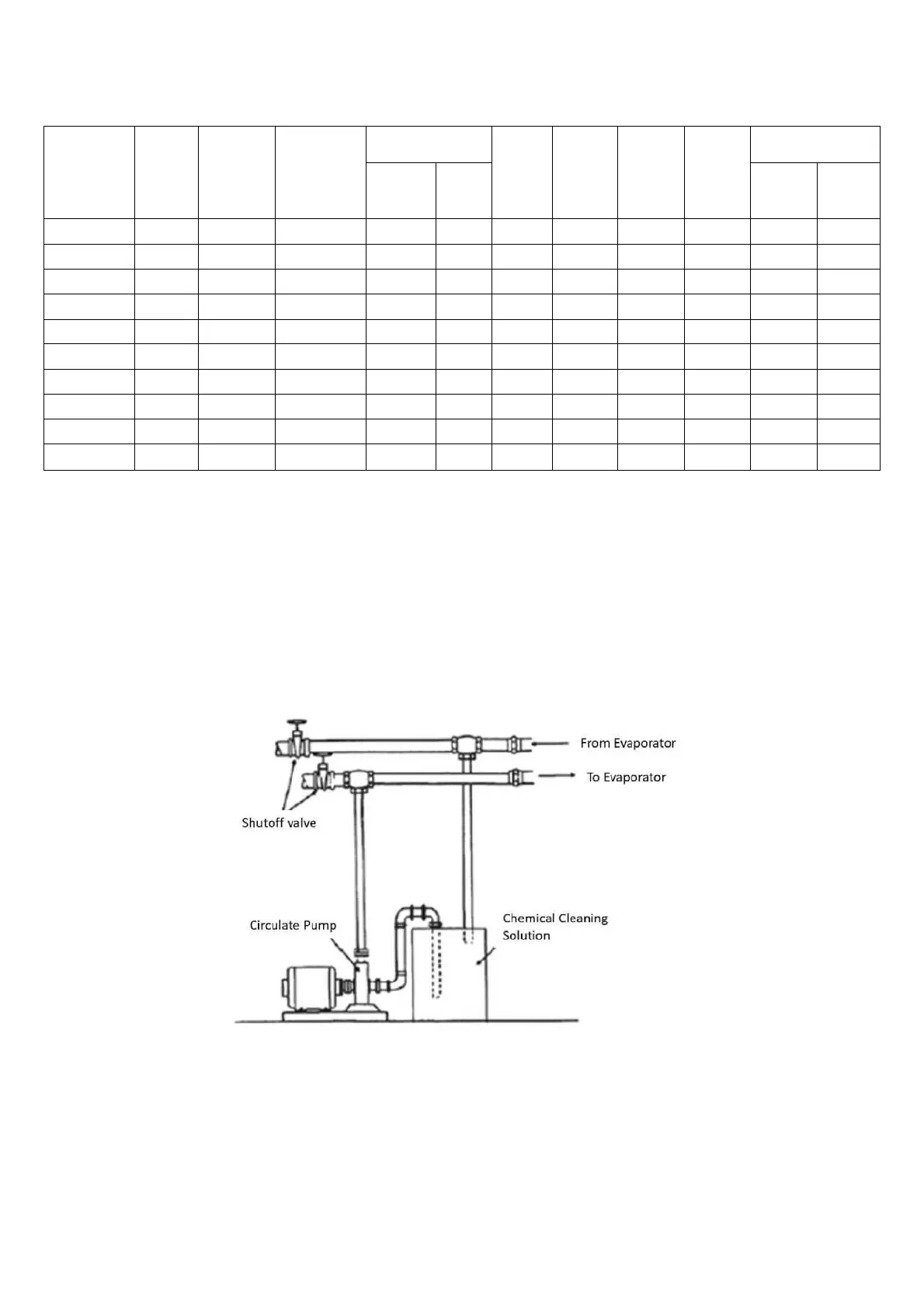

Chemical Cleaning Procedure

Scale deposits are best removed by chemical means. Consult qualified water treatment specialist for a

recommended cleaning solution. A standard chilled water circuit is composed solely of copper, cast iron and steel.

Improper chemical cleaning can damage tube walls. All of the materials used in the external circulation system,

the quantity of the solution, the duration of the cleaning period, and any required safety precautions should be

approved by the company furnishing the materials or performing the cleaning. Figure 20 shows the typical

backflushing unit of the evaporator.

Note: Chemical tube cleaning should always be followed by mechanical tube cleaning.

Figure 20 Chemical Cleaning

Loading...

Loading...