Do you have a question about the Trane S9V2B040U3PSBC and is the answer not in the manual?

Essential safety measures to follow during installation and servicing of the furnace.

General recommendations and requirements for furnace installation, codes, and site selection.

Specifies required clearances from combustible materials for furnace placement and operation.

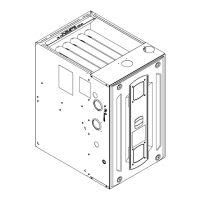

Dimensional outline drawing for the Upflow Furnace, B Size Cabinet.

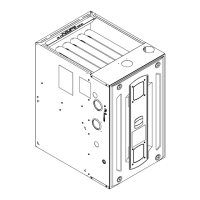

Dimensional outline drawing for the Downflow Furnace, B Size Cabinet.

Details on connecting the gas supply, including default configurations and important notes.

Procedure for checking gas flow rate and input rating of the furnace.

Steps for adjusting manifold pressure for proper gas valve operation.

Information on adjusting furnace input rate for installations at higher altitudes.

Specific requirements for using 3-inch vent piping, including offset couplings.

Recommended method for preventing condensation in combustion air piping.

Details on using an in-line trap kit for condensation management in venting.

Requirements for venting combustion air and exhaust for direct vent systems.

Requirements for venting combustion air and exhaust for non-direct vent systems.

Procedures for securely joining and sealing PVC, CPVC, and ABS vent pipes.

Requirements for using 3-inch vent piping in horizontal installations, including offset couplings.

Requirements for sealing vent holes through non-combustible walls.

Clearances required for non-direct vent terminations in Canada and the US.

Clearances required for direct vent terminations in Canada and the US.

Instructions for routing vent piping through existing chimneys.

Defines unconfined spaces and provides minimum area requirements for combustion air.

Defines confined spaces and details air supply requirements from inside or outdoors.

General rules for connecting return ductwork to the furnace, including limitations.

Installation of a coil on an upflow furnace, including duct connection details.

Installation of a coil with a downflow furnace, including duct connection details.

Connecting side return air for upflow furnaces, including transition requirements.

General guidance for installing return air filters externally for upflow furnaces.

Steps for preparing upflow furnaces for bottom and side return air filter installations.

Wiring diagrams for connecting thermostats and outdoor units to the furnace.

Instructions for installing condensate drains for upflow furnaces in vertical configurations.

Procedures for connecting condensate drains for downflow furnaces with left-side drainage.

Guidelines for installing condensate drains for furnaces in horizontal configurations.

Checklist of items to inspect before starting up the furnace.

Procedures for safely lighting the furnace and ensuring proper component operation.

Instructions for checking and adjusting limit switches for safe furnace operation.

Approved venting options for combustion air exhaust in upflow orientation.

Approved venting options for combustion air exhaust in horizontal left orientation.

Approved venting options for combustion air exhaust in downflow orientation.

Installing upflow furnace in upflow position with top vented combustion air.

List and explanation of status codes and error codes displayed by the IFC.

Steps for viewing, clearing, and resetting fault codes and factory defaults.

Procedure for entering and operating the furnace in Run Test Mode.

Examples of system status indicators and their meanings as displayed by the IFC.

Detailed sequence for 1st stage gas heating operation.

Detailed sequence for 2nd stage gas heating operation.

Sequence of operation for single stage cooling mode.

Sequence of operation for two stage cooling mode.

| Model Number | S9V2B040U3PSBC |

|---|---|

| Category | Furnace |

| Type | Gas |

| Efficiency Rating | High Efficiency |

| AFUE | 96% |

| Heating Capacity | 40, 000 BTU |

| BTU Input | 40, 000 BTU |

| Stages | 2-Stage |

| Blower Type | Variable Speed |

| Ignition Type | Hot Surface Ignition |

| Fuel Type | Natural Gas |

| Warranty | 10-Year Limited Warranty |

Loading...

Loading...