Installation

PART-SVN227B-EN 13

9. The wire harness for W63 through W66 is included

with the wiring kit along with the gender change wire

for units where an RTOM module was previously not

installed. Check the original Control Box Connections

diagram for how to use the gender change wire along

with the W63 through W66 harness to make the

connection from the RTOM J11 to Communications J2

pins. If the unit already had an RTOM and

Communications Module these wires will not be

needed.

Wiring Diagrams

Kit 018600350100 contains the wiring diagrams seen in

Table 7. The electrical and connection schematic diagrams

are common for all units but the electrical control and

power diagrams will need to be selected based on the unit

voltage and the type of heat that the unit has. Control

electrical, power electrical and schematic electrical

diagrams can be stuck over the existing electrical

diagrams on the inside of the control panel cover however

the schematic connection should not be placed over the

existing diagram as it only has wire labels for the wiring

that was changed or added during the conversion.

In addition to the wiring diagrams, affix

the top section of

the name

plate sticker that contains the upgrade order

number and serial number near the original unit

nameplate sticker.

Setting Economizer Damper

Positions

Note: New settings are needed for the economizer

damper position so that the amount of outdoor air

can keep up with the varying fan speed.

For units not configured with demand control ventilation

(DCV),

additio

nal minimum position setpoints to increase

outdoor airflow accuracy is supported; directions for

setting damper positions with DCV installed are included

in the DCV installation literature (ACC-SVN16*-EN). The

operation is similar to OA CFM Compensation on

Traditional VAV units, with the addition of a Design

Minimum Position setpoint at Middle Fan Speed

Command. The following setpoint potentiometers will be

used on the RTEM:

1. Design Min at Minimum Fan Speed Command (RTEM

DCV Min)

2. Design Min at Middle Fan Speed

Command (RTEM

DCV Setpoint LL)

3. Design Min at Full Fan Speed Command (RTEM Design

Min)

The contro

ller calculates the a

ctive

OA Damper Minimum

position between the user-selected setpoints based on the

supply fan speed command. By default, the Design

Minimum Position schedule is a linear line through all user

selectable Design Minimum Position setpoints. As with

Demand Controlled Ventilation, if the Design Minimum

Position at Middle fan speed command is set to a point that

would be higher than the calculated linear line between

the Design Minimum Position setpoints at Minimum and

Maximum fan speed command, the minimum position is

limited to the point that would make the Design Minimum

Position schedule linear.

Provisions have been made in Service Test Mode to allow

fo

r prope

r damper minimum position setup:

1. To set the Design Minimum Position setpoint at

M

inimum Fa

n Speed, set the unit to operate at Step 1

(Fan ON) or Step 2 (Economizer Open) and make the

proper adjustment.

2. To set the Design Minimum Position setpoint at Middle

F

an Spe

ed, set the unit to operate at Step 3 (Cool 1) and

make the proper adjustment.

3. To set the Design Minimum Position setpoint at Full

Fan Spe

ed, set the unit to operate at Step 4 (Cool 2) and

make the proper

adjustment.

Zone Sensor

For fully modulating Single Zone VAV operation, a zone

temperature sensor is required. A zone temperature

sensor does not ship with the upgrade kit. Wiring for the

zone temperature sensor is included with the sensor if

purchased separately.

If thermostat control is being replaced b

y the zone sen

sor

to achieve fully modulating single zone VAV operation, it is

possible to reuse the thermostat wires to connect in the

zone sensor. If the unit has been upgraded using the single

zone VAV parts and wiring method found in this manual,

no additional settings are needed for the unit perform as

a single zone VAV unit.

A thermostat will NOT provide fully modulating single

zone VAV contro

l. If the unit has been upgraded using the

single zone VAV parts and wiring but still has thermostat

control, the unit will revert to 2-speed fan control unless a

zone sensor is added.

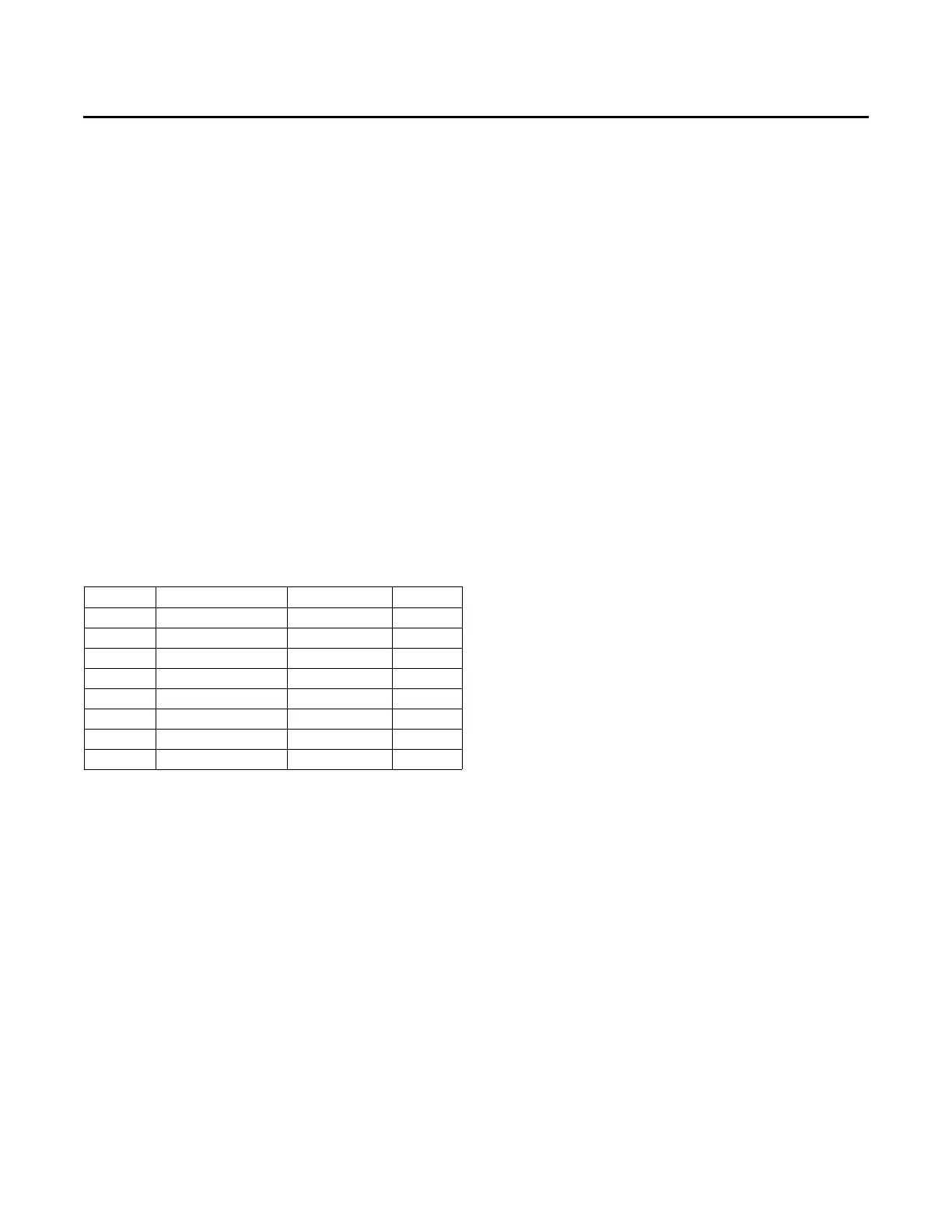

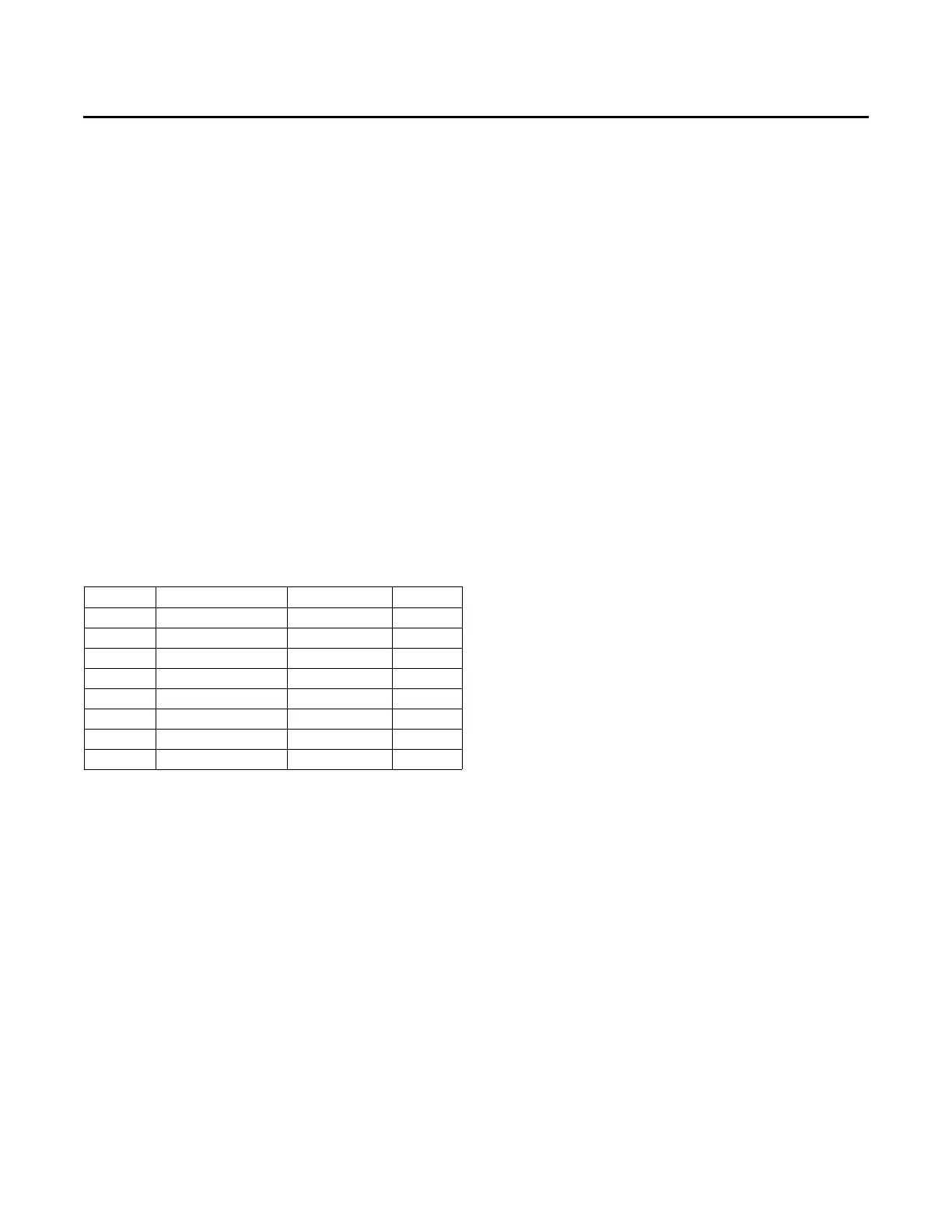

Table 7. Wiring diagrams

(a)

in kit 018600350100

(a) Always refer to the most recent revision of each wiring diagram.

Number Type Heat Voltage

23130064 Control Electrical Electric/None All

23130067 Control Electrical Gas All

23130053 Power Electrical Electric/None 208-230

23130054 Power Electrical Electric/None 460

23130345 Power Electrical Gas 208-230

23130347 Power Electrical Gas 460

23130376 Schematic Electrical All All

01860036 Schematic Connection All All

Loading...

Loading...