PART-SVN227B-EN 7

Installation

Inverter Duty Motor and Vibration

Reduction Bracket

1. Remove the supply fan drive belt.

2. Unbolt and remove the existing motor. Remove the

drive

sheave from the motor shaft.

Note: As the dr

ive sheav

e is a common component to

replace due to wear and a different sheave is not

needed when upgrading to SZVAV or Multispeed, a

new sheave is not included as part of the upgrade

program. Sheaves are available through Trane

Supply or your Trane or American Standard parts

distributor.

3. Affix the sheave to the shaft

of the inverter duty motor.

A new shaft key is provided with the inverter duty

motor.

4. A new wiring harness to connect the motor to the VFD

is provided and will need

to be connected to the motor.

The gauge of the wire in the motor to drive harness

might be smaller than the wires that the existing motor

was using, this is in line with the current production

design.

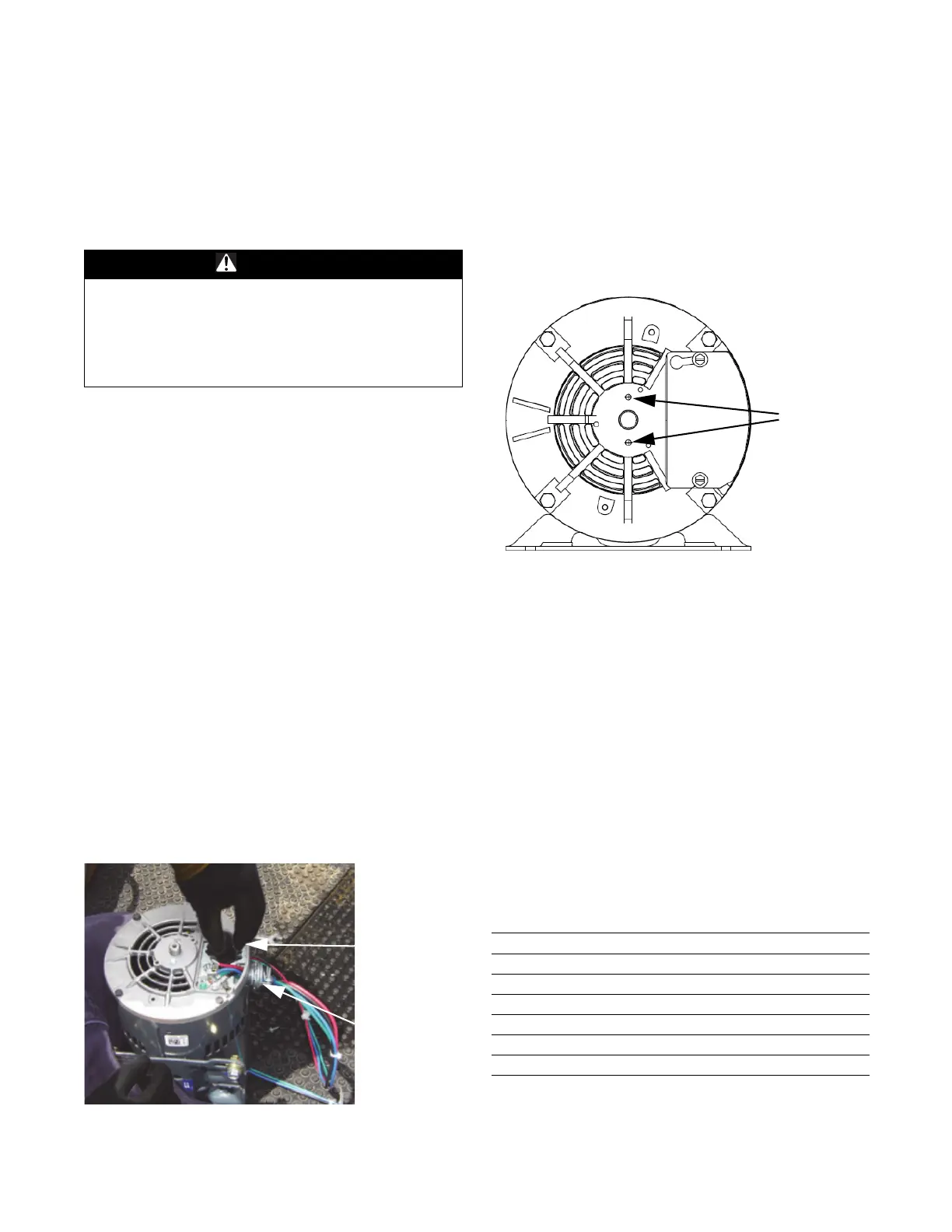

Note: The m

otors used in the upgrade are dual voltage. If

the unit that is being upgraded is not 460V the

voltage plug on the back of the motor will need to

be taken out, rotated 180° and reinserted.

5. For additional motor bearing protection, a motor shaft

grounding ring is provided. Before installing the

motor, follow a, b, and c below to install the grounding

ring.

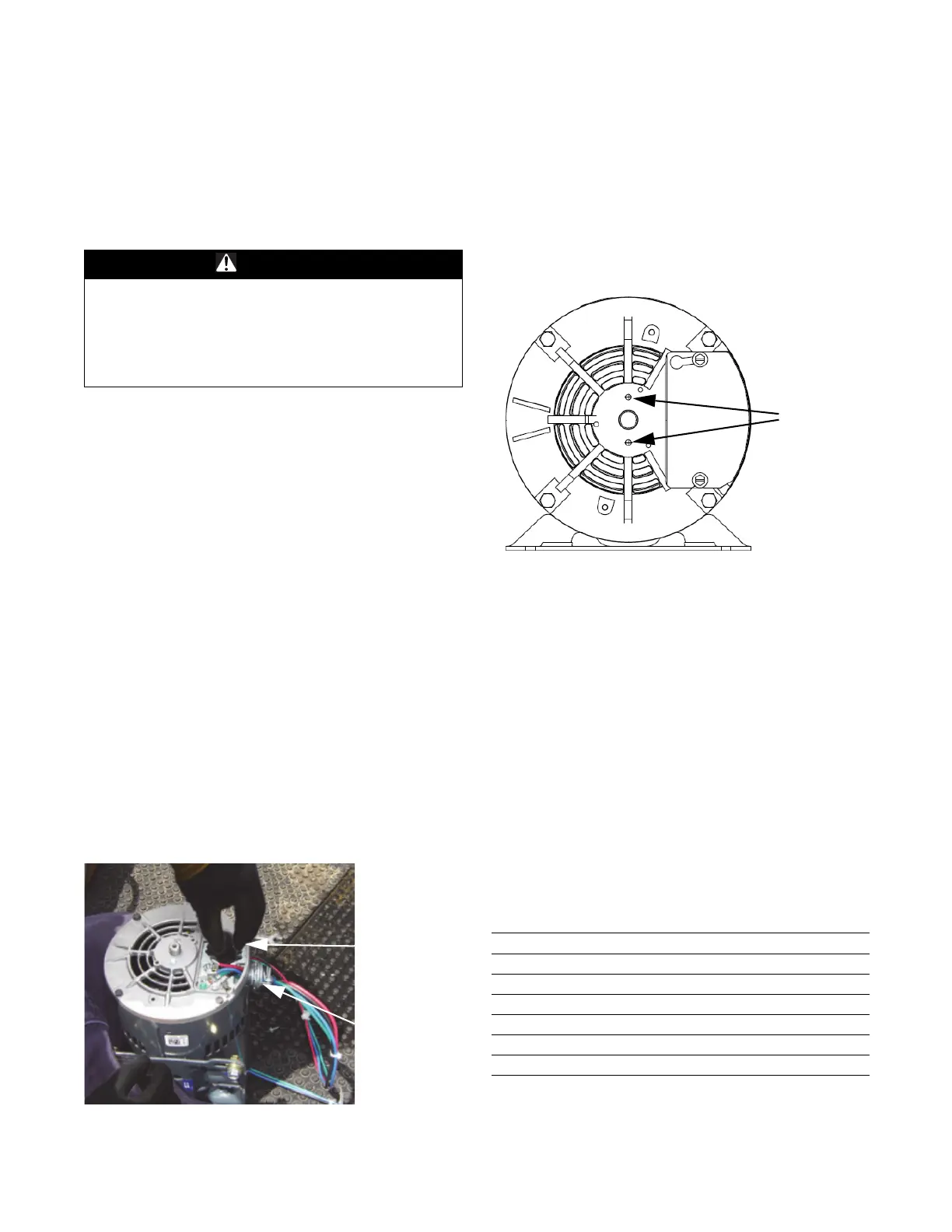

a. Remove the two screws from th

e back of the motor

as shown in Figure 2.

b. Slide the grounding ring over the end of the shaft

an

d ali

gn the holes in the ring with the holes that the

screws were in.

c. Using the screws and washers provided wi

th the

grounding ring secure the ring to the motor.

6. Install the inverter duty motor into

the unit.

7. Determine the location of the holes used to hold the

vibration bracket onto the motor mounting panel.

a. Dry fit the bracket according to Figure 3.

b. Use a marker to mark the lo

cation to

drill the holes

for the screws that will hold the bracket to the motor

mounting panel.

8. Drill the holes that were marked

using the 1/

8 inch drill

bit provided.

9. Install the vibration dampening bracket. See Fi

gure 3

for details.

WARNING

Hazardous Voltage!

Failure to disconnect power before servicing could

result in death or serious injury. Disconnect all electric

power, including remote disconnects before servicing.

Follow proper lockout/tagout procedures to ensure the

power can not be inadvertently energized.

Figure 1. Inverter duty motor

Voltage Plug

Reuse wire

collar from

motor that

was removed

Figure 2. Back side of inverter duty motor

Table 3.

Balloon Part

1 Inverter Duty Motor

2 Vibration Reduction Bracket

3 Screw, 1/4-14 X 0.625 (X25240209030)

4

(a)

(a) The torque applied to the nuts on the end of the extended bolts is to

be as follows:

18–25 in·lb (~2 ft·lb) for 3 and 5 HP motors

Nut, 10-32 Hex Lock (X28022600000)

5

(b)

(b)Use 1 washer on each bolt for 3 and 5 HP motors.

Washer, 0.328 ID X 2.00 OD (X22050242010)

6 Nut (attached by motor supplier)

Loading...

Loading...