30 CNT-SVX17G-EN

Sequence of Operations

The auto-commissioning test does not require a flow sensor or an auxiliary temperature

sensor. If there is no flow sensor, the controller runs in pressure-dependent mode. An

auxiliary temperature sensor in the discharge air stream is required for testing of the fan

and the reheat. The fan and the reheat are not tested if the discharge air temperature

sensor is not present. The fan is not tested if there is no fan. Local reheat is tested, if it

is present. Remote reheat is not tested.

The sequence starts on receipt of an auto-commission command from the Tracer

Summit

™ BAS or the Rover™ service tool. The auto-commission command contains a

time/date stamp. No third party tool can start the auto-commissioning sequence. The

user then chooses to commission all VAV boxes or one VAV box.

The results of auto-commissioning are contained in a structured network variable called

rep

orted auto commissioning report. The controller places the time/date stamp in the

report. The structure is loaded with the default values for all of the fields when the auto-

commissioning test sequence starts. The the fields are updated with the results as the

sequence progresses. The data is held until the next auto-commissioning test.

If an auto-commission command is received in the middle of an auto-commissioning

cy

cle the auto-commissioning sequence restarts. If an auto-commission command is

received during calibration, calibration aborts and restarts after auto-commissioning

finishes. If an abort auto-commission command is received during the calibration portion

of the primary air valve test, it is honored after the air valve calibration finishes.

The mode field of reported unit status reports TE

ST when the controller is in the auto-

commissioning sequence.

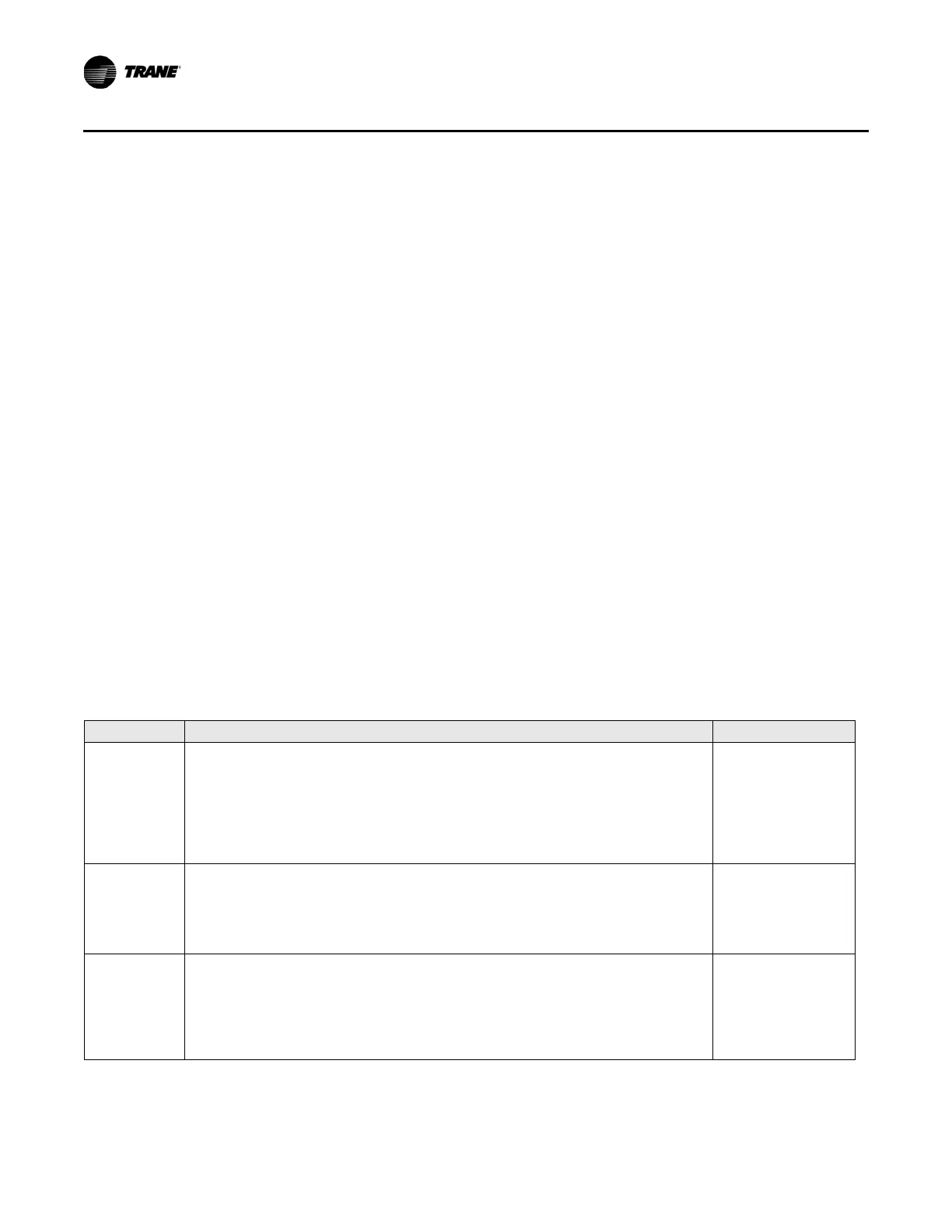

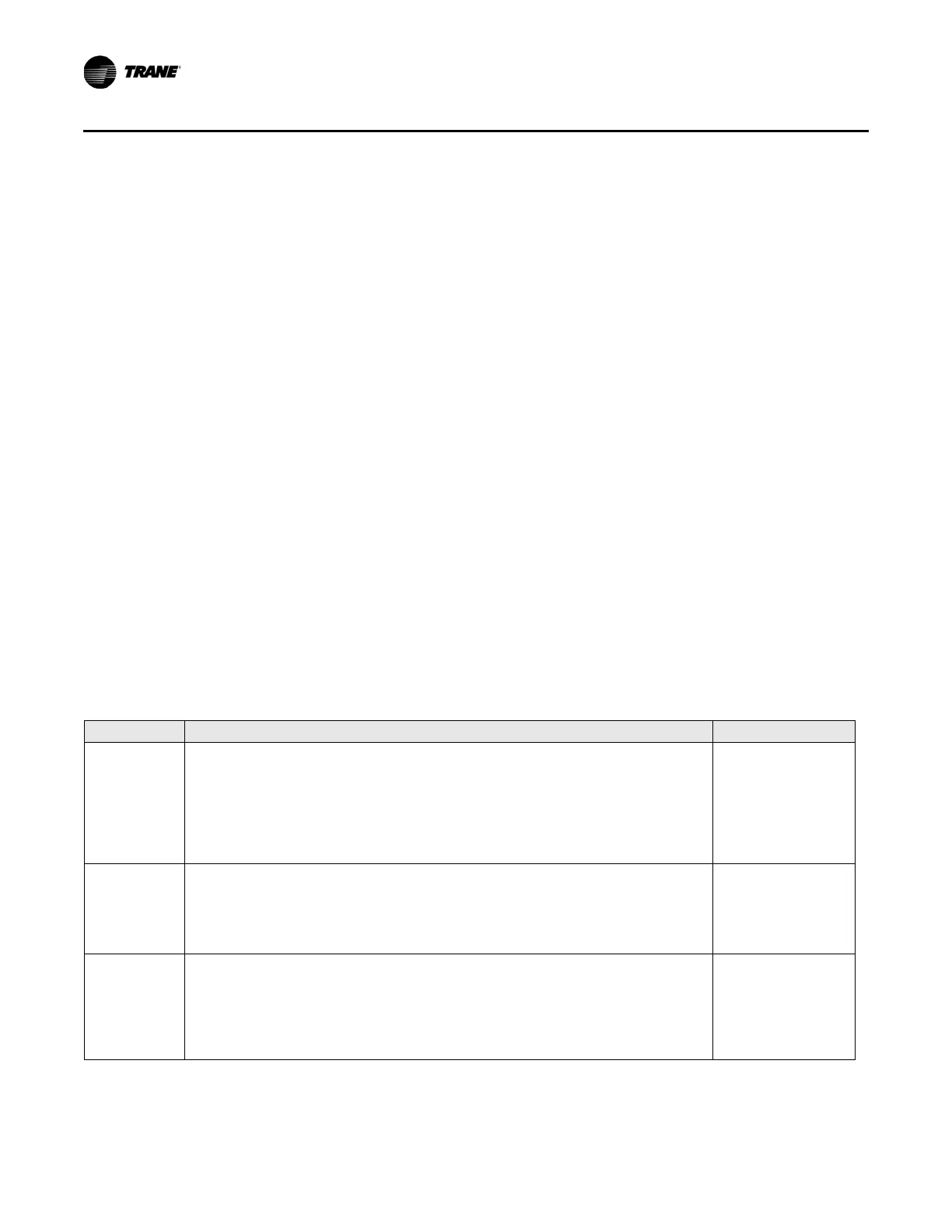

Table 20.Auto-commissioning test sequence

Item Test action Reported data

Primary air

va

lve and

airflow

a

1. Turn Off fan and reheat.

2. Close air valve and modulating water valve (if present).

3. Calibrate the airflow sensor.

4. Open the air valve to 40% of the configured maximum airflow. Record the position

o

f the air valve.

5. Open the air valve to 100% of the configured maximum airflo

w. Record the position

of the air valve.

Primary air valve

p

osition at 40% and

100% flow

Fan flow

b

1. Record the auxiliary temperature at the configured maximum airflow.

2. Close the primary air valve.

3. Turn On the fan (if present).

4. Monitor auxiliary temperature for 3 minutes or until it changes by 10°F.

5. Record the auxiliary temperature.

Starting and ending

auxiliary

temperature

Local reheat

hyd

ronic

b

1. If no fan is present, open the air valve to the configured minimum local heating

airflow.

2. If the fan is present, close the air valve and turn On the fan.

3. Record the auxiliary temperature.

4. Open the water valve to 100% open.

5. Monitor the auxiliary temperature for 10 minutes or until it changes by 10°F.

Starting and ending

auxiliary

te

mperature

Loading...

Loading...