CNT-SVX17G-EN 85

Troubleshooting

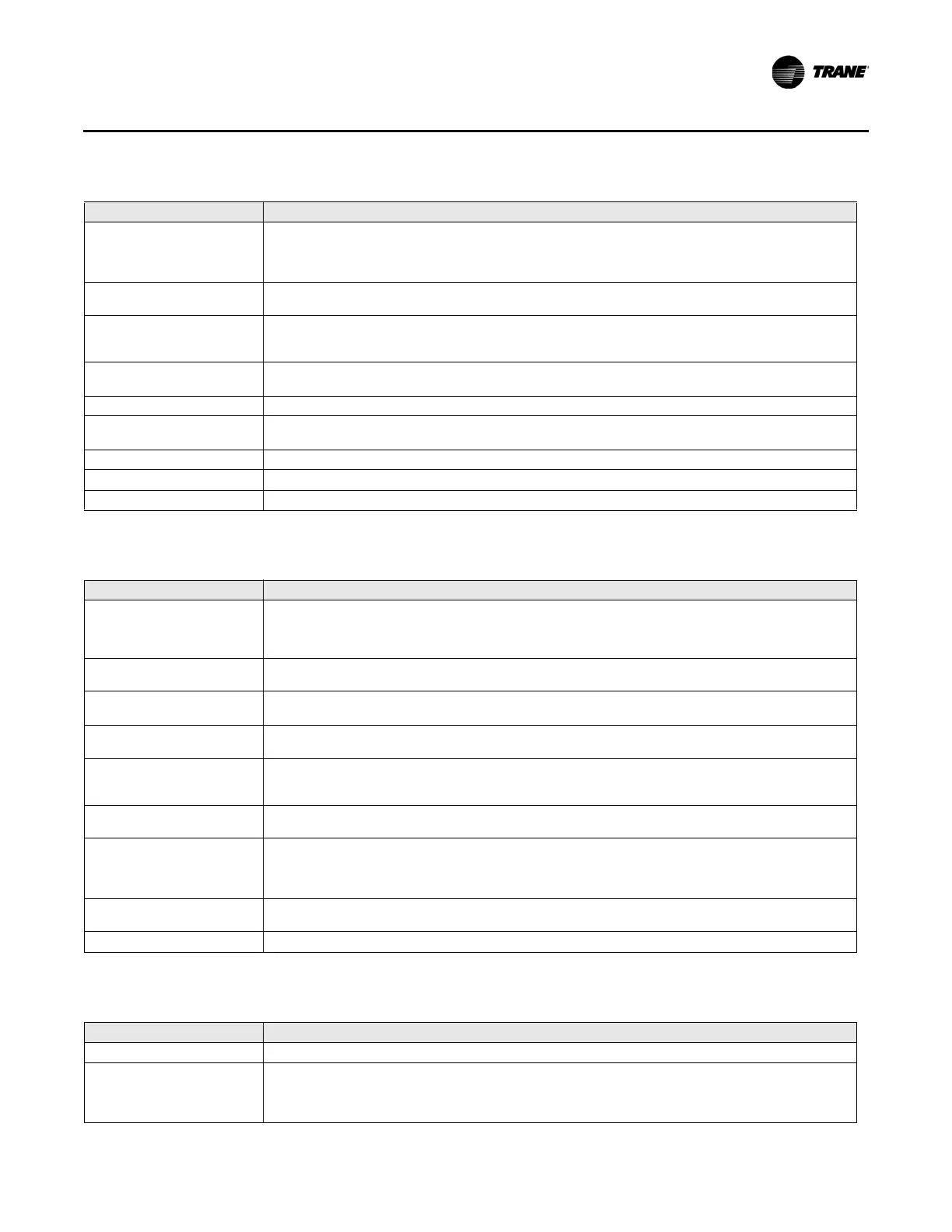

Manual output test

The controller includes a manual output test function you can use to verify output operation and associated

output wiring. However, based on the current step in the test sequence, the unit reheat may not be on. For

more information on manual output test, refer to sections “Manual Output Test,” p. 80 and “Manual Output

Tes t ,” p. 28.

Unit wiring

The wiring between the controller outputs and the fan relays and contacts must be present and correct for

no

rmal re

heat operation.

Low primary airflow

The unit must have sufficient primary airflow to energize t

h

e local electric reheat outputs. If the airflow never

reaches this level or falls below this level, the reheat is not energized. For more information on reheat

control, refer to “Reheat Control,” p. 45.

Primary air temperature

abo

ve reheat enable setpoint

The primary air temperature must be below the reheat enable setpoint before the reheat can be energized.

This prevents damage to the reheat coils due to excessive heat.

Invalid reheat enable setpoint Invalid reheat enable setpoint disa

bles local electric heat.

Invalid primary air

temperatur

e

Disables local electric heat when the system mode is heat or if system mode is auto with warm default

primary air temperature.

Fan override active Fan override Off with a fan present disables local electric reheat.

Auxiliary heat enable Communicated auxiliary heat enable is limiting reheat unit

capacity or disabling reheat completely.

Water valve override Water valve override, when in effect, controls outputs.

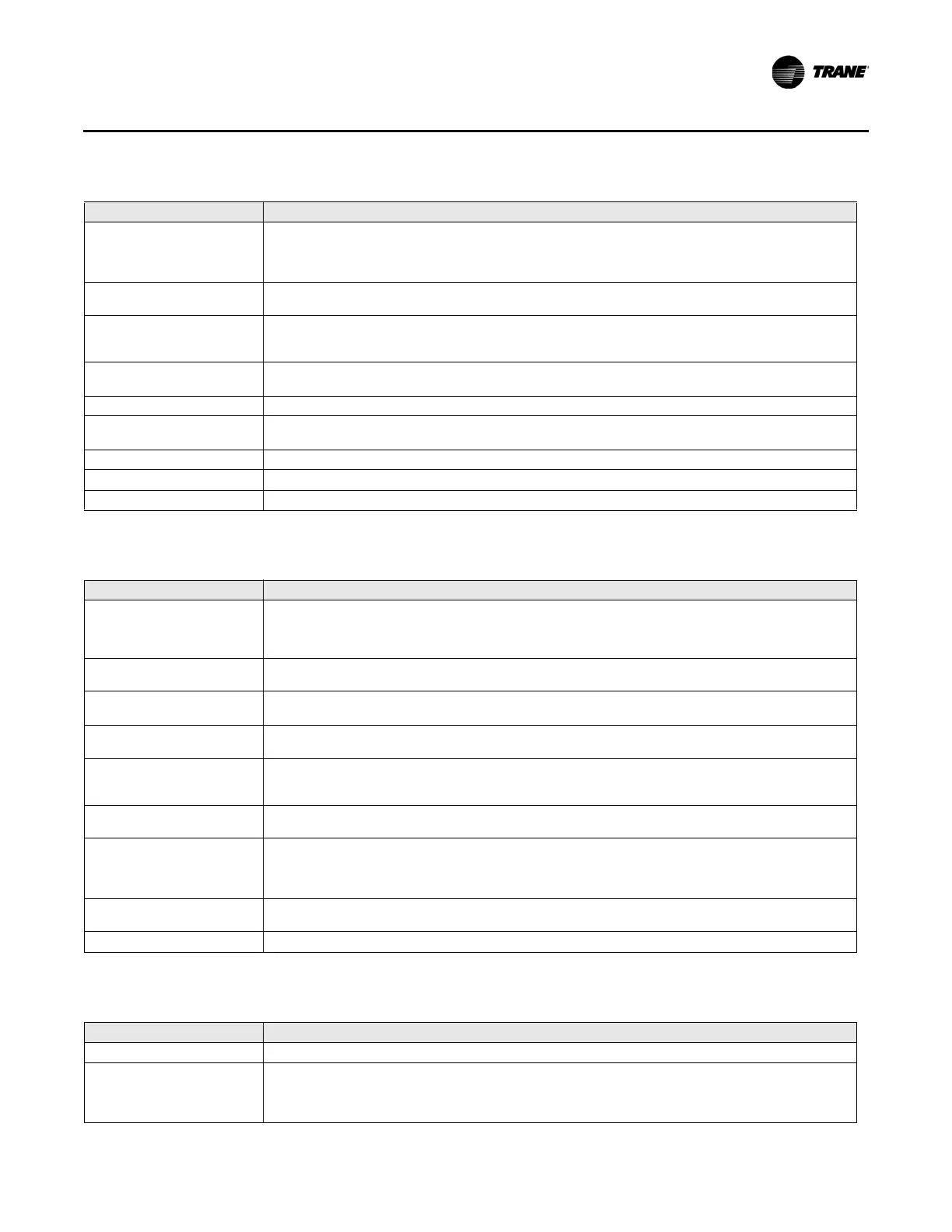

Table 57. Fan output does not energize

Probable cause Explanation

Power-up control wait

When power-up control wait is enabled (non-zero time), the controller remains Off until one of two

condi

tions occurs:

• The controller exits power-up control wait once it receives communicated information.

• The controller exits power-up control wait once the power-up control wait time expires.

Unoccupied operation

When the controller is in the

unoccupied mode, the fan is cycled between On and Off with capacity to

maintain zone temperature control.

Requested mode Off

You can communicate a desired operating mode (such as Off, heat, and cool) to the controller. When Off

is communi

cated to the controller, the unit controls the fan Off. There is no heating or cooling.

Diagnostic present

A specific list of diagnostics affects fan operation. For more information on controller diagnostics, refer to

Table 50, p. 81.

No power to the controller

If the controller does not have power, the unit fan does not operate. For the controller to operate normally,

it

must have an input voltage of 24 Vac. When the green LED is Off continuously, the controller does not

have sufficient power or has failed. For more information on green LED, refer to “Green Status LED,” p. 80.

Unit configuration

The controller must be properly configured based on the actual installed end devices and application. When

the un

it configuration does not match the actual end devices, the fan may not work correctly.

Manual output test

The controller includes a manual output test function you can use to verify output operation and associated

ou

tpu

t wiring. However, based on the current step in the test sequence, the unit fan may not be On. For

more information on manual output test, refer to sections “Manual Output Test,” p. 80 and “Manual Output

Tes t ,” p. 28.

Unit wiring

The wiring between the controller outputs and the fan relays and contacts must be present and correct for

normal fan op

eration.

Fan override Fan is overridden via communicated fan speed command.

Table 56. Reheat outputs do not energize (continued)

Probable cause Explanation

Table 58. Air valve and/or water valve stay open

Probable cause Explanation

Normal operation The controller opens and closes the valves to meet the unit capacity requirements.

Manual output test

The controller includes a manual output test function you can use to verify output operation and associated

ou

tpu

t wiring. However, based on the current step in the test sequence, the valve(s) may be open. For more

information on manual output test, refer to sections “Manual Output Test,” p. 80 and “Manual Output Test,”

p. 28.

Loading...

Loading...