Installation

20 RT-SVX37B-EN

General Unit Requirements

The checklist listed below is a summary of the steps

required to successfully install a commercial unit. This

checklist is intended to acquaint the installing personnel

with what is required in the installation process. It does not

replace the detailed instructions called out in the

applicable sections of this manual.

• Check the unit for shipping damage and material

shortage; file a freight claim and notify appropriate

sales representative.

• Verify correct model, options and voltage from unit

nameplate.

• Verify that the installation location of the unit will

provide the required clearance for proper operation.

• Assemble and install the roof curb (if applicable). Refer

to the latest edition of the curb installers guide that

ships with each curb kit.

• Fabricate and install ductwork; secure ductwork to

curb.

• Install pitch pocket for power supply through building

roof. (If applicable)

• Rigging the unit.

• Set the unit onto the curb; check for levelness.

• Ensure unit-to-curb seal is tight and without buckles or

cracks.

• Install and connect a condensate drain line to the

evaporator drain connection.

Note: Condensate Overflow Switch (if equipped) will not

work if unit is not level properly.

Factory Installed Economizer

• Ensure the economizer has been pulled out into the

operating position. Refer to the economizer installers

guide for proper position and setup.

• Install all access panels.

Horizontal Discharge

Conversion (5 Ton Unit)

Supplies Needed by Installer for Conversion: 3 oz. tube of

High Temperature RTV sealant. (500°F / 260°C: Similar to

Dow Corning 736)

Note: Failure to use recommended sealant could result in

unit performance loss.

If a unit is to be converted to a Horizontal discharge, the

following conversion must be performed:

1. Remove RETURN and SUPPLY duct covers.

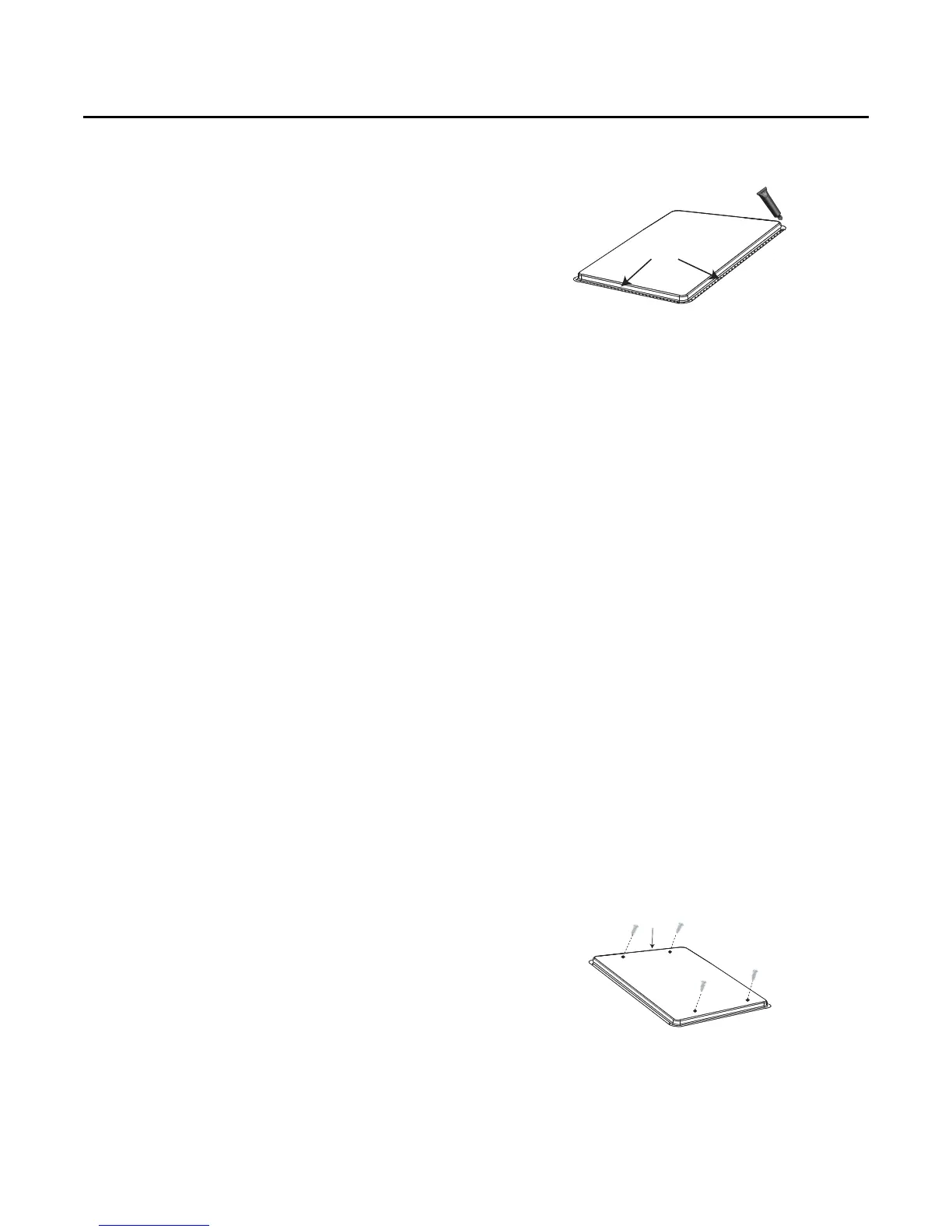

2. Locate supply cover. Apply ¼ in. (6mm.) continuous

bead of 500°F RTV sealant to the flange as shown.

3. Position duct cover as shown, rotate 90 degrees to

allow entrance into supply opening.

4. Slide duct covers into duct openings until inward edge

of duct cover engages with the 2 retaining clips on the

duct flanges. Secure the outward edge of each duct

cover with 2 screws.

5. Slide RETURN DUCT COVER (insulation side up) into

supply opening until inward edge of duct cover

engages with the 2 retaining clips on the duct flange.

Secure outward edge of the duct cover with two

screws.

Horizontal Discharge Conversion

(6 Through 10 Ton Units)

Supplies Needed by Installer for Conversion: 3 oz. tube of

high Temperature RTV sealant. (500°F / 260°C: Similar to

Dow Corning 736)

Note: Failure to use recommended sealant could result in

unit performance loss.

If a unit is to be converted to a Horizontal discharge, the

following conversion must be performed:

1. Remove RETURN and SUPPLY duct covers.

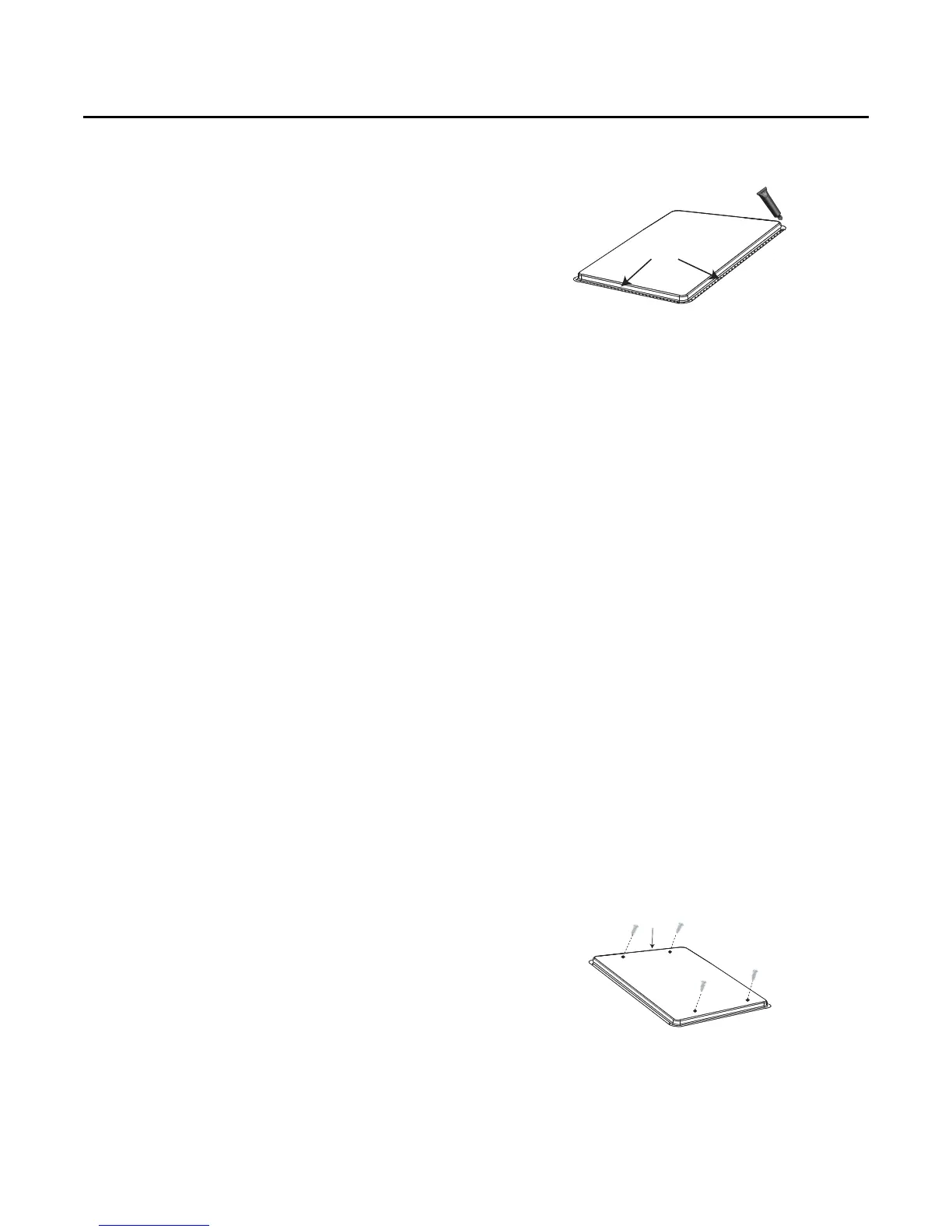

2. Place SUPPLY DUCT COVER over down-flow return

opening. (insulation side down)

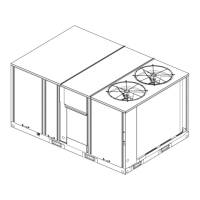

3. Using self-drilling screws, (or screws removed from

duct cover), screw through dimples to attach DUCT

COVER to base.

4. On original RETURN DUCT COVER, apply ¼”(6mm.)

continuous bead of 500°F RTV sealant around flange

(opposite insulation side), as shown.

Figure 18.

Figure 19.

Supply Duct Cover

Screw into 4

dimples on top

edge

Loading...

Loading...