I STALLER'S GUIDE

@

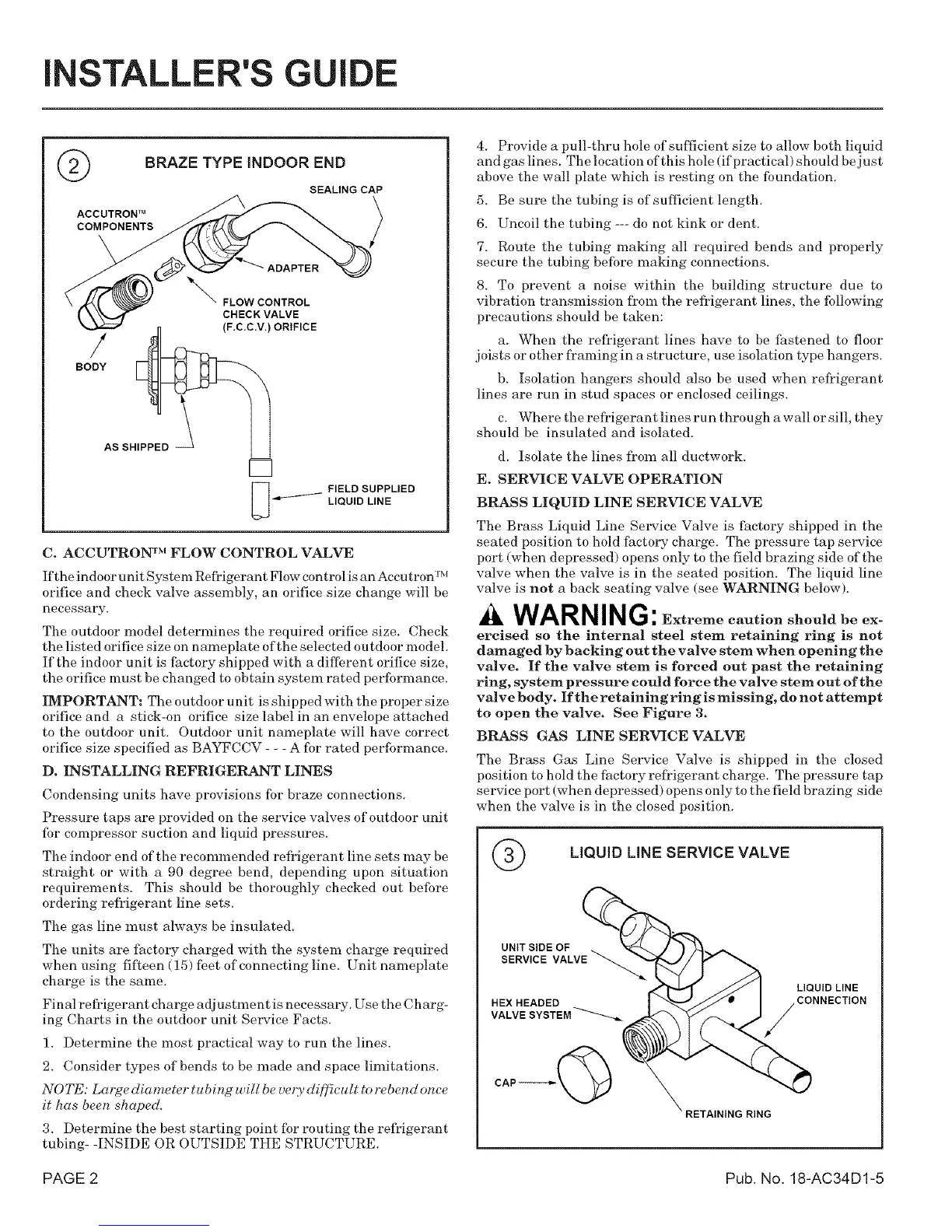

BRAZE TYPE iNDOOR END

SEALING CAP

ACCUTRON TM

COMPONENTS

/

BODY

_'_ FLOW CONTROL

CHECK VALVE

(F.C.C.V.) ORIFICE

AS SHIPPED -_

FIELD SUPPLIED

LIQUID LINE

C. ACCUTRON TM FLOW CONTROL VALVE

c_ IM

If the indoor unit Syste In Refi'i_ erant F1ow control is an Accu tron-

orifice and check valve assembly, an orifice size change will be

necessary.

The outdoor model determines the required orifice size. Check

the listed orifice size on nameplate of the selected outdoor model.

If the indoor u nit is factory shipped with a dilIbrent orifice size,

the orifice must be changed to obtain system rated performance.

IMPORTANT: The outdoor u nit is shipped with the proper size

orifice and a stick-on orifice size label in an envelope attached

to the outdoor unit. Outdoor unit nameplate will have correct

orifice size specified as BAYFCCV - - - A fbr rated performance.

D. INSTALLING REFRIGERANT LINES

Condensing units have provisions for braze connections.

Pressure taps are provided on the service valves of outdoor unit

fbr compressor suction and liquid pressures.

The indoor end of the recommended refrigerant line sets may be

straight or with a 90 degree bend, depending upon situation

requirements. This should be thoroughly checked out before

ordering refl'igerant line sets.

The gas line must always be insulated.

The units are factory charged with the system charge required

when using fif_een (15) feet of connecting line. Unit nameplate

charge is the same.

Final refrigerant charge adjustment is necessary. Use the Charg-

ing (?harts in the outdoor unit Service Facts.

1. Determine the most practical way to run the lines.

2. Consider types of bends to be made and space limitations.

NOTE: Large diameter tubing will be very di[f_cult to rebend once

it has been shaped.

3. Determine the best starting point fbr routing the refl_igerant

tubing- -INSIDE OR OUTSIDE THE STRUCTURE.

4. Provide a pull-thru hole of suflicient size to allow both liquid

and gas lines. The location of this hole (if practical) should be just

above the wall plate which is resting on the foundation.

5. Be sure the tubing is of sufficient length.

6. Uncoil the tubing --- do not kink or dent.

7. Route the tubing maMng all required bends and properly

secure the tubing before making connections.

8. To prevent a noise within the building structure due to

vibration transmission fl_oln the refrigerant lines, the following

precautions should be taken:

a. When the refl'igerant lines have to be fastened to floor

joists or other fl'aming in a structure, use isolation type hangers.

b. Isolation hangers should also be used when refrigerant

lines are run in stud spaces or enclosed ceilings.

c. Where the refrigerant lines ru n through a wall or sill, they

should be insulated and isolated.

d. Isolate the lines fl'om all ductwork.

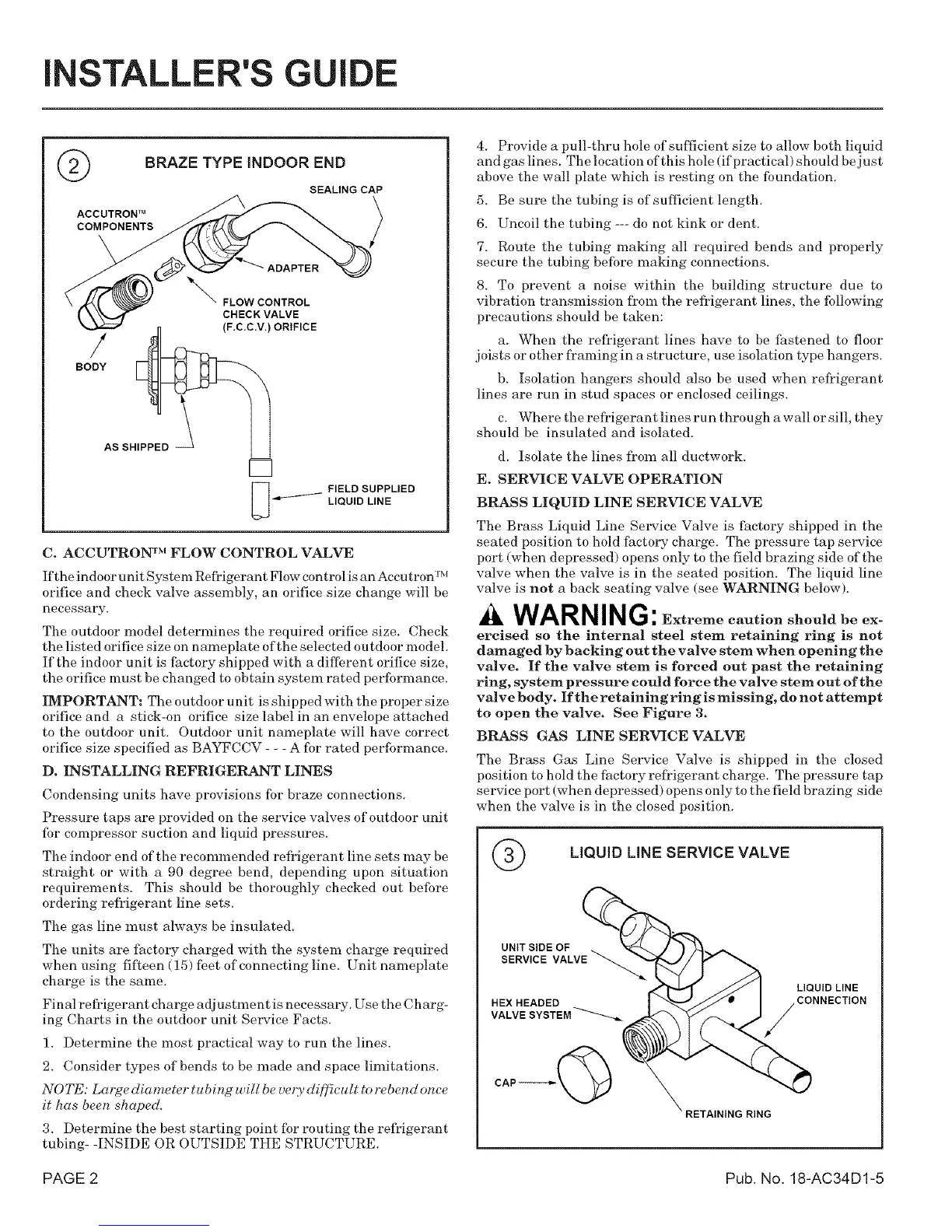

E. SERVICE VALVE OPERATION

BRASS LIQUID LINE SERVICE VALVE

The Brass Liquid Line Service Valve is factory shipped in the

seated position to hold factory charge. The pressure tap service

port (when depressed) opens only to the field brazing side of the

valve when the valve is in the seated position. The liquid line

valve is not a back seating valve (see WARNING below).

WARNING: Extremecautionshouldbeex-

ercisedso the internal steel stem retaining ring is not

damaged by backing out the valve stem when opening the

valve. If the valve stem is forced out past the retaining

ring, system pressure could force the valve stem out of the

valve body. If the retaining ring is missing, do not attempt

to open the valve. See Figure 3.

BRASS GAS LINE SERVICE VALVE

The Brass Gas Line Service Valve is shipped in the closed

position to hold the factory refl'igerant charge. The pressure tap

service port (when depressed) opens only to the field brazing side

when the valve is in the closed position.

LIQUID LiNE SERVICE VALVE

UNIT SIDE OF

SERVICE VALVE

HEX HEADED

CAP-----_

LIQUID LINE

CONNECTION

RING

PAGE 2 Pub. No. 18-AC34D1-5

Loading...

Loading...