-10-

EN - KWJ700/900

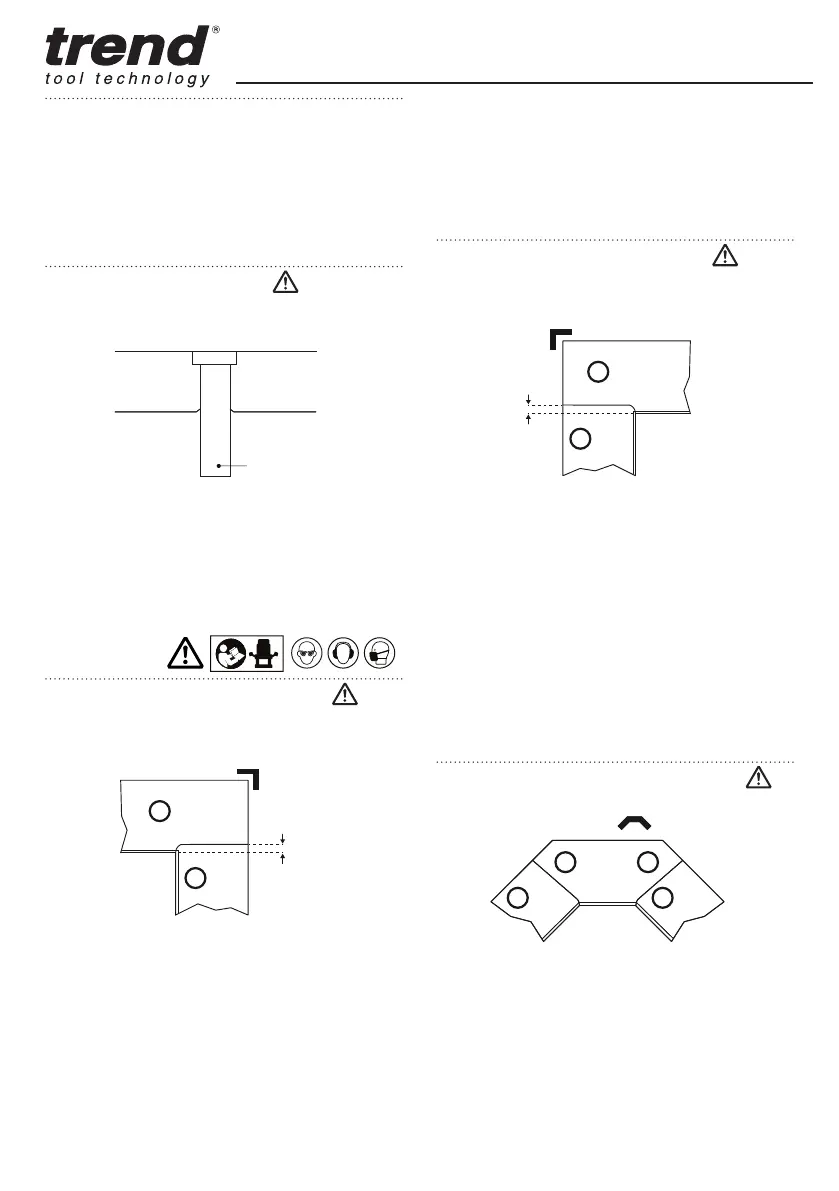

Setting out the Joints

When cutting a joint ensure location pins contact the

postformed edge of the worktop. For certain joints the

worktop will need to be inverted so that all cuts are

made into the postformed edge, never out through

it. When routing worktop the balancing paper on the

underside may feather edge – this feather edge should

be removed with abrasive paper.

Location Pin Identification

Up to 6 location pins are used in different holes in the jig

to align the correct template aperture for the application.

F90 - Female joint, 35mm inset

M90 - Male joint, 35mm inset

M45 - Male joint, 45°/hob joint

F45 - Female joint, 45°/hob joint

B - Connector Bolt Recess

Location pins are tapered to ensure a good tight fit in hole.

OPERATION

90

O

Right Hand Joint - (Fig.2a-3d)

2a) Setting up for Right Hand 90

O

Female Joint.

2b) Routing roughing cuts x 5 for Right Hand 90

O

Female

Joint.

2c) Routing finishing cut for Right Hand 90

O

Female

Joint.

2d) Cutting bolt recess slots for female 90

O

connecting

bolt.

P

5.5mm

100mm

EN

CL

CL

8.5mm

8.5mm

CL

CL

8.5mm

Start Here

Start Here

Cut with laminate down

Cut with laminate up

8.5mm

CL

CL

8.5mm

8.5mm

CL

CL

Engraved lines

Start Here

Start Here

12,7mm

50mm

No.20

PVA

SEALANT

Waterproof

UNIBASE

t

r

e

n

d

3

0

m

m

R

7 5

Female

8

Male

6

Male

45

o

Joint

8 6

Female

9

Male

7

Male

45

o

Joint

4

5

Female

Male

3

2

Female

Male

Joint (35mm Inset)

35mm

Inset

Joint (35mm Inset)

PF

W

90

o

90

o

RH

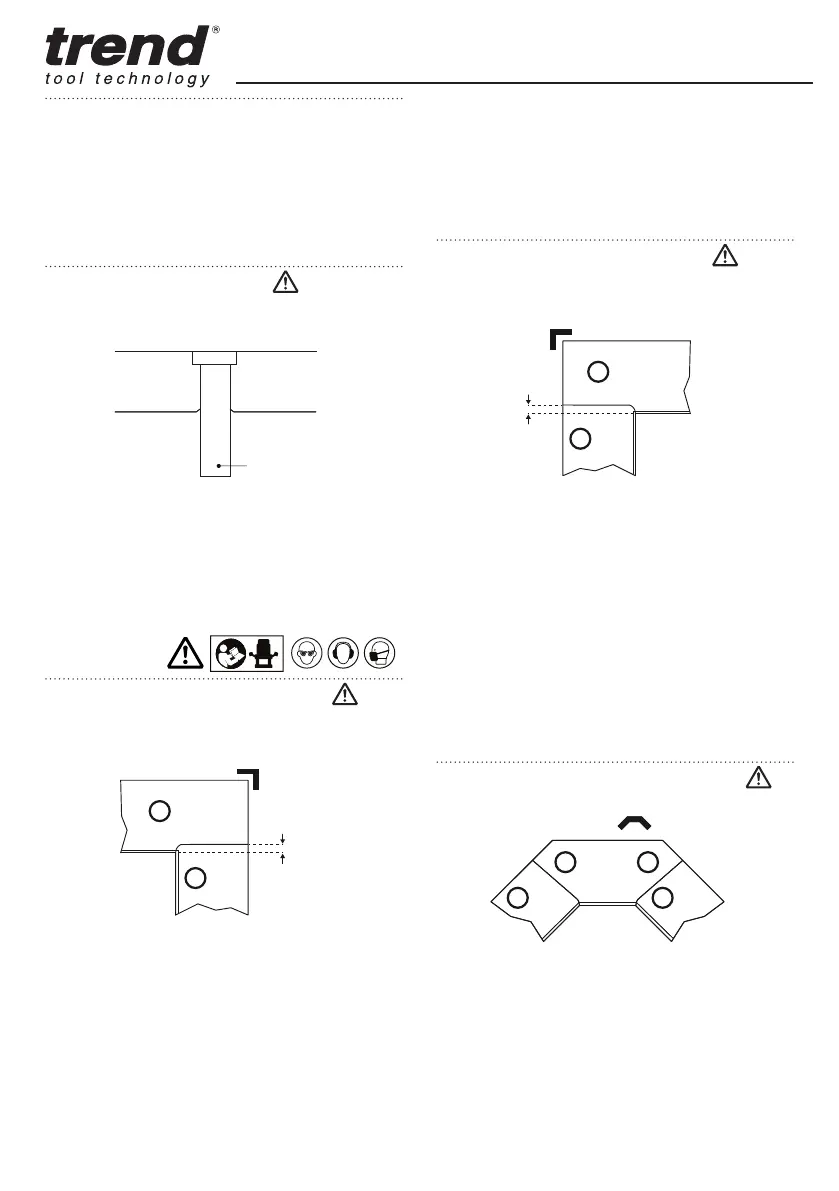

3a) Setting up for Right Hand 90

O

Male Joint.

3b) Routing roughing cuts x 5 for Right Hand 90

O

Male

Joint.

3c) Routing finishing cut for Right Hand 90

O

Male Joint.

3d) Cutting bolt recess slots for Male 90

O

connecting

bolt.

90

O

Left Hand Joint - (Fig.4a-5d)

4a) Setting up for Left Hand 90

O

Female Joint.

4b) Routing roughing cuts x 6 for Left Hand 90

O

Female

Joint.

4c) Routing finishing cut for Left Hand 90

O

Female Joint.

4d) Cutting bolt recess slots for Female 90

O

connecting

bolt.

5a) Setting up for Left Hand 90

O

Male Joint.

5b) Routing roughing cuts x 6 for Left Hand 90

O

Male

Joint.

5c) Routing finishing cut for Left Hand 90

O

Male Joint.

5d) Cutting bolt recess slots for Male 90

O

connecting

bolt.

45

O

Joint (Corner Joint) - (Fig.6a-9d)

6a) Setting up for the Right Hand 45

O

Female Joint.

6b) Routing the Right Hand 45

O

Female Joint roughing

cuts x 5.

6c) Routing the Right Hand 45

O

Female Joint finishing

cut.

6d) Cutting bolt recess slots Female 45

O

connecting bolt.

5.5mm

100mm

EN

CL

CL

8.5mm

8.5mm

CL

CL

8.5mm

Start Here

Start Here

Cut with laminate down

Cut with laminate up

8.5mm

CL

CL

8.5mm

8.5mm

CL

CL

Engraved lines

Start Here

Start Here

12,7mm

50mm

No.20

PVA

SEALANT

Waterproof

UNIBASE

t

r

e

n

d

3

0

m

m

R

7 5

Female

8

Male

6

Male

45

o

Joint

8 6

Female

9

Male

7

Male

45

o

Joint

4

5

Female

Male

3

2

Female

Male

Joint (35mm Inset)

35mm

Inset

Joint (35mm Inset)

90

o

LH

5.5mm

100mm

EN

CL

CL

8.5mm

8.5mm

CL

CL

8.5mm

Start Here

Start Here

Cut with laminate down

Cut with laminate up

8.5mm

CL

CL

8.5mm

8.5mm

CL

CL

Engraved lines

Start Here

Start Here

12,7mm

50mm

No.20

PVA

SEALANT

Waterproof

UNIBASE

t

r

e

n

d

3

0

m

m

R

7 5

Female

8

Male

6

Male

45

o

Joint

8 6

Female

9

Male

7

Male

45

o

Joint

4

5

Female

Male

3

2

Female

Male

Joint (35mm Inset)

35mm

Inset

35mm

Inset

Joint (35mm Inset)

PF

W

90

o

90

o

RH

LH

PF

PF

PF

PF

Loading...

Loading...