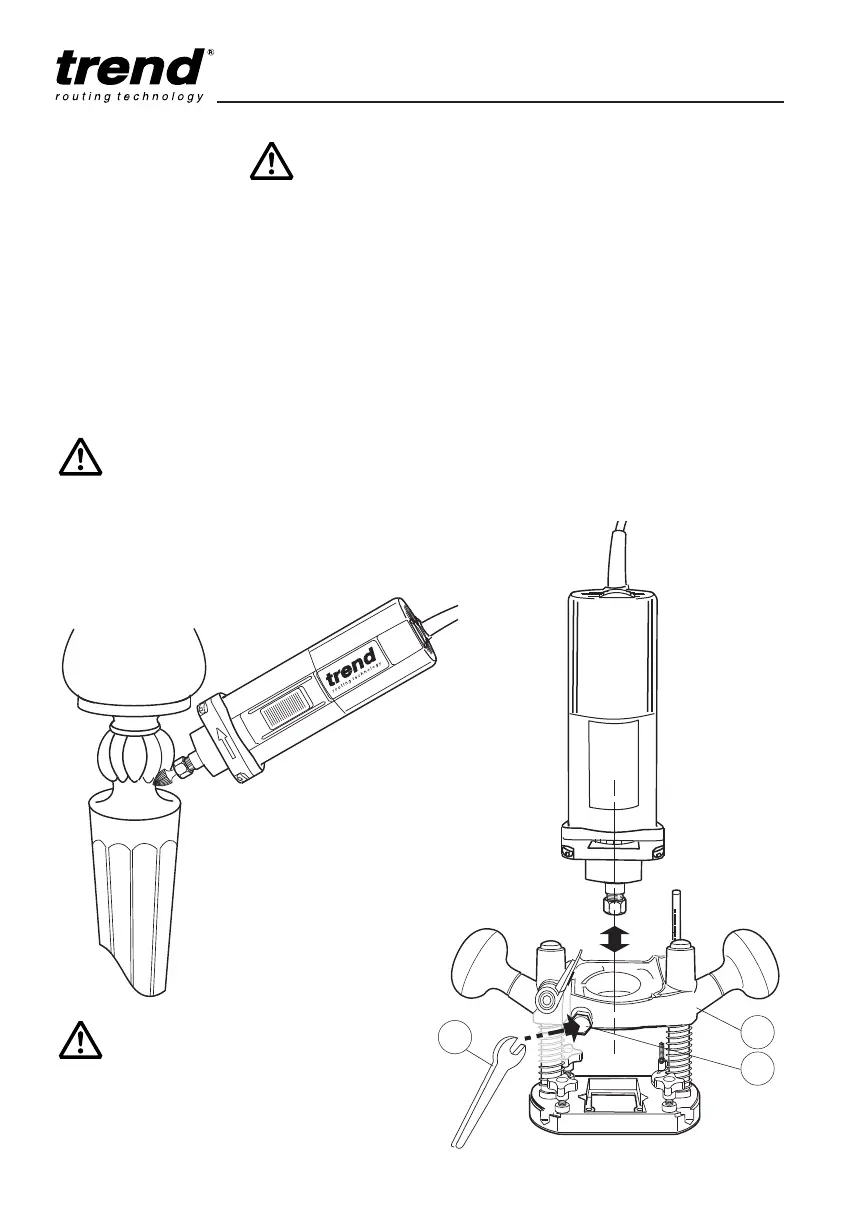

Removing the Router from the Plunge

Base

■ Never separate the router from the base while

a cutter is fitted in the collet. Always

disconnect the router from the power supply

before separating the router from the base.

■ Use the 15mm open ended spanner (1) to

release the clamping nut (2) on the base.

Slacken the nut off until the motor unit slides

out of the base (3).

■ When re-fitting the motor unit, ensure that the

switch is facing the front of the router so that

it is accessible when plunge routing.

■ Ensure that the clamping nut is re-tightened

before using the router for normal plunge

cutting operations.

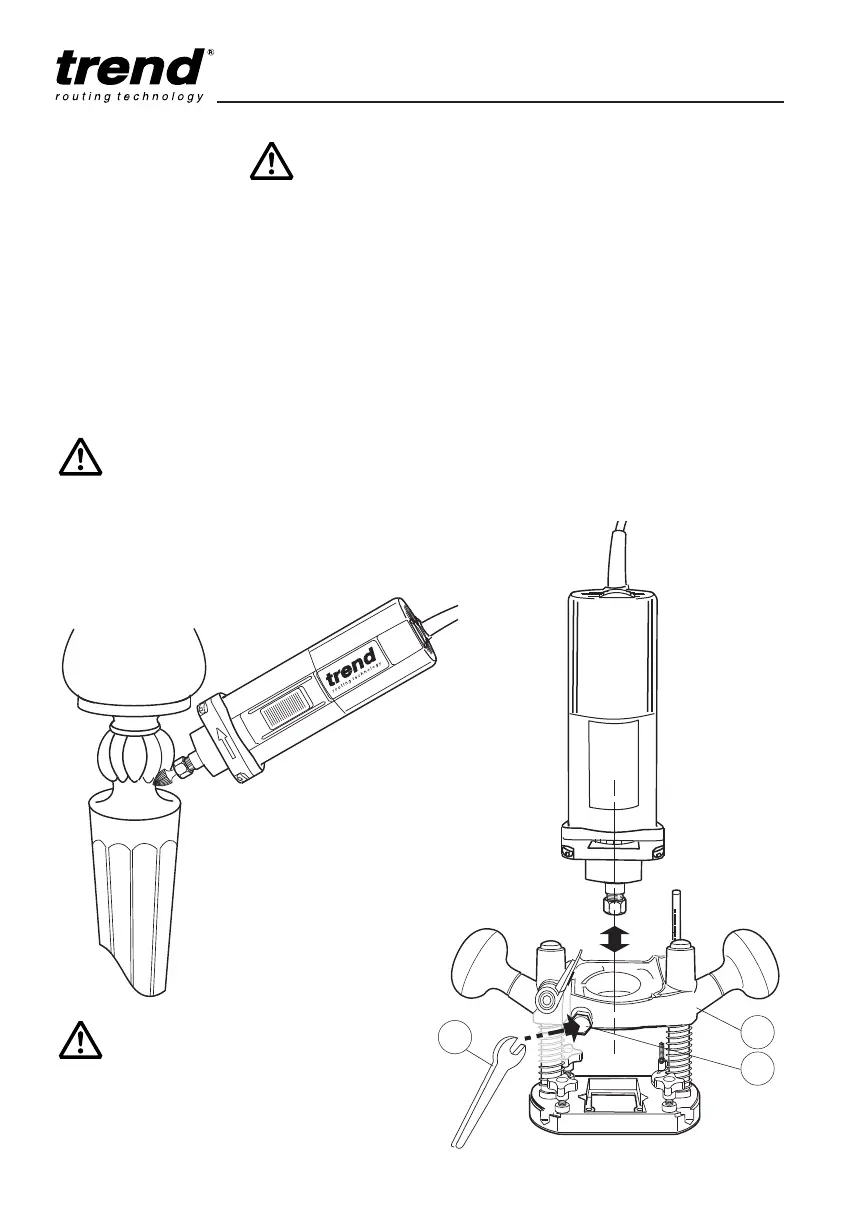

Carving and Grinding

Carving and grinding applications can be carried

out with the router removed from its plunge

base. When using the router in this way, only

use multi flute carving, engraving, or de-burring

rasps and burrs.

The mounting boss on the T3 router has a

diameter of 42mm. To allow the router motor

unit to be mounted in a drill stand for overhead

routing applications a 42mm to 43mm collar is

required, Ref. T3/COLLAR.

Always unplug the machine

from the power supply before

separating the router from its

plunge base.

Never use high speed router

cutters for carving operations.

Loading...

Loading...