-17-

MAINTENANCE AND CARE

Cleaning

■ Keep the machine clean at all times. Some

maintenance products and solvents may

damage the plastic parts, these include

products containing Benzene, Trichloroethyle

Chloride and Ammonia.

■ Never use any caustic agents to clean the

plastic parts.

T3

Ensure machine is isolated from

power supply.

It is advisable to have the

brushes replaced by an

authorised Trend service agent.

The router will also be given a

thorough inspection.

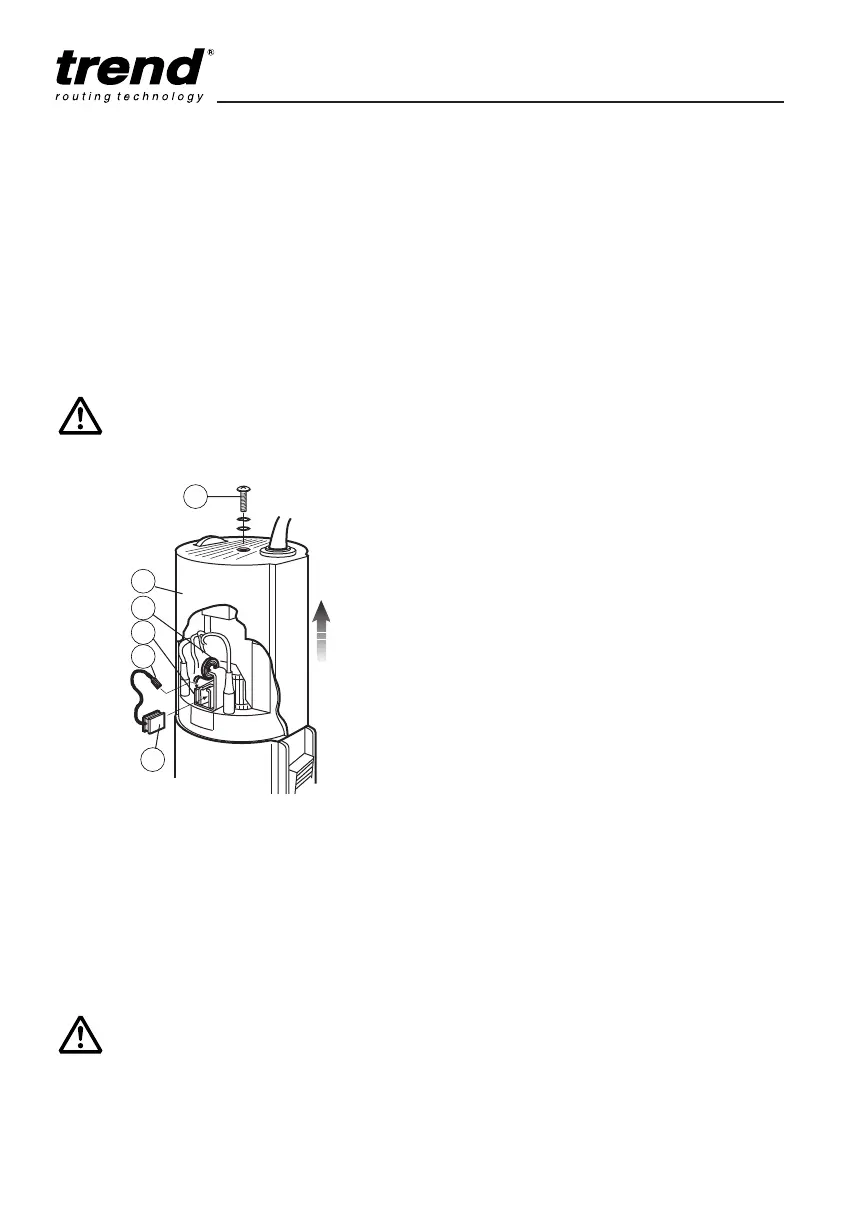

■ Undo the single screw (1) in the top of the

vent housing. Slide the vent housing (2) off.

■ Pull back the spring retaining clip (4). Take

care not to bend or distort the coil spring.

■ Disconnect the wire (5) and remove the

carbon brush (6).

■ Insert the new brush and press the connector

firmly on to the tag (3). Refit the cover.

■ Always use original T3 spare parts.

Changing Brushes

Lubrication

■ The bearings of the machine need no

lubrication, as they are sealed. The two

plunge columns on the routing base should

be slightly oiled from time to time.

■ Keep the cooling vents on the motor housing

clean and unobstructed at all times. Blow out

any dust and dirt at regular intervals.

■ Visually check the carbon brushes. In the

event of excessive sparking, they may need

changing.

■ After about 40 operating hours inspection by

a authorised Trend service agent is

recommended.

RECYCLING

Machine, accessories and packaging should be

sorted for environmentally friendly recycling.

GUARANTEE

The machine carries a manufacturers guarantee

in accordance with the conditions on the

enclosed guarantee card.

For the location of your nearest Trend Service

Agent, please call the telephone number at the

back of this manual.

Loading...

Loading...