Motion Coordinator Technical Reference Manual

Introduction 1-3

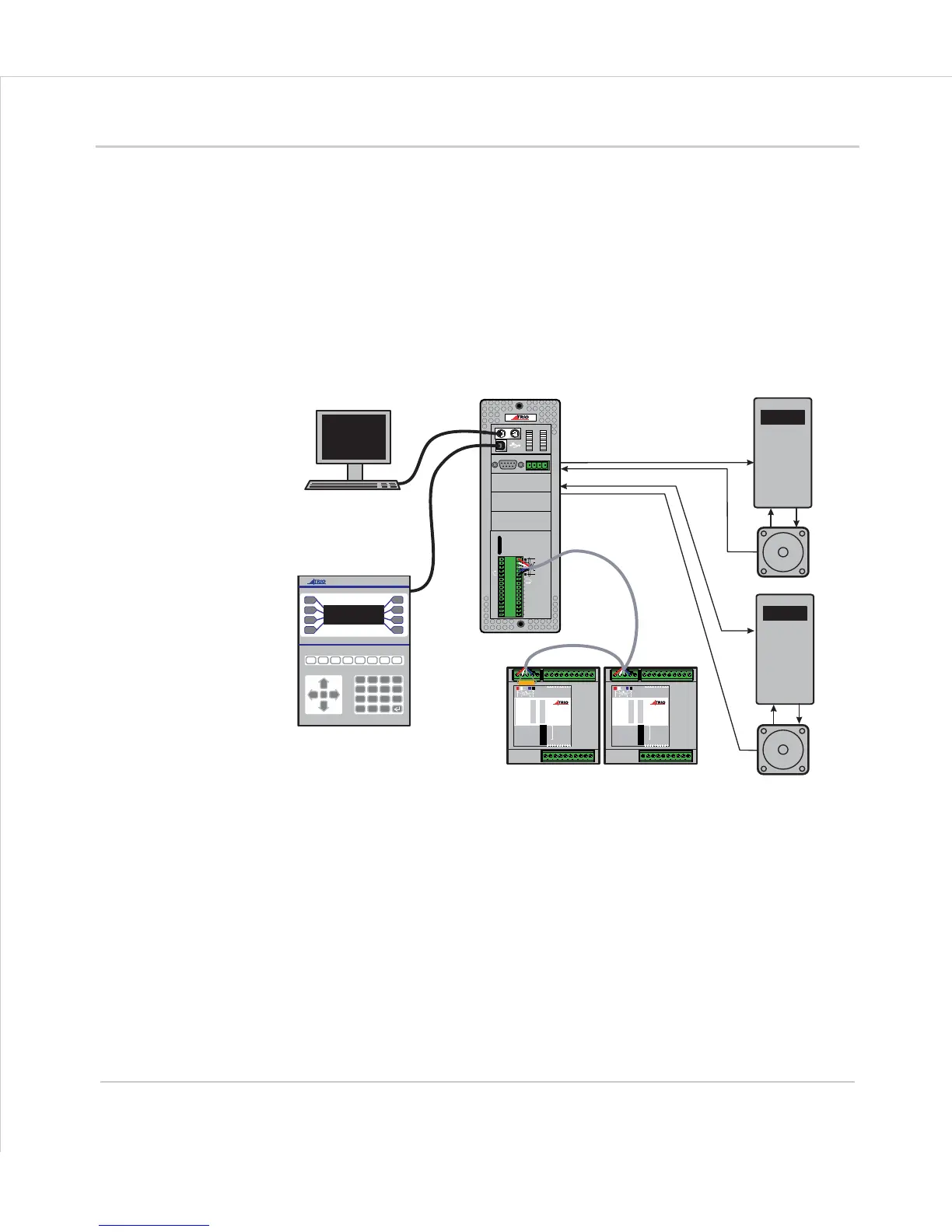

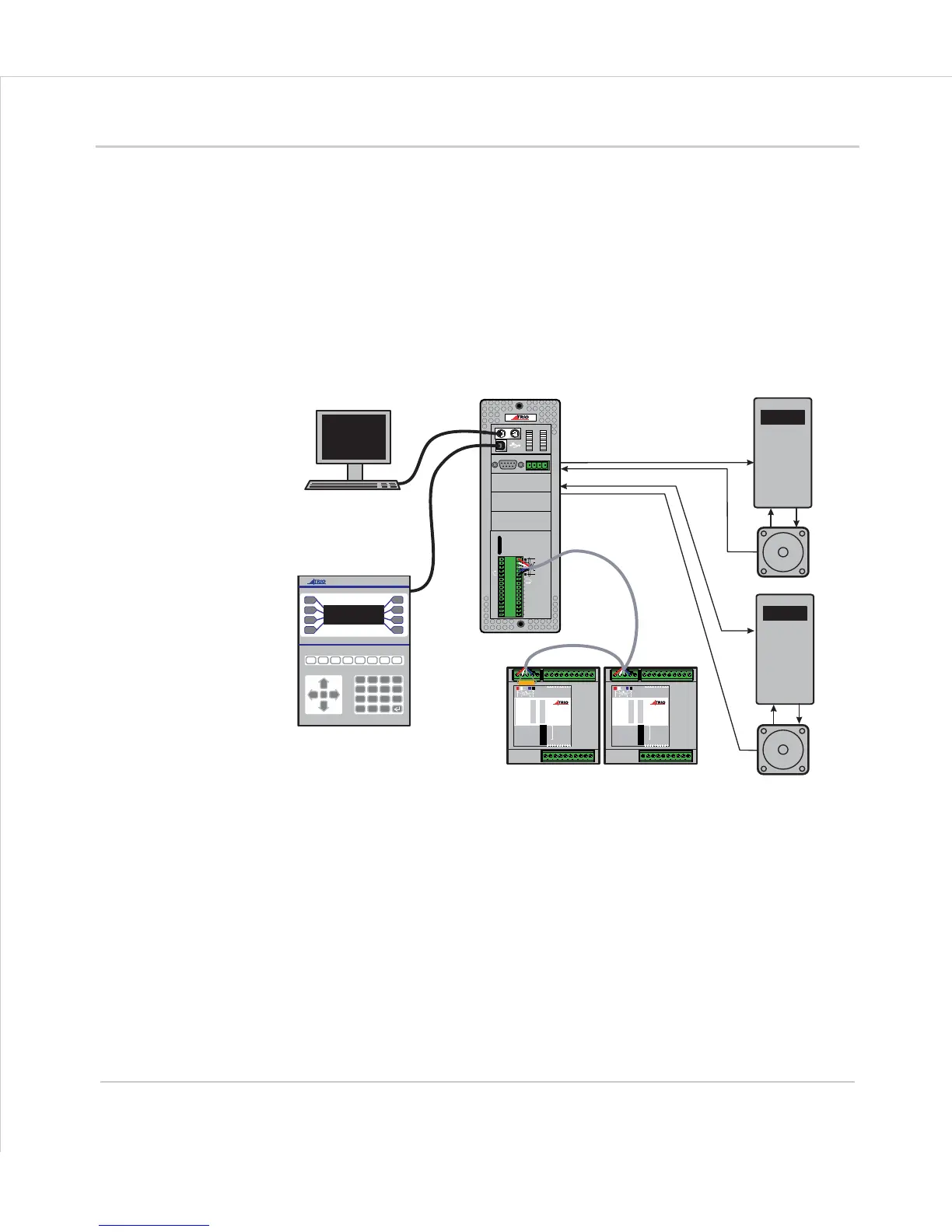

Trio Motion Technology’s range of Motion Coordinator products are designed to

enable the control of industrial machines with a minimum of external compo-

nents. The products may be combined to build a control system capable of driving

a multi-axis machine and its auxiliary equipment. The Motion Coordinator system

described in this manual allows you to control up to 24 servo or stepper motors,

Digital I/O and additional equipment such as keypads and displays from a single

master. Up to fifteen masters can be networked together using the Trio fibre optic

network allowing up to 360 axes of control. The controller is programmed using

the Trio BASIC programming language. This may be used to build stand-alone pro-

grams or commands can be sent from an external computer.

Typical System Configuration

The

Motion

Coordinator system is modular, allowing the user to tailor the controller

to their specific needs, but also allowing the flexibility to incorporate new modules if

needs should change.

ENCODER

V+ V- R

0v

8

9

10

11

12

13

14

15

0

OK

A

B

STA

1

2

3

4

5

6

7

SERIAL

BAT

5 4 3 2 1

9 8 7 6

MOTION

TECHNOLOGY

IO8

IO9

IO10

IO11

IO12

IO13

IO14

IO15

I 0

I 1

I 2

I 3

I 4

I 5

I 6

I 7

24v

0v

A1

A0

A-

B

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

4

8

16

32

OFF

MS NS

PR

DR

10 11 12 13 14 15 24v Ov98

7654 32100v 24v

NODE

ADDRESS

CAN16 -I/O

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

4

8

16

32

OFF

MS NS

PR

DR

10 11 12 13 14 15 24v Ov98

7654 32100v 24v

NODE

ADDRESS

CAN16 -I/O

7

4

1

-

8

5

2

0

9

6

3

.

Y

N

CLR

PC for Programming

Operator Interface

Motion Coordinator

CAN I/O

Servo Drive

Servo Drive

Motor

Motor

MOTION

TECHNOLOGY

MOTION

TECHNOLOGY

MOTION

TECHNOLOGY

Loading...

Loading...