8 EN

layer thickness measuring device BB20

Zero point calibration

ü An uncoated sample is required.

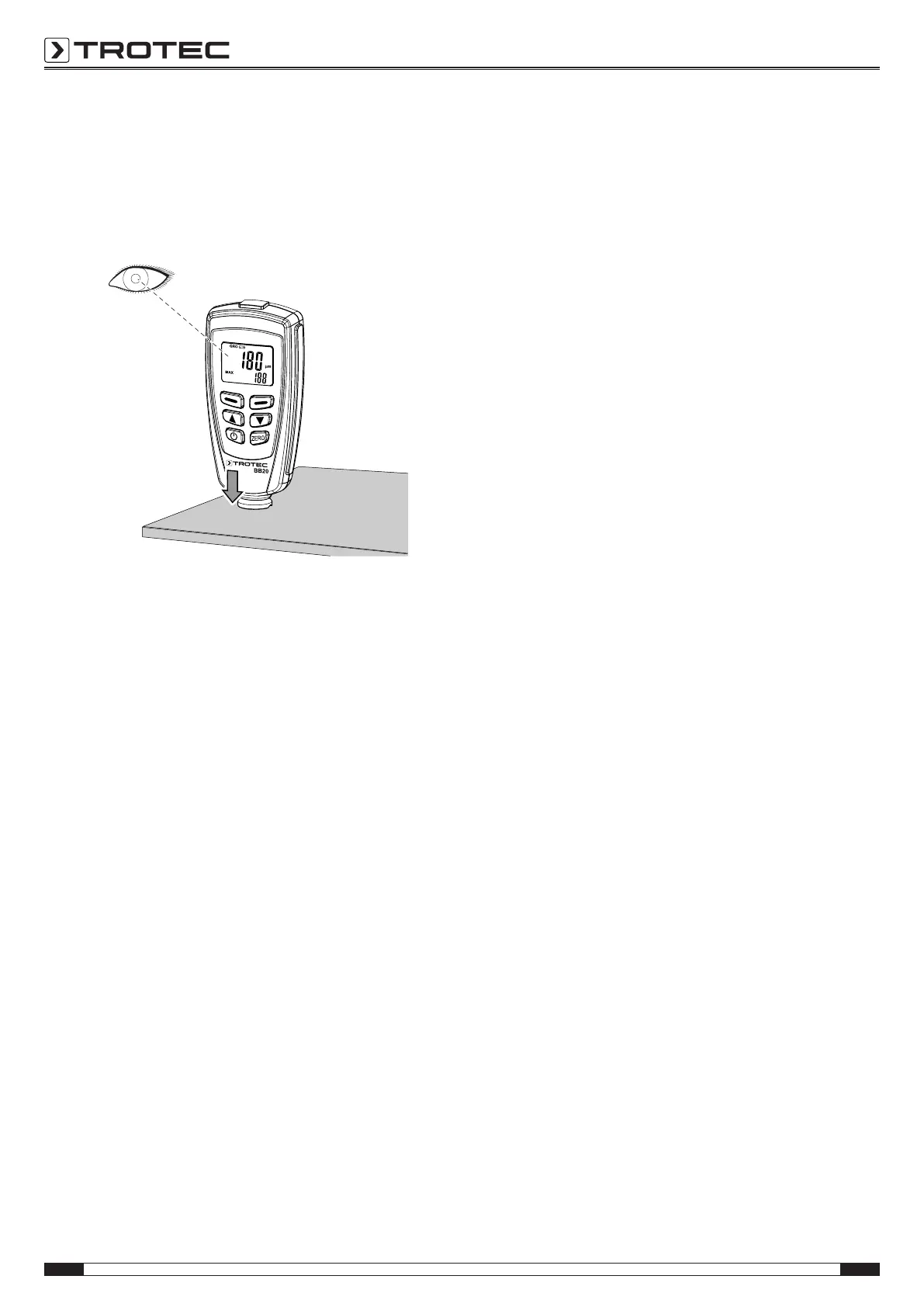

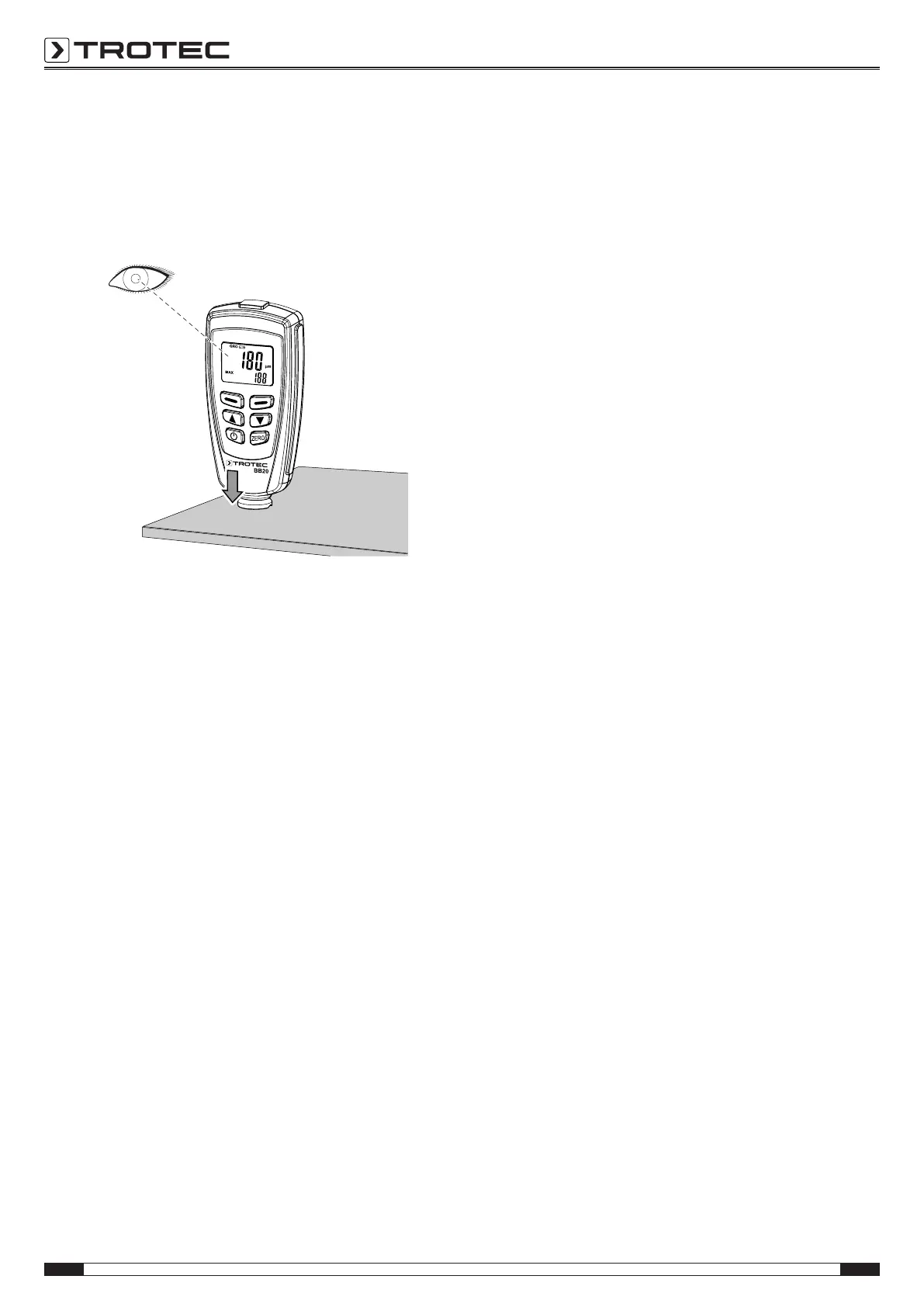

1. Place the sensor onto an uncoated sample. The calibration

sample is to be identical with the actual sample in terms of

material composition, shape and surface condition.

ð The following message will be displayed:

<x.x μm>

2. Lift the sensor again and keep it away from the sample (at

least 10cm).

3. Press and hold the Zero button(4) for approx. 2seconds.

ð The following result appears on the display:

<0.0μm>

CAL1

ZeroY

ð The calibration is terminated.

One-point calibration

This calibration is suited for high-precision measurements, e.g.

for thin coatings.

ü A calibration film, a coated and an uncoated sample are

required.

1. Activate the calibration mode as described before.

2. Carry out a zero-point calibration.

3. Place the calibration film on an uncoated sample.

4. Place the sensor on the sample.

ð The measurement is effected.

5. Lift the sensor again.

6. Adjust the required film thickness by using the Down/

Right(3) or the Up/Left(8) button. The film thickness

should be at least the size of the estimated coating

thickness.

7. Repeat this step several times.

8. Now carry out the measurement on a coated sample.

9. Press the Zero button(4) to adopt the current calibration.

10. To exit the current calibration, press the Blue button(2).

Two-point calibration

This calibration is especially suited for measurements on rough

surfaces or for high-precision measurements.

ü You need two films of different film thickness. The thicker

film should be approx.1.5 times thicker than the thinner

film.

1. At first, carry out a zero-point calibration.

2. Using the first film, carry out a one-point calibration.

3. Repeat this step with the second film.

4. Place the sensor onto the coating that is to be measured.

After a brief acoustic signal is emitted, you can lift the

sensor again.

ð The measured value appears on the display.

Calibration on radiated surfaces

Values of layer thickness measurements carried out on radiated

surfaces are usually too high. The average thickness can be

determined as follows:

Method A

1. Carry out the steps for one-point and two-point calibration

as described above. Use a smooth sample with the same

surface curvature and material type as the measuring

object that is to be used later on.

2. In order to determine the average value Xo, carry out

approx.10 measurements on the uncoated sample.

3. Afterwards, carry out approx.10 measurements on the

coated sample to determine the average value Xm.

ð The difference between both average values is the

average coating thickness Xeff. Take the standard

deviation of both values Xm and Xo into account.

Xeff= (Xm - Xo)±S

Method B

1. Carry out a zero calibration with approx.10measurements

on an uncoated sample.

2. Afterwards, carry out a film calibration on the uncoated

sample.

3. Repeat this calibration with films of different thicknesses

(max. thickness50μm). Together, these films should be as

thick as the assumed layer thickness.

ð The layer thickness can be read from the display.

Method C

1. Carry out the steps for two-point calibration with two films

as described above.

2. Use several 50μm films to approach the actual surface as

precisely as possible.

ð The layer thickness can be read from the display.

Loading...

Loading...