4

VFC

Operating manual

TROX air terminal units

Type VFC volume ow controllers

VFC

Installation

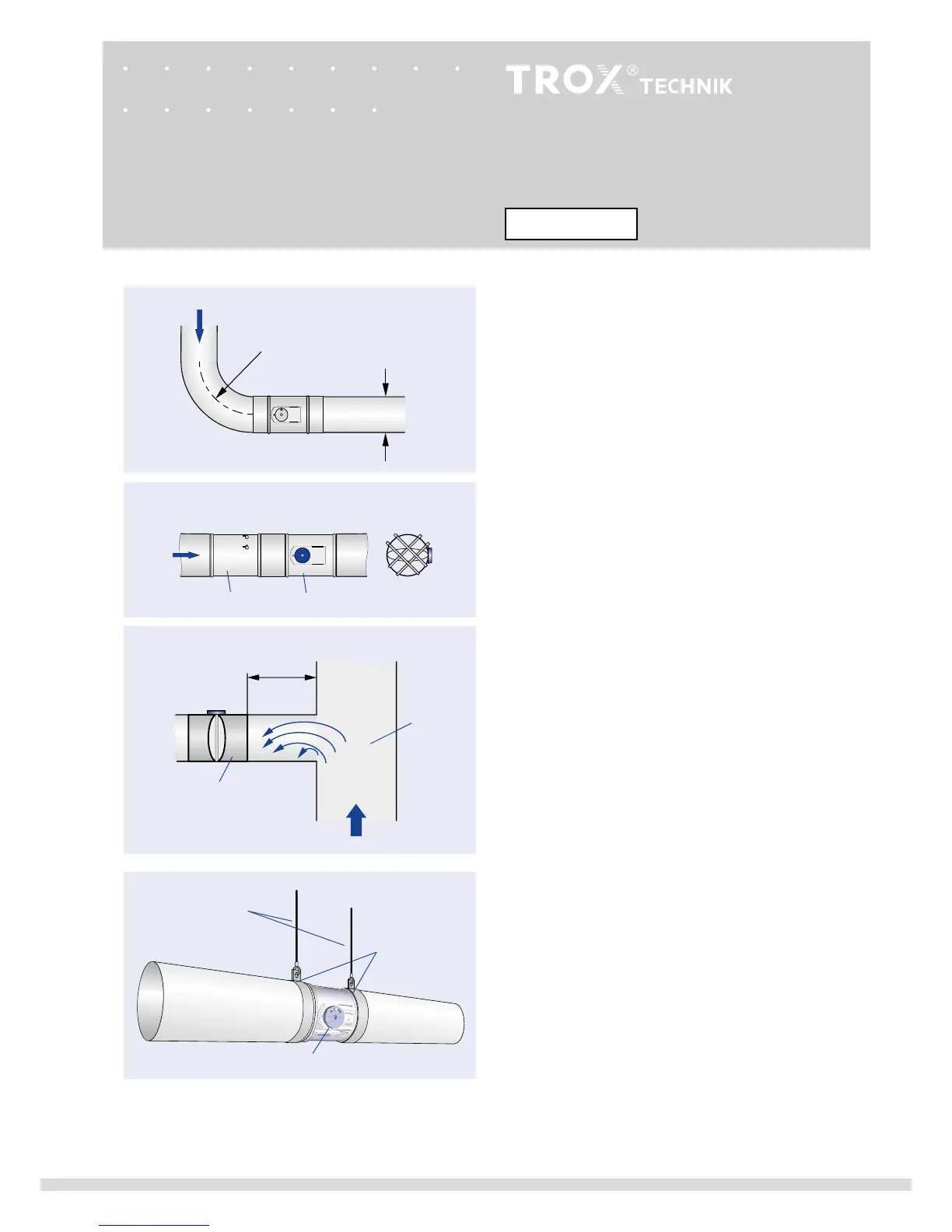

1.5 D

VFC

VFC

Manifold

Installation in a branch

Connection with ducting

Installation behind a bend

Combination with volume ow rate measuring unit

VFC

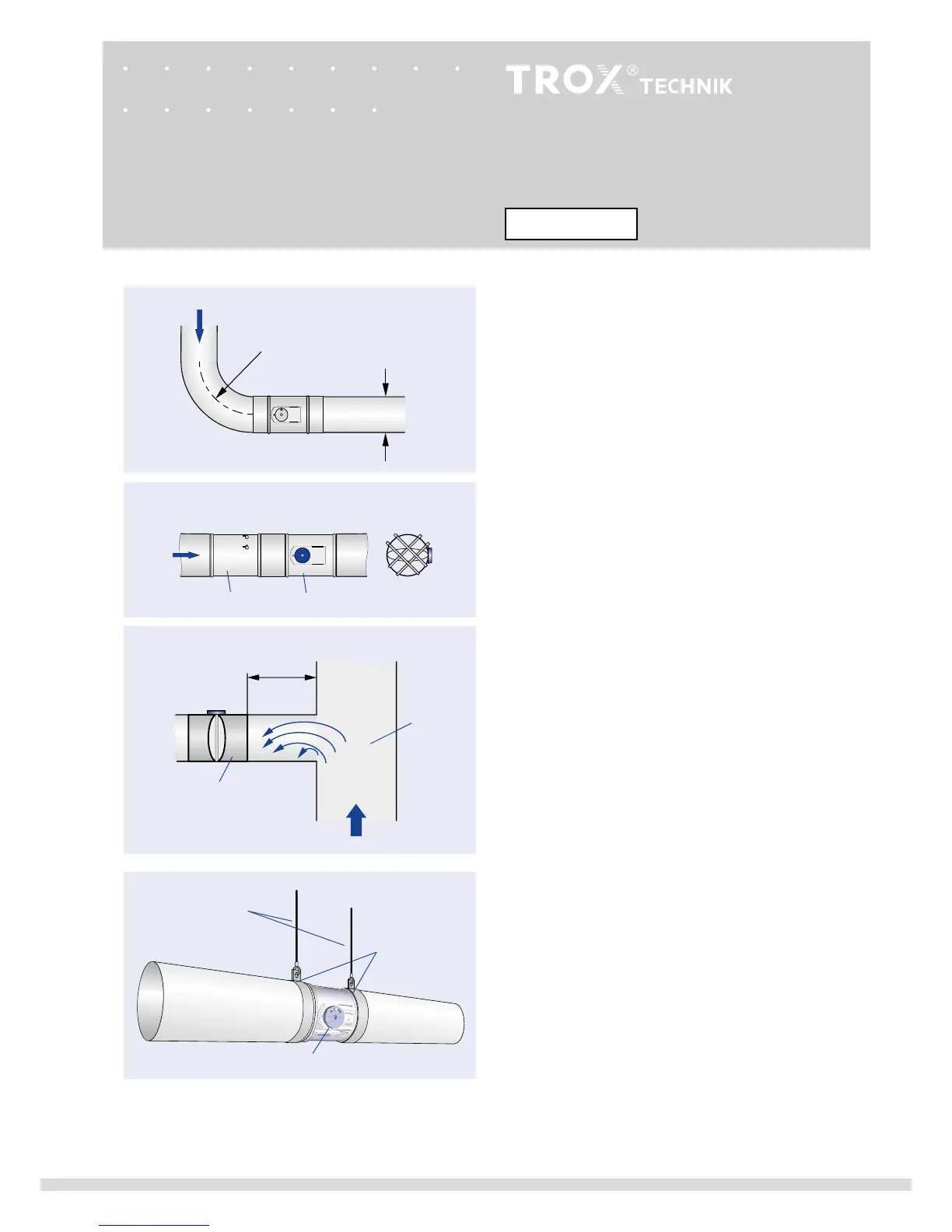

Suspension

D

min. 1 D

Connection

elements, e.g.

tube clamp with

rubber seal

Installation location and type of connection

• Select the installation location so the scale and

characteristic of the controller remain accessible.

• With reference to the characteristic, set the pointer to the

required volume ow rate.

• Horizontal or vertical controller installation.

• Note the airow direction according to the arrow on the

characteristic.

• Note for installation in front of and behind elbows, aps

or other obstacles with aerodynamic and acoustic eects.

• Horizontal or vertical installation; in combination with

volume ow rate measuring unit (VMR), arrange the sensor

tubes at 45° oset from the controller axis.

• Installation behind a bend:

Maintain a curvature radius of at least 1D unless there

is an additional straight inow length.

• Direct connection to a main duct/manifold: Maintain at least

1.5 D straight inow length

• Shorter inow lengths result in tighter tolerances.

• Direct connection to a main duct is permitted without

perforated sheet metal in extract air operation.

• Free intake not permitted, inow length 1.5 D required.

Inow nozzles are recommended in order to reduce the

pressure losses.

Connection with ducting

The connection diameters are appropriate for tubes

according to EN 1506 or EN 13180.

• No drilling work is allowed to be performed on the

controller!

• Before connecting the controllers, check the ducting

for contamination.

• Use standard TROX lip seals for connecting to the ducting.

VMR

Loading...

Loading...