4.

Before removing any further parts, inspect the condi-

tion ofthe flail cutting blades. Use a flashlight

to

exam-

ine them by looking into the service

door

opening

or

the discharge area opening. You'll

see

twofree-swinging

blades, separated

by

a spacer, on each

of

two

cylinder

pins.

A

DANGER

BEFORE

PERFORMING

THE

FOLLOWING

PROCEDURE, BE SURE

TO

DISCONNECTTHE

SPARK PLUG WIRE.

If any

of

the

four

blades is difficult

to

see, simply pull

out

the starter rope a little

to

cause the rotor/blade

assembly

to

turn - watch

your

fingers because the

shredder flail blades and the chipper blade are ex-

tremely sharp! While you're looking inside, inspect the

chipper

blade

for

nicksand cracks. Ifthe cutting edges

seem

to

be in

good

condition,

your

inspection

is

com-

plete. Refer

to

Photo 5-9. If one

or

more shredder

blades

is

worn

or

any spacers are damaged,

or

the

chipper blade mustbe removed, continue on with Step

5.

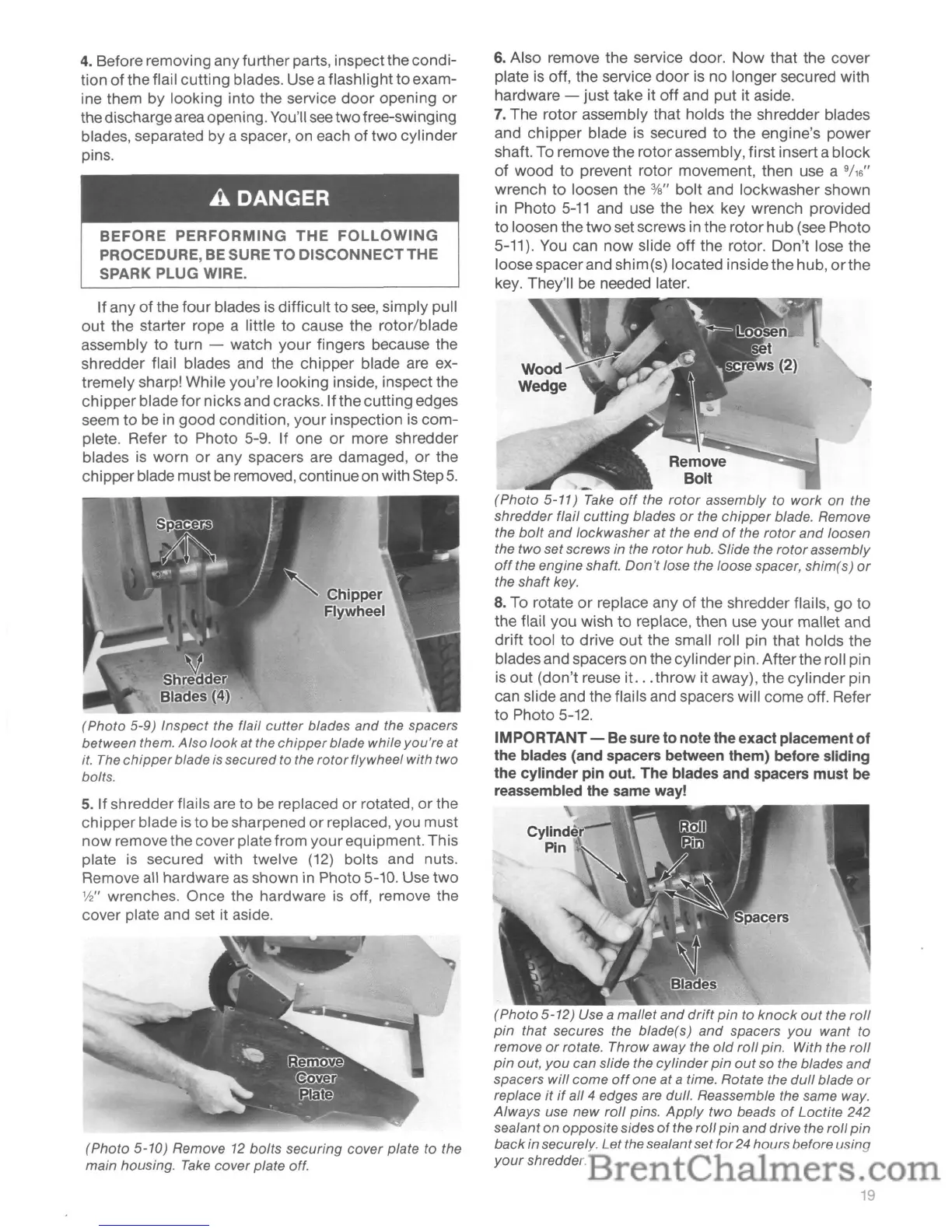

(Photo 5-9) Inspect the flail

cutter

blades

and

the spacers

between them.

Also

look

at

the

chipper

blade while you're at

it.

The

chipper

blade is secured to the

rotor

flywheel with two

bolts.

5.

If shredder flails are to be replaced

or

rotated,

or

the

chipper blade is to

be

sharpened

or

replaced, you must

now

remove the cover plate from

your

equipment. This

plate

is

secured with twelve

(12)

bolts and nuts.

Remove all hardware

as

shown in Photo 5-10. Use

two

1f2"

wrenches. Once the hardware

is

off, remove the

cover plate and set it aside.

(Photo 5-10) Remove 12 boits securing cover plate to the

main housing.

Take

cover plate off.

6.

Also remove the service door.

Now

that the cover

plate

is

off, the service

door

is no longer secured with

hardware - just take it off and put it aside.

7.

The rotor assembly that holds the shredder blades

and

chipper

blade is secured

to

the engine's power

shaft. To remove the

rotor

assembly, first inserta block

of

wood

to

prevent rotor movement, then use a

9/

16

"

wrench

to

loosen the %" bolt and lockwasher shown

in Photo

5-11

and use the hex key wrench provided

to

loosen the

two

set screws in the

rotor

hub (see Photo

5-11). You can

now

slide

off

the rotor. Don't lose the

loose spacerand shim(s) located inside the hub,

orthe

key. They'll

be

needed later.

Remove

Bolt

(Photo

5-11)

Take

off

the

rotor

assembly to

work

on the

shredder flail

cutting

blades

or

the

chipper

blade. Remove

the

boit

and

lockwasher

at

the

end

of

the

rotor

and

loosen

the two set screws in the

rotor

hub. Slide the

rotor

assembly

off

the engine shaft.

Don't

lose the loose spacer, shim(s)

or

the shaft key.

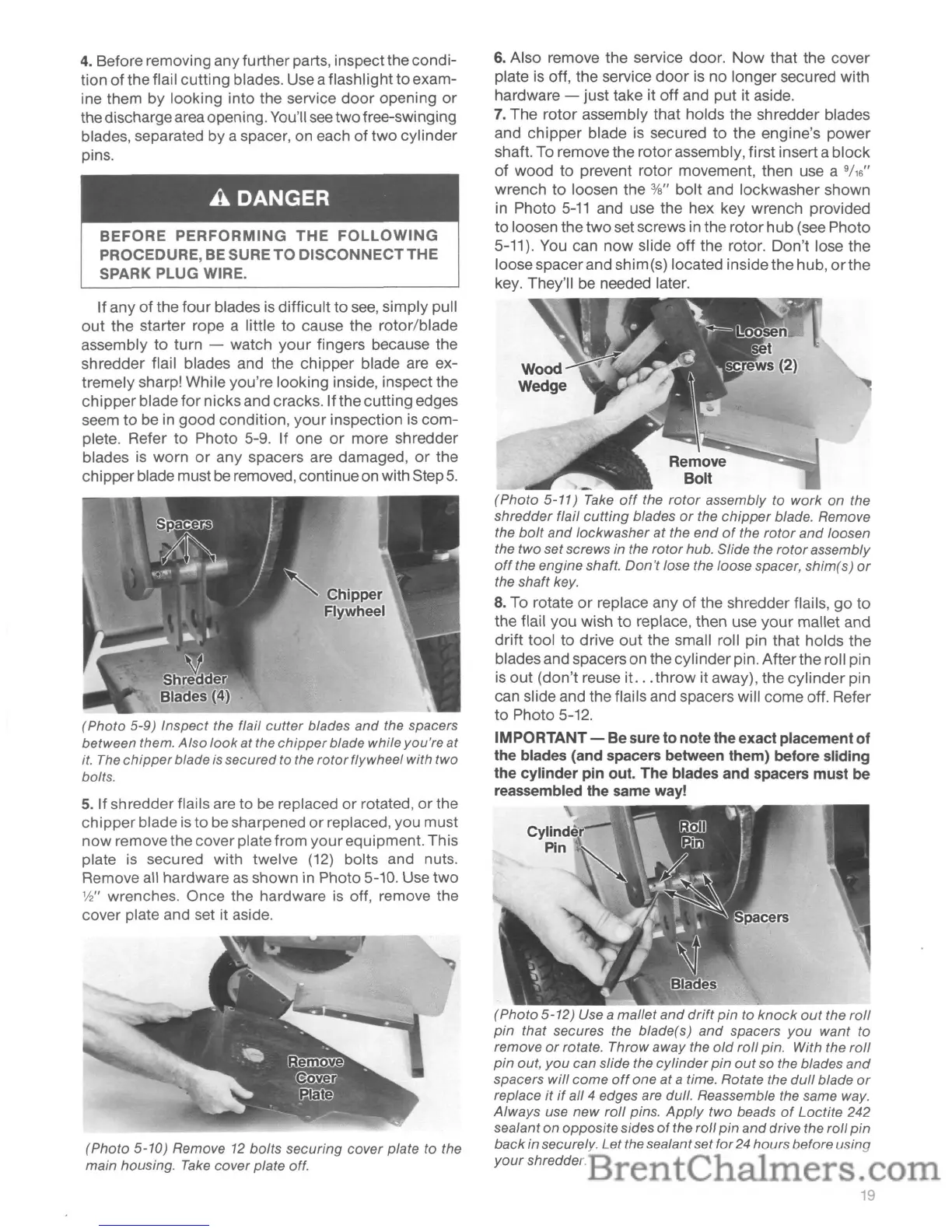

8.

To rotate

or

replace any

of

the shredder flails,

go

to

the flail you wish

to

replace, then use

your

mallet and

drift tool

to

drive

out

the small roll pin that holds the

blades and spacers on the cylinder pin. Afterthe roll pin

is

out

(don't reuse it.

..

throw

it away), the

cylinder

pin

can slide and the flails and spacers will come off. Refer

to

Photo 5-12.

IMPORTANT- Be sure

to

notethe exact placement

of

the blades (and spacers between them) before sliding

the

cylinder

pin out. The blades and spacers must be

reassembled the same way!

(Photo

5-12)

Use a mallet

and

drift

pin

to

knock

out

the

roll

pin

that secures the blade(s)

and

spacers

you

want

to

remove

or

rotate.

Throwaway

the

old

roll

pin. With the

roll

pin

out,

you

can slide the

cylinder

pin

out

so the blades

and

spacers

will

come

off

one

at

a time. Rotate the

dull

blade

or

replace

it

if

all 4 edges are dull. Reassemble the same way.

Always

use

new

roll

pins.

Apply

two beads

of

Loctite 242

sealant on oppositesides

of

the roll pin

and

drive the roll

pin

back

in securely. Letthe sealant set for 24 hoursbefore using

your

shredder.

19

Loading...

Loading...