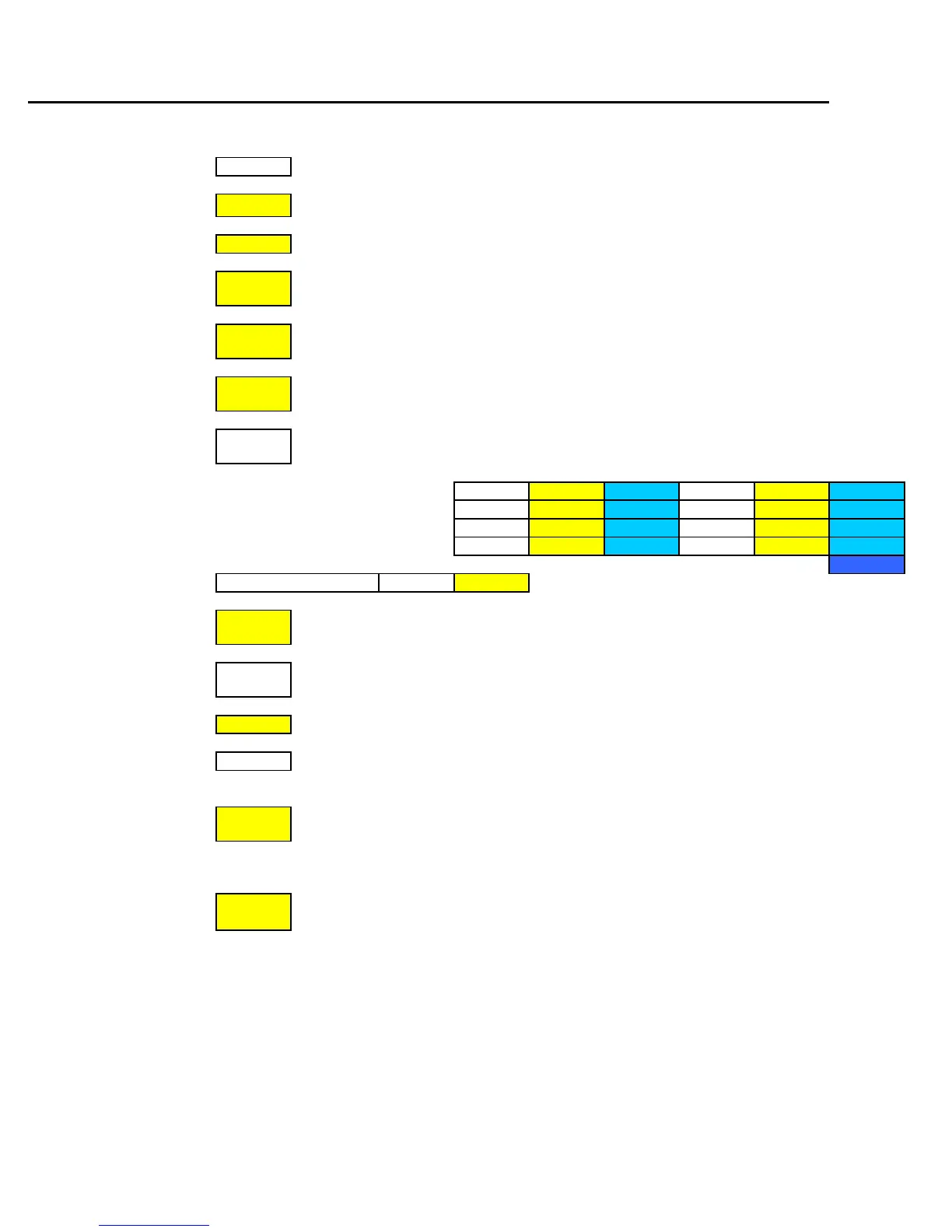

Project No. File:

Model:

@

= 40.281

% Oxygen = 21.04

%O

2

% Carbon = 0.01 %CO2

Temperature

= 28.6 °C

Pressure

= 744 mmHg

Pressure

= -2.032

mm H2O

root ∆P

= 1.867

∆P mm H2O

Pressure CFM Pressure CFM

3.556 496

2.794 510

3.81 530

3.556 515

3.81 520

3.302 510

3.556 520

3.556 499

Average 512.5

8

Temperature

= 22 °C

Coefficient

= 0.84

% Moisture

= 49.7

Sample Rate

= 21.24 Lpm

Size

11.298 mm

0.444803 in

Size Used

1/2 in

Temperature inside stack during operation

Barametric pressure at location of meter

Static Pressure inside of duct

Enter pressure differential at each transvers point in mm

H2O, the take square root of ∆P.

This number is calculated when device is calibrated

Oxygen inside stack during operation

Carbon Dioxide inside stack during operation

09NK11970

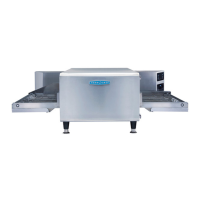

TurboChef Technologies

Calculations needed for Nozzle Size

E151487

NGO

# Travers Points

When numbers are entered into calculator, ideal nozzle

size will be displayed. Enter number here

If ideal nozzle size is not available, locate nearest

number. Enter what nozzle size was used for testing

Loading...

Loading...