Page 8 of 9

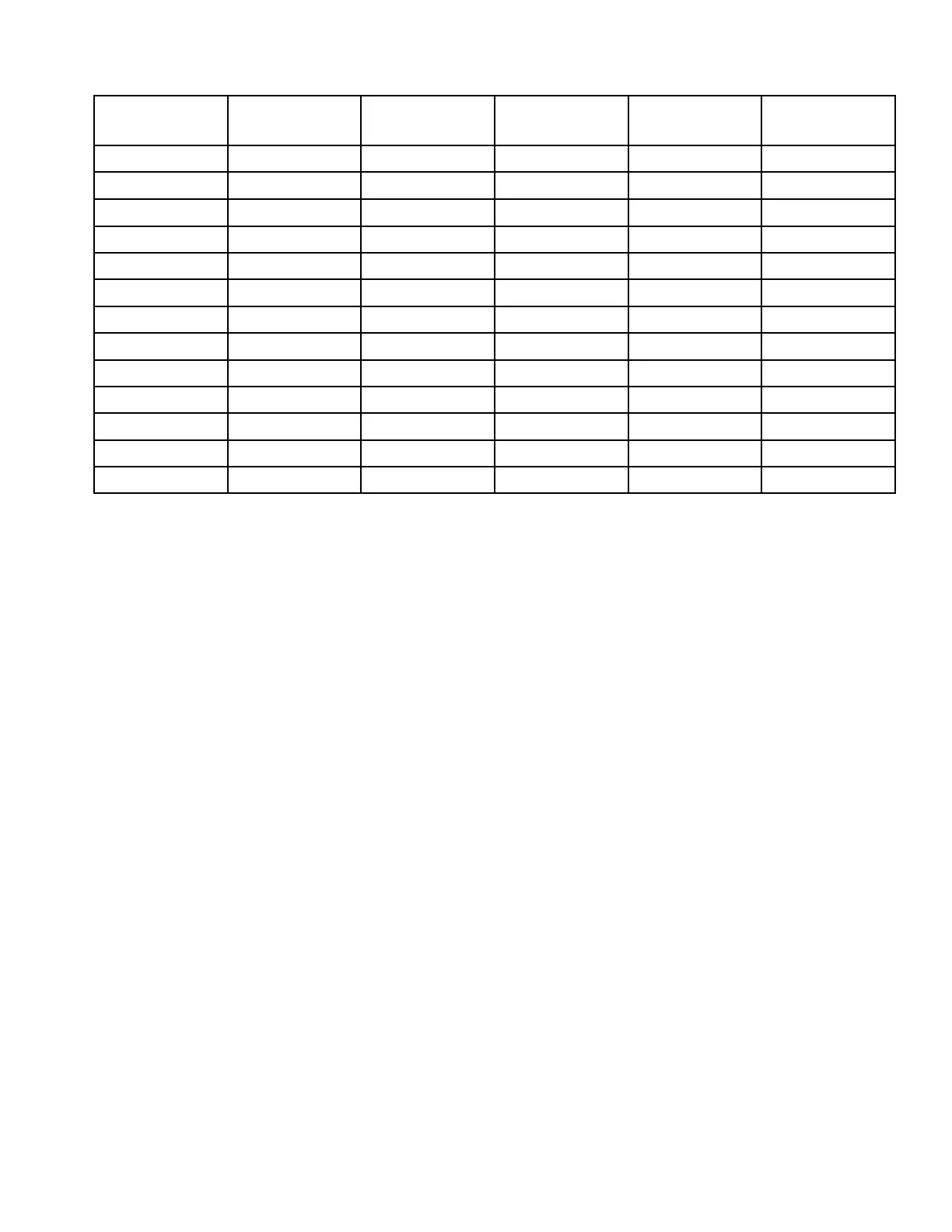

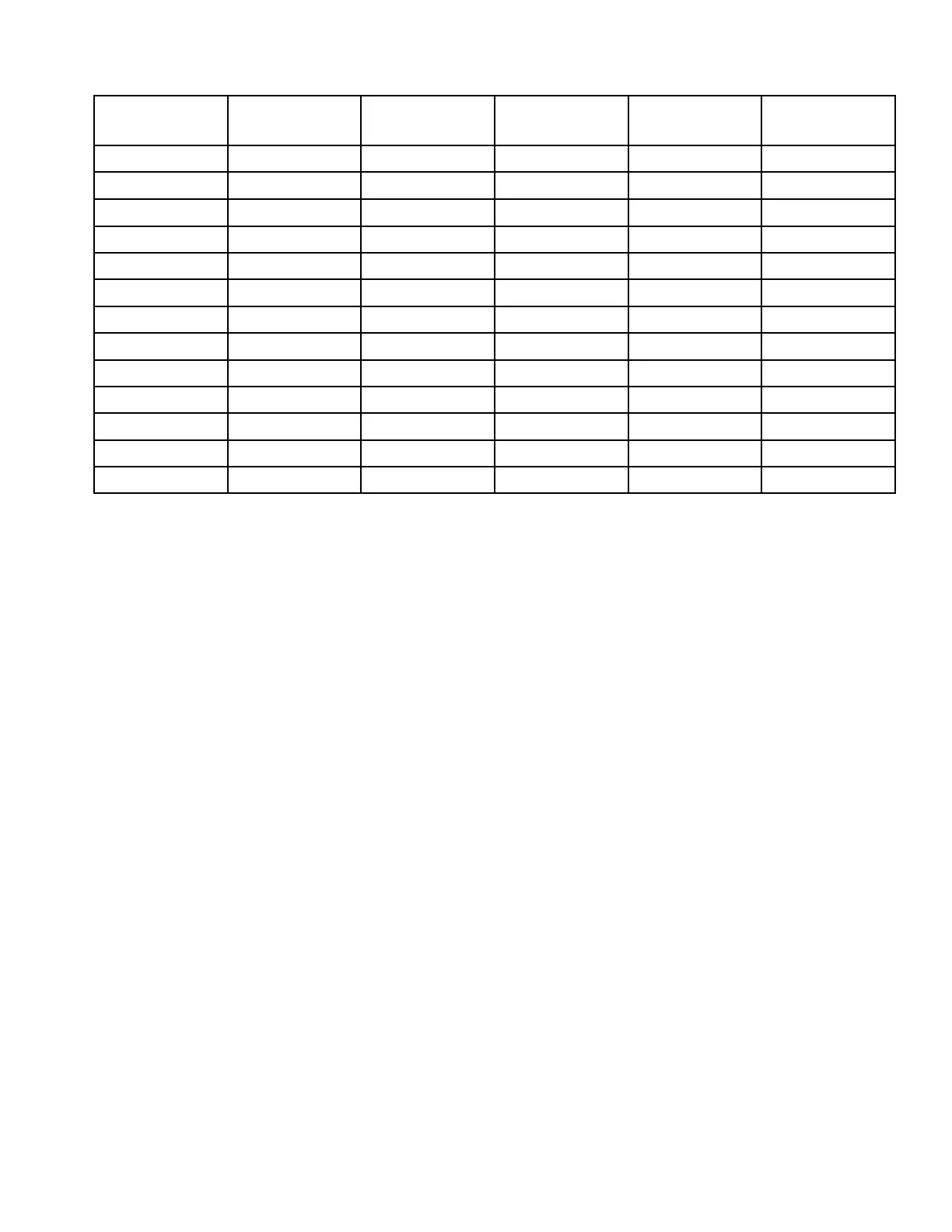

1012 - 1022 Parts List

Item Description Quantity

Drawing

Number

Part

Number

Material

1 Relief Valve 1 A112UK LXUK9219 Various

2 Cover 1 A1066UK 3M35-XUK9014 Cast Iron

3 O’Ring 1 BS046 Neoprene

4 Idler Gear 1 11002-A 3M5-1 Steel/Carbon

5 Body 1 1015-015 Cast Iron

6 Bearing 1 2RLS6/2RS

7 Mechanical seal 1 680-111-23AX12

8 Bearing 1 2RLS6/2RS

9 Circlip 1 NAM300-187

10 Rotor 1 A21445UK Steel

11 Seal Housing 1 1015-012 Cast Iron

12 Shims 2 0.006” Melonex

13 Idler Pin 1 5225-A 3M31 Steel

Field Checklist

1. No Oil is Delivered

• Suction lift too high for vapour pressures of liquid pumped

• While Tuthill Pumps will develop as high as 27 inches of vacuum, it is wise to reduce the vacuum to a minimum

• Bad leaks in suction line or port passages can be detected by submerging pressure line from discharge side of pump into a

pail of oil where the air will be seen in the form of bubbles

• Wrong direction of shaft rotation (In “R” models, check position of cover boss)

• Pump shaft not rotating (Check coupling or drive)

• Relief valve setting too low (Discharging uid through by-pass port)

2. Capacity is too Low

• Suction lift too high

• Air leaks in suction line

• Suction line too small (Can be detected by installing a vacuum gauge directly at the pump suction

• Pump speed too slow

• Filter too small or obstructed

• Suction pipe or port not immersed in the liquid deep enough

• Piping improperly installed, permitting air pocket to form in pump

• Increased clearance or wear in the pump will sometimes cause the pump to deliver an insucient supply of liquid

• A folded gasket or a slight amount of dirt not only will frequently exaggerate the original trouble but will also be the cause

of leakage

Note: The maximum vacuum at the pump suction should never exceed 15 inches of mercury. Not because of the inability of the pump

to handle a higher vacuum, but primarily because the vaporization that is liable to take place at a higher vacuum. Vaporization caused

by higher vacuums will generally result in capacity drop-o.

Loading...

Loading...