TFP1410

Page 10 of 14

NOTES: Wet Pilot Lines must be main-

tained at a minimum temperature of

40°F (4°C).

At a minimum, it is recommended that

internally galvanized pipe and cast iron

fittings be used for wet pilot lines.

System Air Pressure Requirements

The supervisory air (nitrogen) pressure

is to be 10 ± 2 psi (0,69 ± 0,14 bar). The

use of a higher supervisory pressure

is subject to approval by the author-

ity having jurisdiction, and it should be

understood that the use of a higher su-

pervisory pressure may increase water

delivery time. The use of a lower su-

pervisory pressure may prevent clear-

ing the alarm of the Supervisory Low

Pressure Alarm Switch (Item P3 - Fig.

3A), which is factory set to alarm at 5

± 1 psi (0,34 ± 0,07 bar) on decreas-

ing pressure. The supervisory air sup-

ply pressure of 10 ± 2 psi (0,69 ± 0,14

bar) can be provided by any of the fol-

lowing methods. Refer to the applica-

ble data sheet for laboratory approval

information.

•

Model G16AC812 (self-contained)

Automatic Supervisory Air Supply

described in Technical Data Sheet

TFP1620.

• A maximum 200 psi (13,8 bar) plant

air supply in combination with the

Model AMD-1 Air Maintenance De-

vice described in Technical Data

Sheet TFP1221.

• A maximum 3000 psi (206,9 bar) ni-

trogen cylinder in combination with

the Model AMD-3 Nitrogen Mainte-

nance Device described in Technical

Data Sheet TFP1241.

NOTE: The dew point of the air or ni-

trogen supply for a system exposed to

freezing conditions must be maintained

below the lowest ambient temperature

to which the system piping will be ex-

posed. Introduction of moisture into

the system piping can create ice build

up that could prevent proper operation

of the system.

The Supervisory Low Pressure Alarm

Switch (Item P3 - Fig. 3A) is factory set

at 5 ± 1 psi (0,34 ± 0,07 bar) on de-

creasing pressure. The Pressure Relief

Valve (Item P4- Fig. 3A) is factory set to

fully open at 25 ± 2 psi (1,72 ± 0,14 bar)

and it begins to crack open at a pres-

sure of about 18 psi (1,24 bar).

Friction Loss

The nominal pressure loss versus ow

data for the DV-5 Deluge Valve plus

Riser Check Valve is provided in Graph

A.

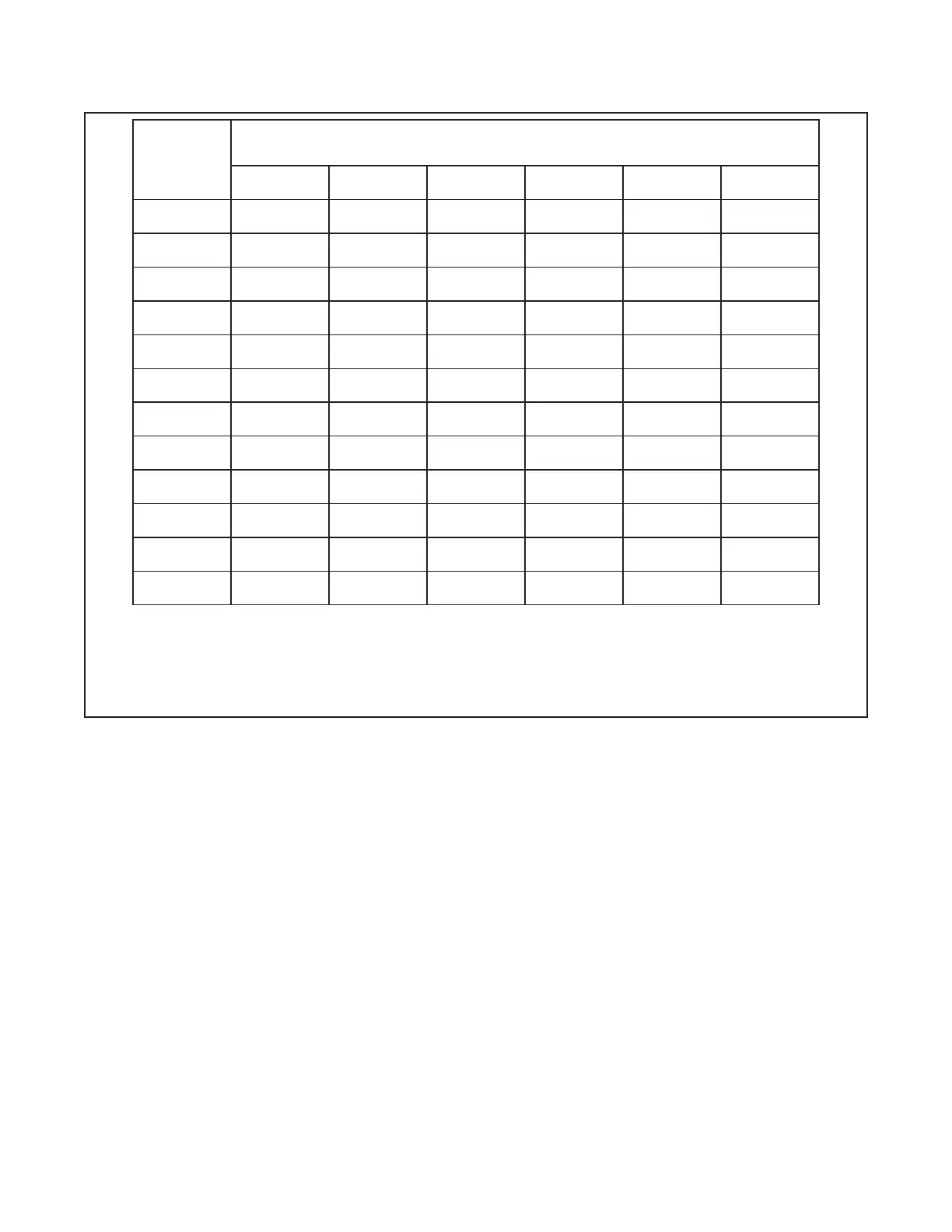

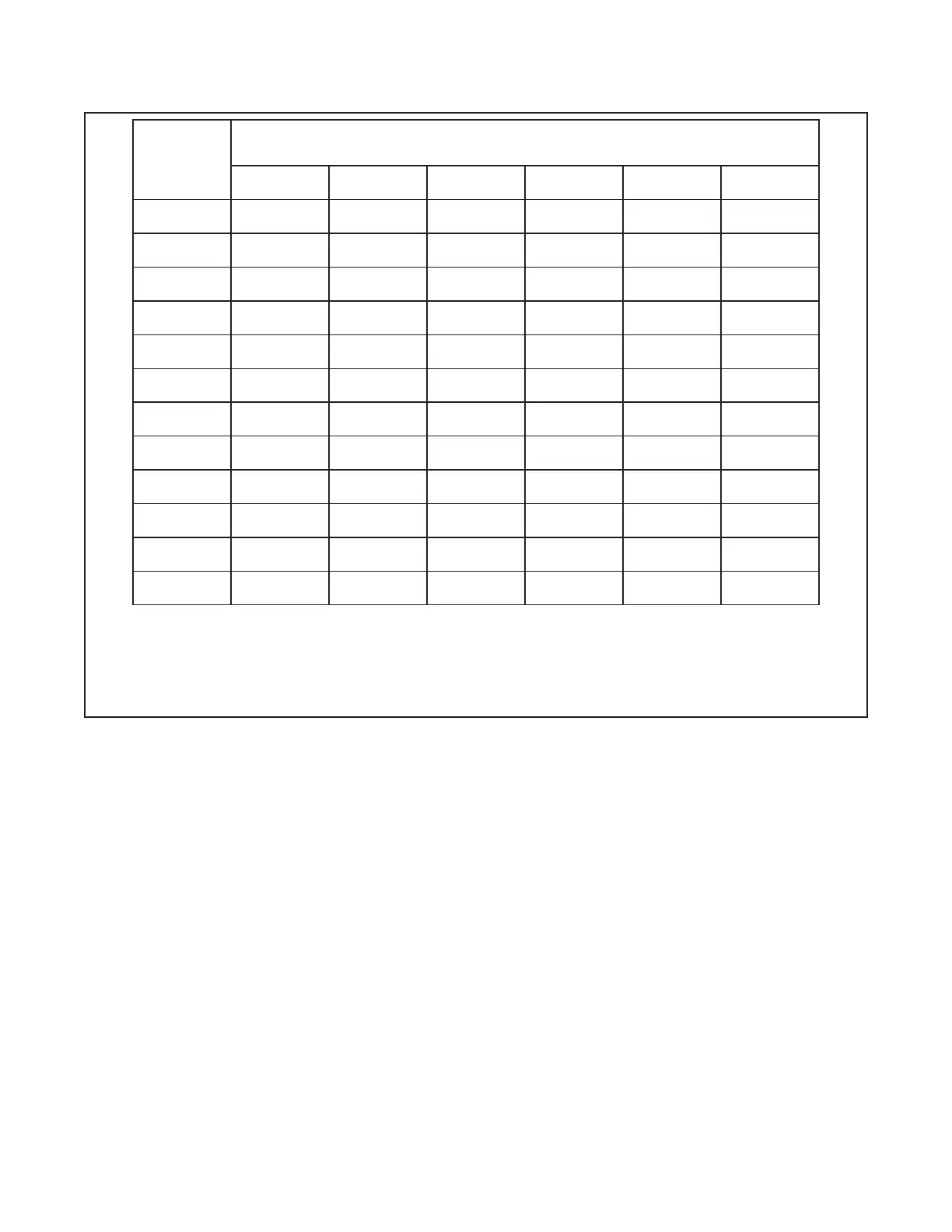

Supply

Pressure,

(1)

PSI

(Bar)

Maximum Pilot Height,

(2)

Feet

(Meters)

1-1/2"

(DN40)

2"

(DN50)

3"

(DN80)

4"

(DN100)

6"

(DN150)

8"

(DN200)

20

(1,4)

7

(1,4)

3

(0,9)

7

(1,4)

17

(5,2)

18

(5,5)

9

(2,7)

40

(2,8)

24

( 7,3)

19

(5,8)

30

(9,1)

39

(11, 9)

38

(11,6 )

38

(11,6 )

60

(4,1)

46

(14,0)

38

(11,6 )

52

(15,8)

54

(16,5)

56

(17,1)

44

(13,4)

80

(5,5)

58

(17, 8)

54

(16,5)

70

(21,3)

60

(18,3)

70

(21,3)

58

(17, 8)

100

(6,9)

78

(23,8)

78

(23,8)

93

(28,3)

78

(23,8)

99

(30,2)

65

(19,8)

120

(8,3)

87

(26,5)

87

(26,5)

117

(35,7)

115

(33,1)

130

(39,6)

96

(29,3)

140

(9,7)

105

(32,0)

107

(32,6)

139

(42,4)

142

(43,3)

154

(46,9)

141

(43,0)

160

(11,0 )

127

(38,7)

123

(37, 5)

161

(4 9,1)

176

(53,6)

161

(4 9,1)

170

(51,8)

175

(12,1)

134

(40,8)

138

(42,1)

172

(52,4)

171

(52,1)

194

(59,1)

194

(59,1)

200

(13,8)

160

(48,8)

160

(48,8)

206

(62,8)

223

(68,0)

216

(65,8)

206

(62,8)

225

(15,5)

185

(56,4)

166

(50,6)

237

(72,2)

233

(71,0)

246

(75,0)

250

(76,2)

250

(17, 2)

201

(61,3)

199

(60,7)

251

(76,5)

247

(75,3)

275

(83,8)

257

(78,3)

NOTES:

(1)

If supply pressure is variable, assume minimum expected value.

(2)

Maximum pilot height for up to 500 feet (150 meters) of equivalent length of pilot line (pipe plus ttings).

(3)

Interpolation between data points is permitted.

TABLE A

1-1/2 THRU 8 INCH (DN40 THRU DN200) DV-5 WET PILOT DESIGN CRITERIA FOR UP TO

500 FEET OF EQUIVALENT LENGTH OF PILOT LINE (PIPE PLUS FITTINGS)

Loading...

Loading...