TFP1410

Page 4 of 14

NOTICE

The DV-5 Supervised Single Interlock

Preaction System with Wet Pilot Actua-

tion Trim described herein must be in-

stalled and maintained in compliance

with this document, as well as with the

applicable standards of the National

Fire Protection Association, in addition

to the standards of any other authori-

ties having jurisdiction. Failure to do so

may impair the performance of the re-

lated devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Technical

Data

Approvals

UL and C-UL Listed

Deluge Valve

DV-5

Riser Check Valve

Model CV-1FR

NOTE: 1-1/2 inch (DN40) risers utilize

a 2 inch (DN50) Model CV-1FR Riser

Check Valve connected to the 1-1/2

inch (DN40) DV-5 Deluge Valve by a

2 x 1-1/2 inch Figure 716 Reducing

Coupling.

Valve Trim

The Supervised Single Interlock Pre-

action System with Wet Pilot Actuation

Trim (Fig. 3A or 3B) forms a part of the

laboratory listings and approvals. The

trim is necessary for proper operation

of the DV-5 Valve.

Each package of trim includes the fol-

lowing items:

• Water Supply Pressure Gauge

• Diaphragm Chamber

Pressure Gauge

• Diaphragm Chamber Connections

• Manual Control Station

• Main Drain Valve

• System Drain Valve

• Alarm Test Valve

• Automatic Drain Valve

• System Air Pressure Gauge

• Air Supply Connections

•

Low Air Pressure Supervisory Switch

•

Waterow Pressure Alarm Switch

(PS10-2)

The following items are included in the

Pre-trimmed Valve Assembly and can

be ordered separately for the valve

trim:

• Model BFV-N Buttery Valve

• Figure 577 Grooved Coupling

To ease eld assembly of the trim ar-

rangement, the trim components are

provided partially assembled as shown

in Figure 3B.

The trim arrangement is provided with

galvanized or black nipples and ttings.

The galvanized trim is intended for

non-corrosive or corrosive conditions,

whereas the black trim is principally in-

tended for use with AFFF systems.

NOTE: When the system pressure is

greater than 175 psi (12,1 bar), provi-

sion is to be made to replace the stan-

dard order 300 psi (20,7 bar) Water

Pressure Gauges, shown in Figure 3A

or 3B with separately ordered 600 psi

(41,4 bar) Water Pressure Gauges.

Detection System

In order for a single interlock preaction

system to be hydraulically calculated

as a wet pipe system, as opposed to a

dry pipe sprinkler system, the detection

system must be designed to operate

sooner than the automatic sprinklers

on the sprinkler piping. In the case of

wet pilot actuation, the system design-

er selects pilot sprinklers that will op-

erate sooner than the automatic sprin-

klers chosen for use on the sprinkler

piping.

The Supervised Single Interlock Pre-

action System with Wet Pilot Actua-

tion Trim provides for connection of a

detection system consisting of Wet Pi-

lot Line Sprinklers (heat detectors) and

manual control stations interconnected

with minimum 1/2 inch (DN15) Sched-

ule 40 steel pipe. The pilot line is con-

nected to the Wet Pilot Detection con-

nection shown in Figure 3B. Nominal

installation dimensions for the Super-

vised Single Interlock Preaction Sys-

tem with Wet Pilot Actuation Trim are

shown in Figure 4.

Wet pilot sprinklers are to be minimum

5.6 K-factor orice listed or approved

automatic sprinklers. Manual Control

Stations are to be the Model MC-1

described in Technical Data Sheet

TFP1382.

The maximum height of a wet pilot line

above the DV-5 Valve must not exceed

the limitations shown in Table A as a

function of the minimum water sup-

ply pressure to the DV-5 Valve for an

equivalent length (pipe plus ttings) of

the pilot line up to 500 feet to the most

remote pilot sprinkler.

Provision must be made for installing

a 5.6 K-factor orice, Inspector’s Test

Connection at the most hydraulically

demanding location of a wet pilot line

(usually adjacent to the highest and

most remote wet pilot line sprinkler or

manual control station).

Continued on Page 10

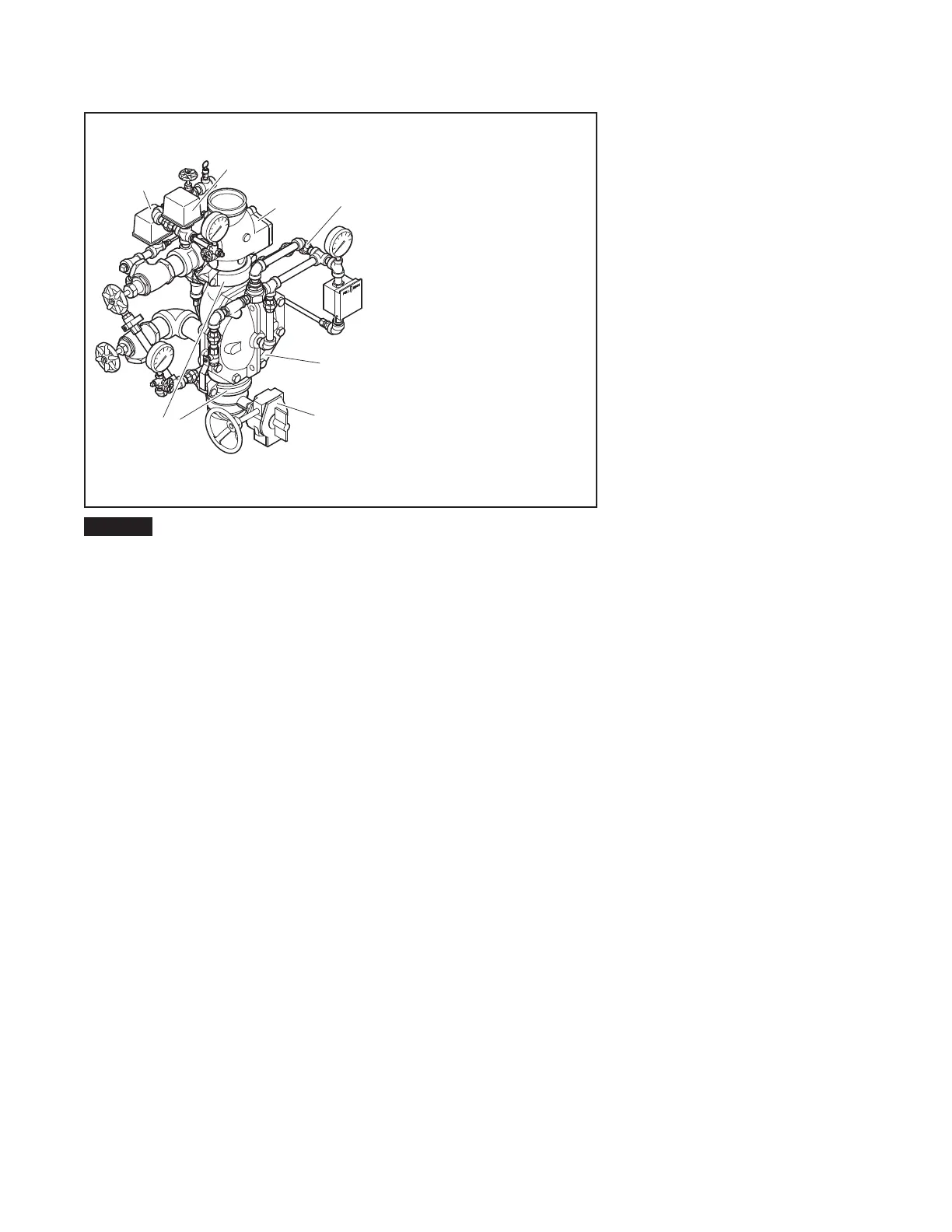

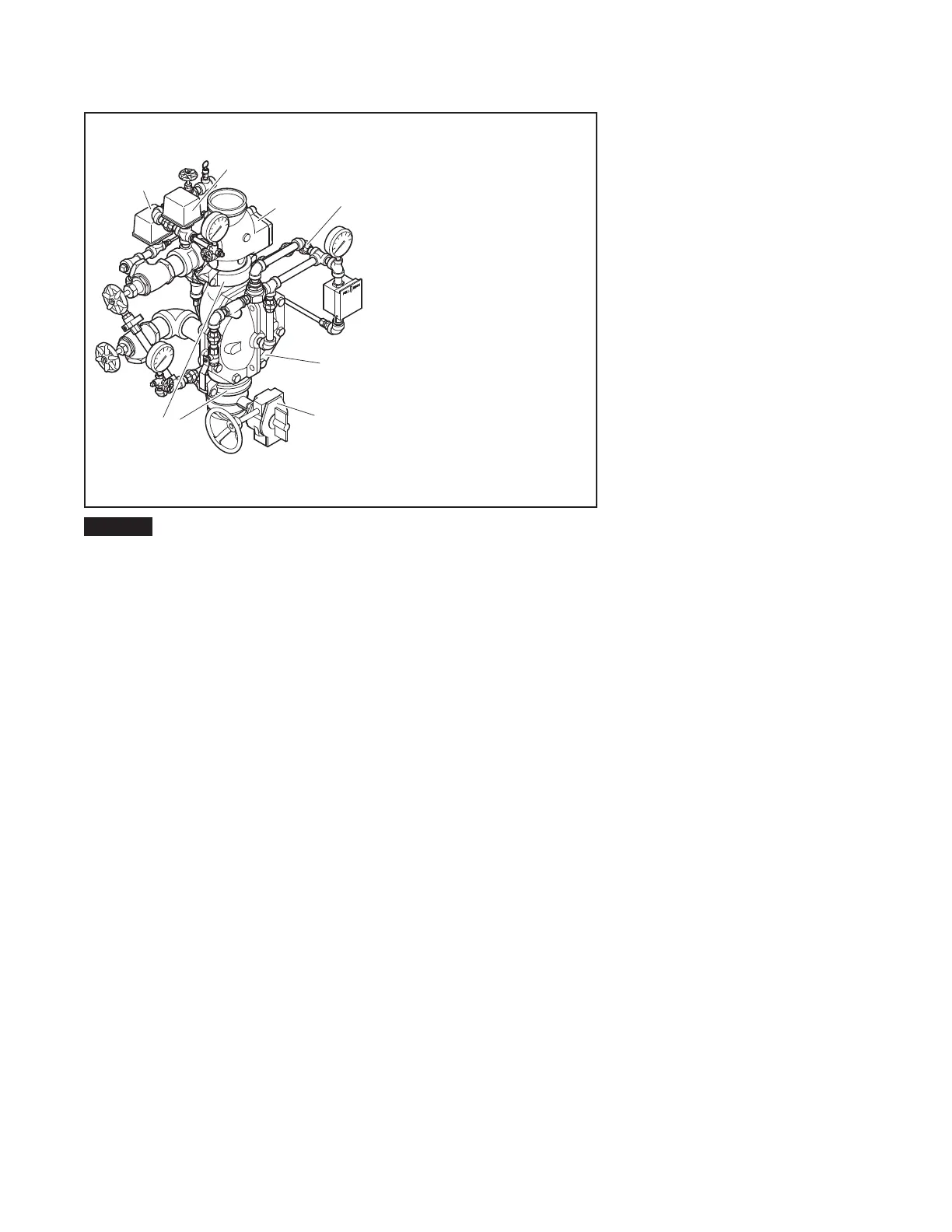

NOTES:

1. SEE FIGURE 3, PER VALVE SIZE

AS APPLICABLE, FOR TRIM

ARRANGEMENT WITH BILL OF

MATERIALS AND COMPONENT

PART NUMBERS.

TRIM SHOWN FULLY ASSEMBLED;

COMPONENTS SUCH AS GAUGES

AND SWITCHES MAY REQUIRE

ASSEMBLY IN TRIM AT VALVE

INSTALLATION.

2.

DV-5

DELUGE

VALVE

WATERFLOW

PRESSURE

ALARM

SWITCH

SYSTEM

SHUT-OFF

VALVE

PREACTION

SINGLE

INTERLOCK

WET PILOT

ACTUATION

TRIM

GROOVED

COUPLING

PRESSURE

ALARM

SWITCH

CHECK

VALVE

FIGURE 2

DV-5 PRE-TRIMMED SUPERVISED SINGLE INTERLOCK

PREACTION SYSTEM, WET PILOT ACTUATION

Loading...

Loading...