TECHNICAL DATA

Deluge Valve:

The 4 and 6 inch (100 and 150 mm),

Model F470H Horizontal Multimatic

Deluge Valves are rated for use at a

maximum service pressure of 175 psi

(12,1 bar). The Valve dimensions are

shown in Figure A, and all of the ports

are NPT threaded per ANSI Standard

B1.20.1. Flanged inlet and outlet con-

nections are available drilled per the

ANSI, AS, ISO, and JIS specification

options indicated in Table A. When the

flange drilling is provided to AS, ISO,

or JIS specifications, the label located

on the Handhole Cover indicates the

specification to which the flange drill-

ing has been provided.

The F470H Valve is to be installedhori-

zontally, as shown in Figure A.Exterior

surfaces of the F470H Valve are

painted red, and the year of manufac-

ture is indicated on the Handhole

Cover.

Components of the F470H Valve are

shown in Figure B. The Body, Hand-

hole Cover, and Diaphragm Cover are

ductile iron per ASTM A536 (UNS

F33100). The Handhole Cover Gasket

is neoprene, and the Clapper Facing,

Diaphragm, and O-Rings are EPDM.

The Seat Ring, Clapper, Diaphragm

Retainer, and the Flange of the Flange

& Push Rod Assembly are bronze per

ASTM B62 (UNS C83600).The Clap-

per Latch is aluminum bronze per

ASTM B148 (UNS C956200), the

Clapper Latch Stop is brass per ASTM

B16 (UNS C36000), and the Bearings

are bronze per ASTM B438, Grade 1,

Type II. The Clapper Facing Retainer,

Clapper Bolt, Clapper Hinge Pin, Latch

Hinge Pin, and the Push Rod of the

Flange & Push Rod Assembly are fab-

ricated from austenitic stainless steel.

The Handhole Cover Bolts, Diaphragm

Cover Bolts, and Pipe Plugs are carb-

on steel.

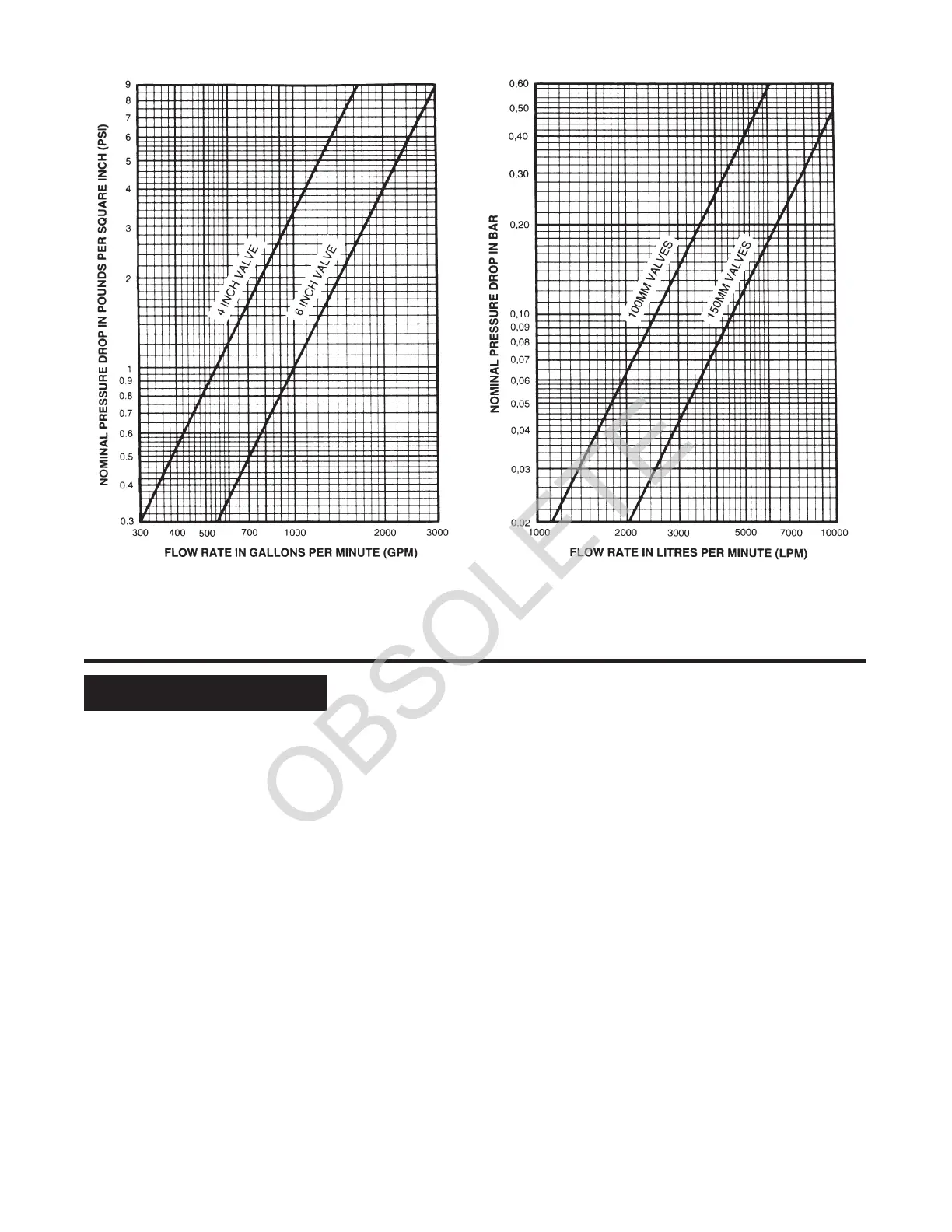

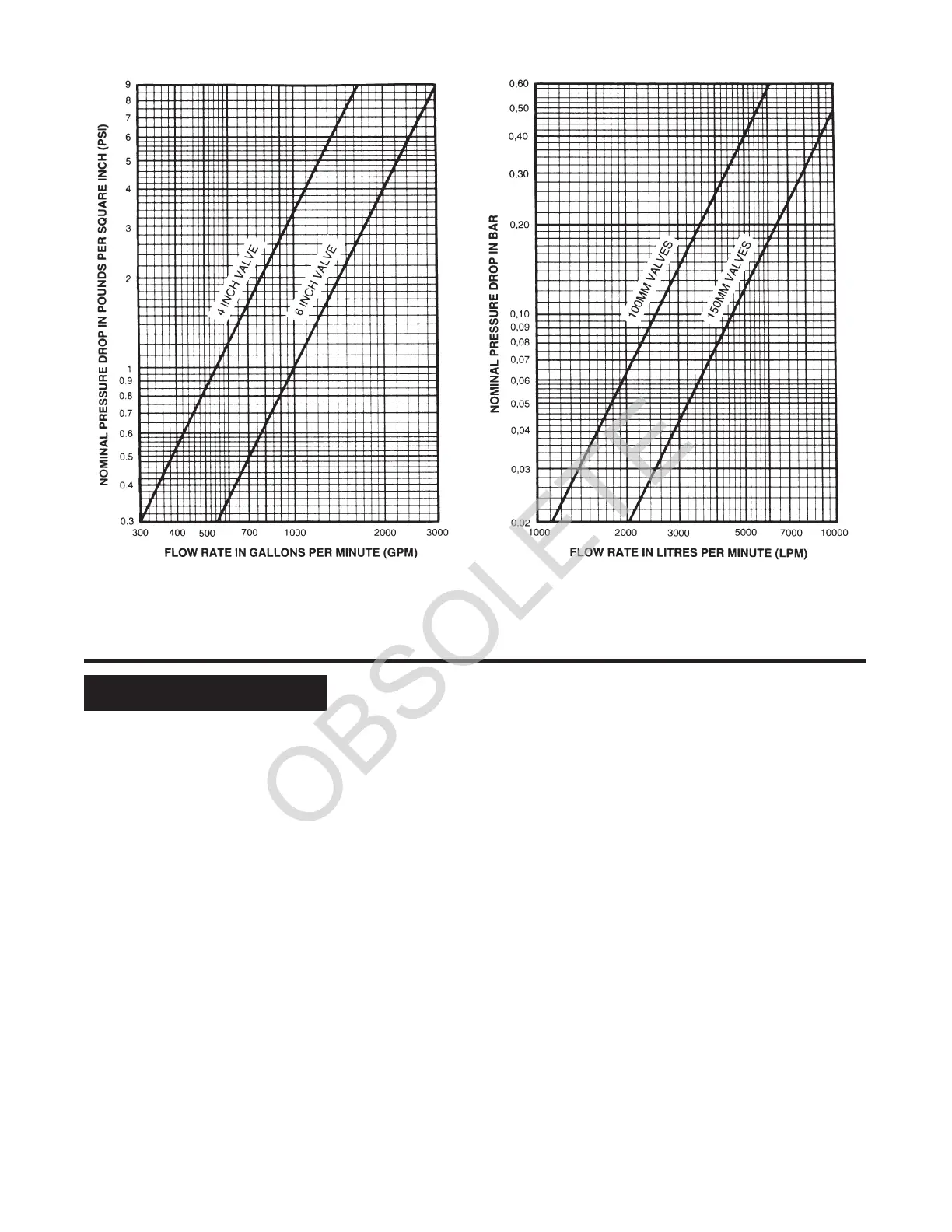

The nominal pressure losses versus

flow are shown in Graphs A-1 and A-2.

The approximate friction losses, based

on the Hazen and Williams formula

and expressed in equivalent length of

Schedule 40 pipe with C = 120, is 12

feet for the 4 inch (100 mm) valve size

and 30 feet for the 6 inch (150 mm)

valve size. The equivalent length of

pipe has been calculated on the basis

of the flow rates typically used with

each size valve.

Valve Trim:

The Wet Pilot Actuation Trim, Dry Pilot

Actuation Trim, or Electric Actuation

Trim illustrated in Figure D form a part

of the laboratory listings and approval

of the F470H Valves and are neces-

sary for their proper operation. Each

package of trim includes the following

items:

• Water Supply Pressure Gauge

• Diaphragm Chamber

Pressure Gauge

• DiaphragmChamber Connections

• Actuation Devices (as applicable)

• Main Drain Valve

• Alarm Test Valve

• Alarm Control Valve

• Automatic Drain Valve

• Dry Pilot Line Pressure Gauge

(as applicable)

Wet Pilot Actuation

(Figure D, Items 1 through 38)

The Wet Pilot Actuation Trim provides

for connection of a detection system

consisting of wet pilot sprinklers (heat

detectors) and manual control stations

-3

GRAPHS A-1 and A-2

NOMINAL PRESSURE LOSS VERSUS FLOW

GRAPH A-1 GRAPH A-2

Loading...

Loading...