which holds the Clapper down in the

set position is reduced to below the

valvetrippoint.

Dry pilot sprinklers are to be minimum

1/2 inch (15 mm) orifice listed or ap-

proved automatic sprinklers. Manual

Control Stations are to be either the

Model F180 or F184 described in Tech-

nical Data Sheet TD121.

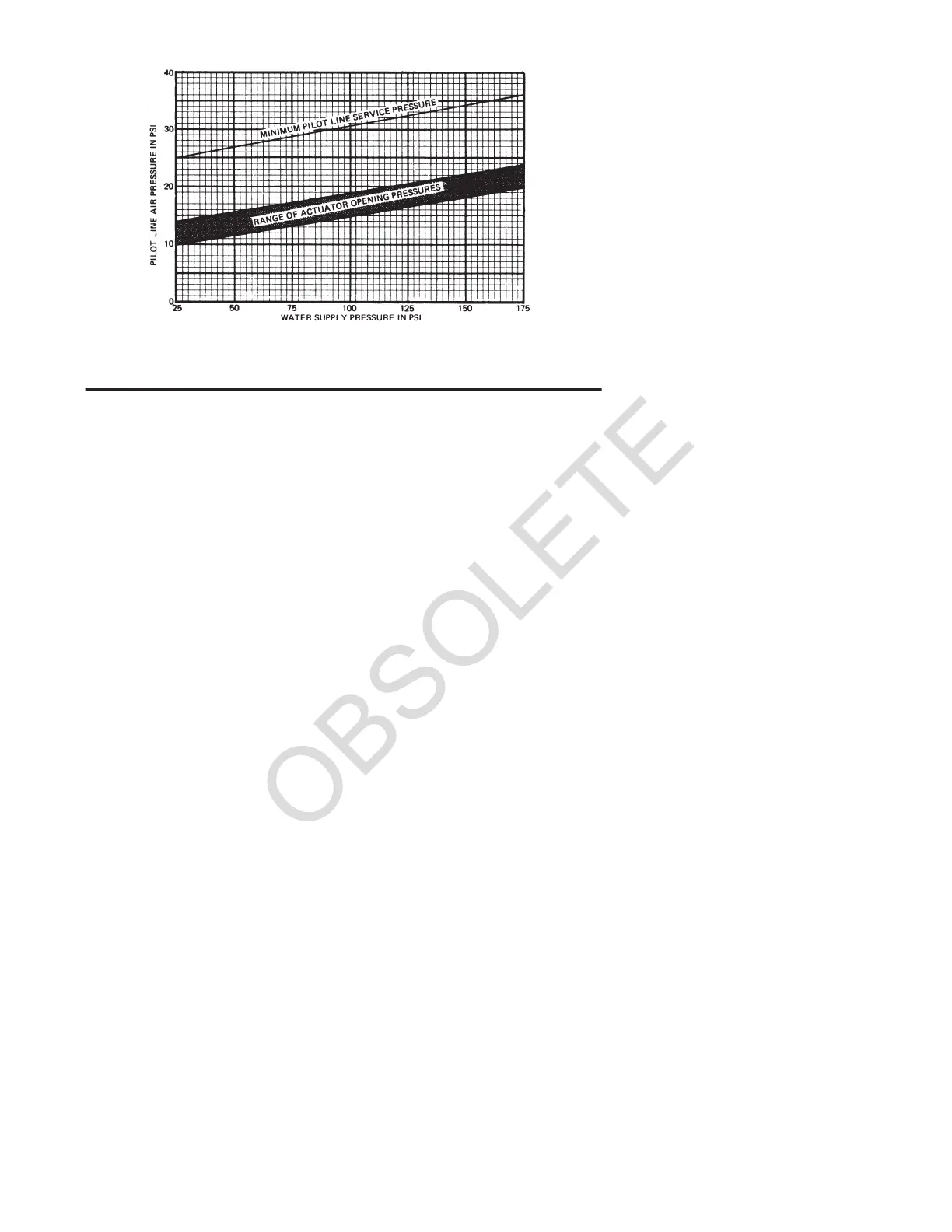

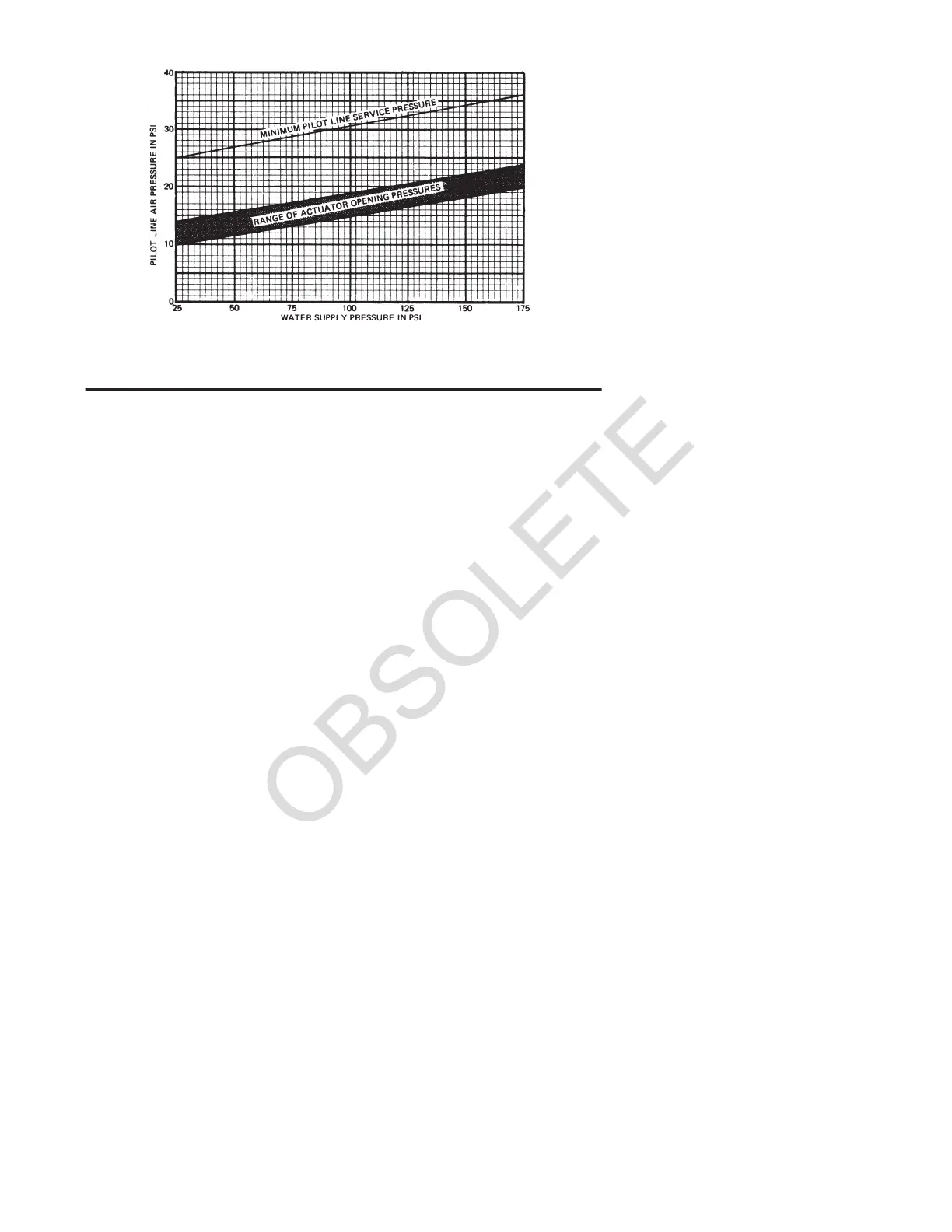

Graph C shows the “minimum pilot line

service pressure” as a function of the

water supply pressure.The pressure in

the dry pilot actuation system must be

automatically maintained using one of

the following maintenance devices, as

appropriate.

• Model F324 Air Maintenance De-

vice (pressure reducing type), re-

fer to Technical Data Sheet

TD111.

• Model F326 Air Maintenance De-

vice (compressor control type), re-

fer to Technical Data Sheet

TD112.

• Model F328 Nitrogen Mainte-

nance Device (high pressure re-

ducing type), refer to Technical

Data Sheet TD113.

NOTES

The dewpointof thepilotlineair pres-

sure must be maintained below the

lowest ambient temperature to which

the dry pilot actuation system will be

exposed.Accumulation of water in the

pilot line connection to the Actuator

will lower the air pressure at which

the Actuator will open and possibly

prevent proper operation. Also, intro-

ductionofmoisture into thepilot lines

exposed to freezing temperatures can

createanice buildupwhichcouldpre-

vent proper operation of the Actuator.

An air dryer must be installed where

the moisture content of the air supply

is not properly controlled at less than

therequiredvalue.Thedesiccantdryer

with mounting accessories described

inTechnicalDataSheetTD135issuit-

able for use with a maximum inlet

pressure of 150 psi (10,3 bar) and for

drying system air down to a dewpoint

of less than -20°F/-29°C at a pressure

of 45 psi (3,1 bar).

It is recommended that an F328 Ni-

trogenMaintenanceDevicebe utilized

in dry pilot actuation system applica-

tions where the dewpoint must be

maintained below -20°F/-29°C. See

Technical Data Sheet TD113.

Itisrecommendedthatinternallygal-

vanized pipe and cast iron fittings be

used for dry pilot lines.

Supervision of the pressure in the dry

pilot actuation system and/or alarm

which separately indicates operation

of the detection system is recom-

mended and may be required by the

authority having jurisdiction. A dual

setting low pressure alarm switch,

such as the unit described in Technical

Data Sheet TD210, is suitable for the

service. The recommended pressure

settings are as follows:

• Low pressure alarm setting at

approximately 6 psi (0,4 bar)

below the minimum pilot line

service pressure requirement

shown in Graph C.

• Fire alarm setting at approxi-

mately 15 psi (1,0 bar) below

the minimum pilot line service

pressure requirement shown

in Graph C.

The Pressure Relief Valve (Ref. Item

D5 - Fig. D) is factory set to relieve at

a pressure of approximately 45 psi (3,1

bar); however, it may be field adjusted

to a lower pressure, if required.

Electric Actuation Trim

(Figure D, Items 1 through 38 plus

Items E1 through E5)

The Electric Actuation Trim is required

for electric operation of the F470H

Valve by a detection system consisting

of electrical devices such as heat sen-

sitive thermostats, smoke detectors,

and/or electric manual pull stations.

Information on the various types of So-

lenoid Valves that may be used with

this trim package is given in Technical

Data Sheet TD119. A listed and ap-

proved, 24VDC Solenoid Valve for

non-hazardous locations is supplied

as standard. Minimum clearance di-

mensions for the Electric Actuation

Trim are shown in Figure C.

NOTE

ApprovalbyFactoryMutualiscontin-

gent on the use of an FM Approved

24VDC Solenoid Valve. FM only ap-

proves solenoid valves for use in non-

hazardous locations.

The Electric Actuation Trim is only to

be used in conjunction with an electric

deluge valve releasing panel (auto-

matic control unit) that is listed or ap-

proved (as appropriate) for fire protec-

tion system releasing service. In

addition, the deluge valve releasing

panel is only to be operated by listed

or approved (as approriate) fire detec-

tors.

Operation of an electrical device such

as a heat sensitive thermostat, smoke

detector, or electrical manual control

station signals the deluge valve releas-

ing panel to energize the Solenoid

Valve. In turn, the energized Solenoid

Valve opens resulting in a rapid pres-

sure drop in the Diaphragm Chamber

of the F470H Valve, and the force dif-

ferential applied through the Clapper

Latch which holds the Clapper down in

the set position is reduced to below the

valvetrippoint.

NOTE

Consult with the Authority Having

Jurisdiction regarding installation

criteria pertaining to electric actua-

tion circuitry.

-5-

GRAPH C

DRY PILOT LINE PRESSURE REQUIREMENTS

Loading...

Loading...