-5-

1

2

3

1

2

7

8

9

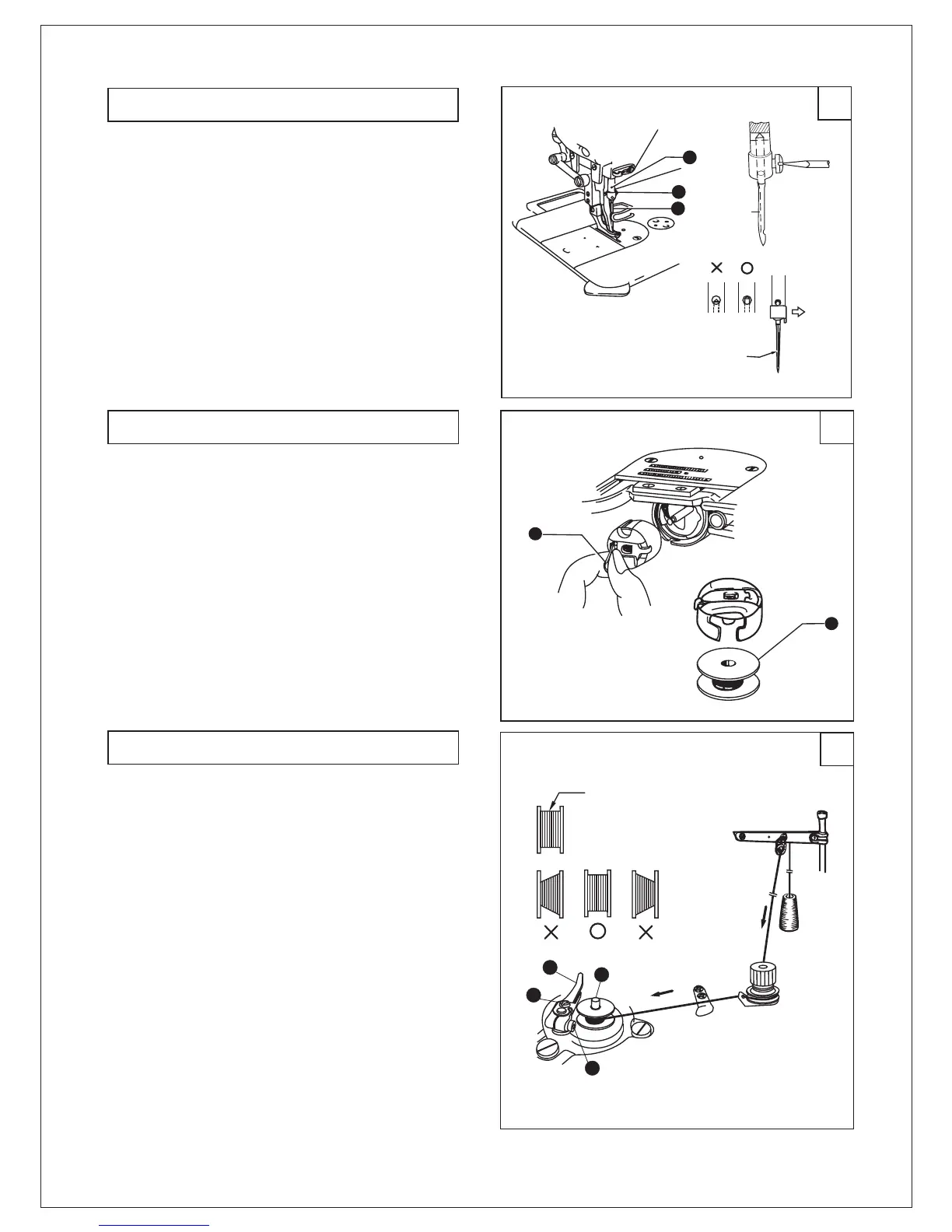

9. Installing the needle (Fig.7)

1.Turn the machine pulley to move the needle

bar ① to its highest position;

2.Loosen the screw ②

3.Insert the needle ③ in a straight line as far

as it will go, making sure that the long groove

on the needle is at the left, and then securely

tighten the screw ②

Groove leftward

Front

Long groove in needle

6

4

3

2

80%

Standard thread

winding amount

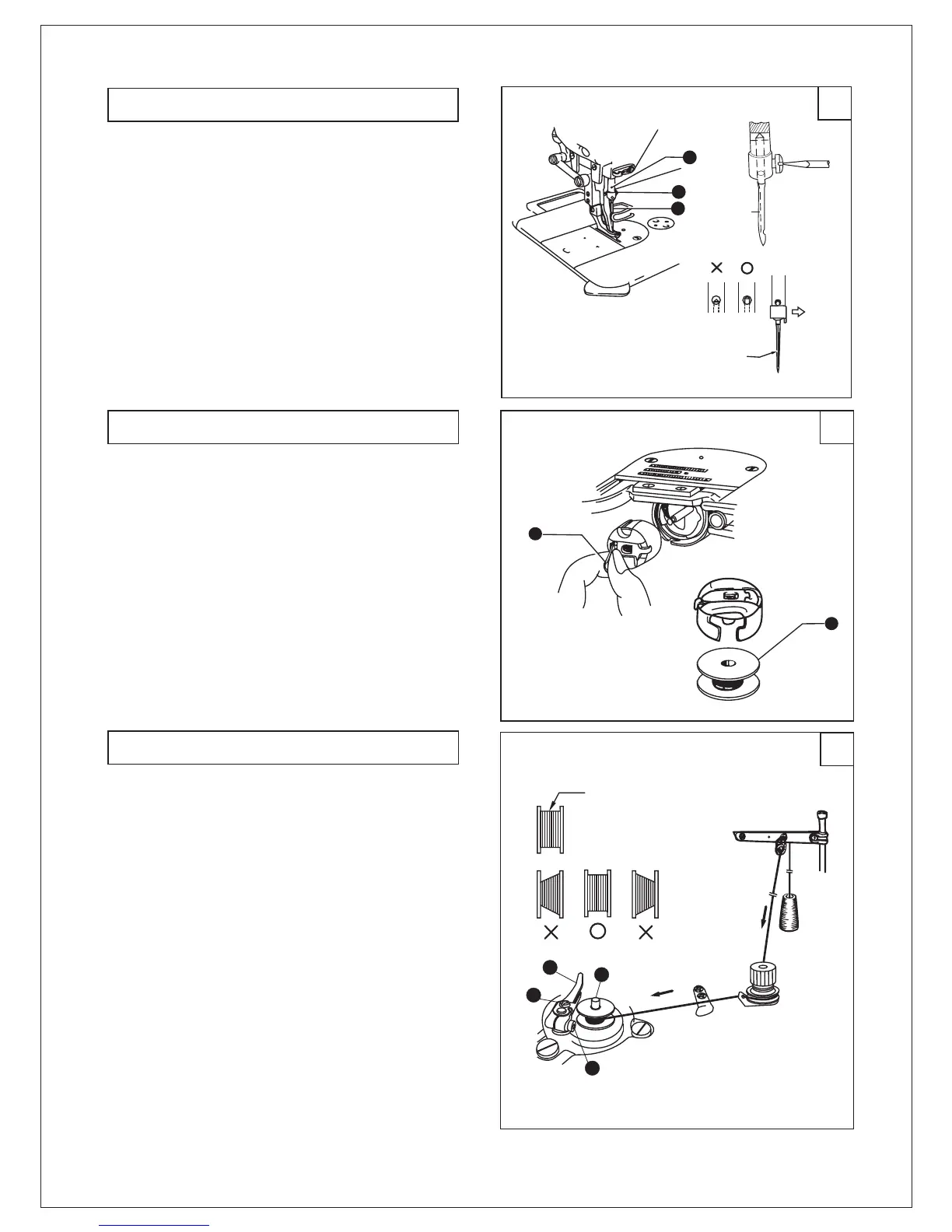

10. Removing the bobbin case(Fig.8)

1.Turn the machine pulley to lift the needle bar

to its highest position. Pull the latch ① of the

bobbin case upward and then put the bobbin

into the bobbin case, finally insert the complete

bobbin case with bobbin into the hook shaft.

2.To remove the bobbin case, pull the latch and

draw the bobbin case out of the hook.

11. Winding the bobbin thread (Fig.9)

1.Turn the power on;

2.Place the bobbin ① onto the bobbin winder

shaft ②;

3.Wind the thread several circles around the

bobbin in the direction indicated by arrow;

4.Push down the bobbin presser arm ③;

5.Lift the presser foot;

6.Depress the treadle, the winding operation

will start;

7.Once finished, the bobbin presser arm ③ will

recover automatically.

*If the thread winding is not neat and even,

loosen the screw ④ to adjust the position of

bobbin winder base.

*Turn the screw ⑥ to adjust the bobbin

winding amount

● Tighten the screw to increase the winding

amount;

● Loosen the screw to decrease the winding a

mount.

Note:

The proper winding amount should be around

80% of the bobbin capacity.

Loading...

Loading...