2

1

2

1

119.5

15

30

A

B

3

3. Installation and preparation

3.1 Installation

3.1.1 Location of the machine

To ensure a smooth running, the machine

of rubber mat between machine stand and floor is

recommended for further reducing the running

noise and vibration.

Should be located on rigid and flat floor.The insert

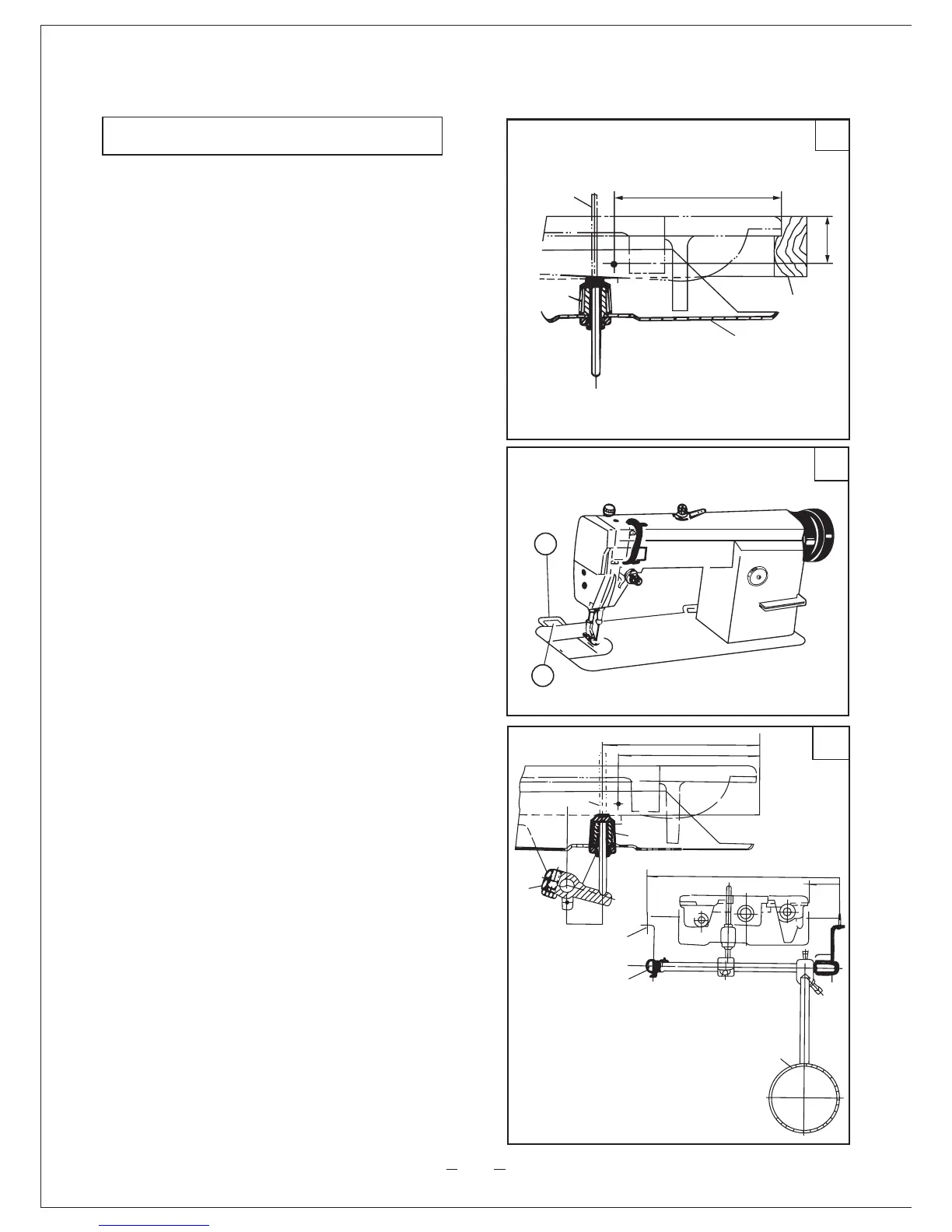

3.1.2 Installing drip pan(Fig.1)

Fix drip pan 1into the table cutout, aligning

rod 15 of machine head, and to touch it, also

maintain dimendions 30 and 119.5mm from nail

hole to the table, then drive nails into both

sides of the cutout to secure the drip pan.(further

see figure on page56).

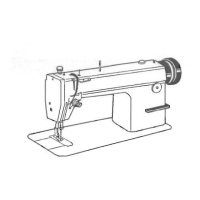

3.1.3 Mounting machine head(Fig.2)

Make the hinge A of machine head engaged

with hinge socket B on the table, then turn the

machine head freely till it is seated on the frame

of table cutout.

knee lifter lifting rod 3 with knee lifter connecting

3

268

132.5

119.5

15

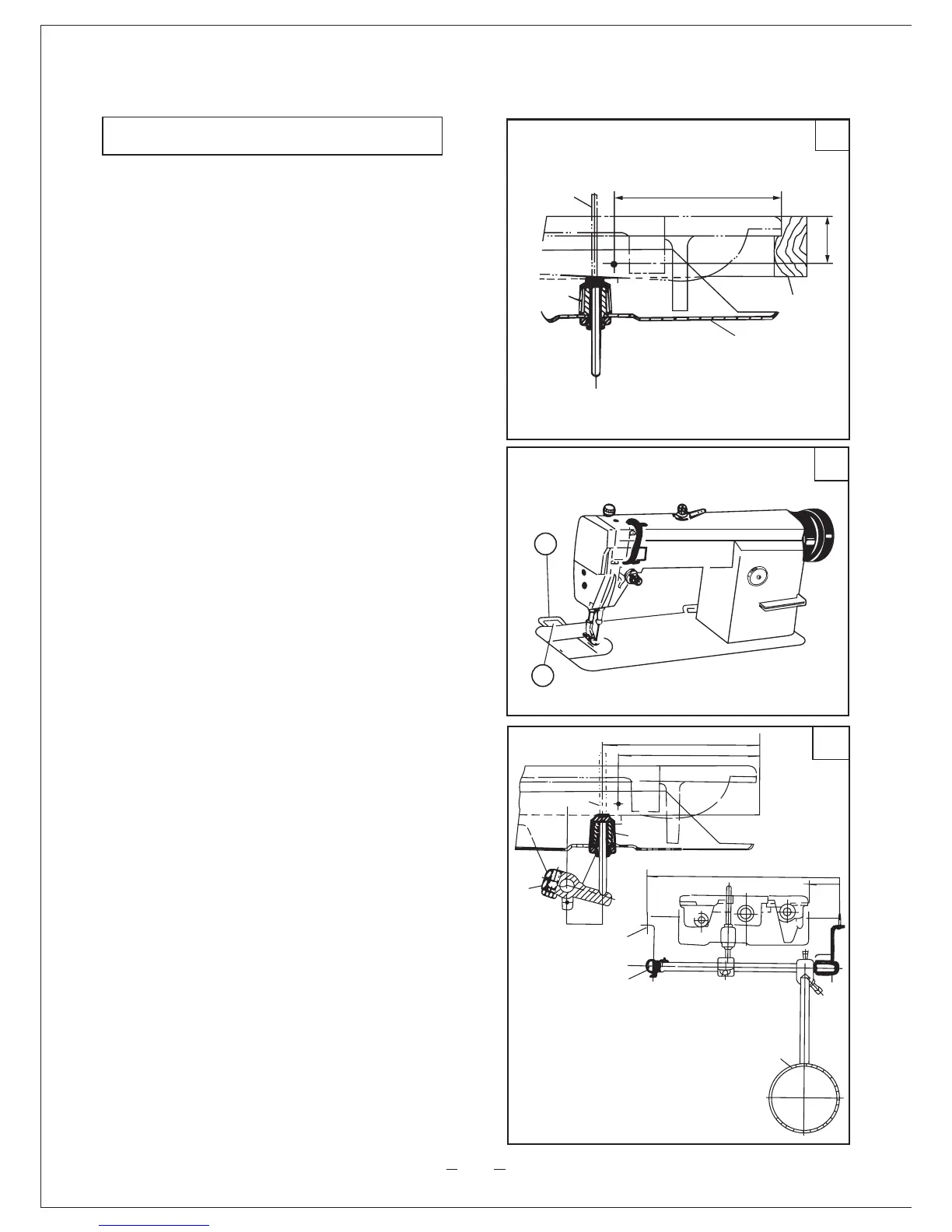

3

11

29

6

7

18

3.1.4 Mounting rock shaft bracket of knee liter

(Fig.3, also see figure on page 56)

1) Adjust rock shaft knee plate 18 according to

the body of operator,for the convenience to operate.

2) Adjust the position of knee lifter assembly

according to Fig. 3, then fasten the rock shaft

bracket with wood screws 6.

Loading...

Loading...