A

B

C

G

F

E

D

C

B

A

10

~

12mm

20-30

4

5

3

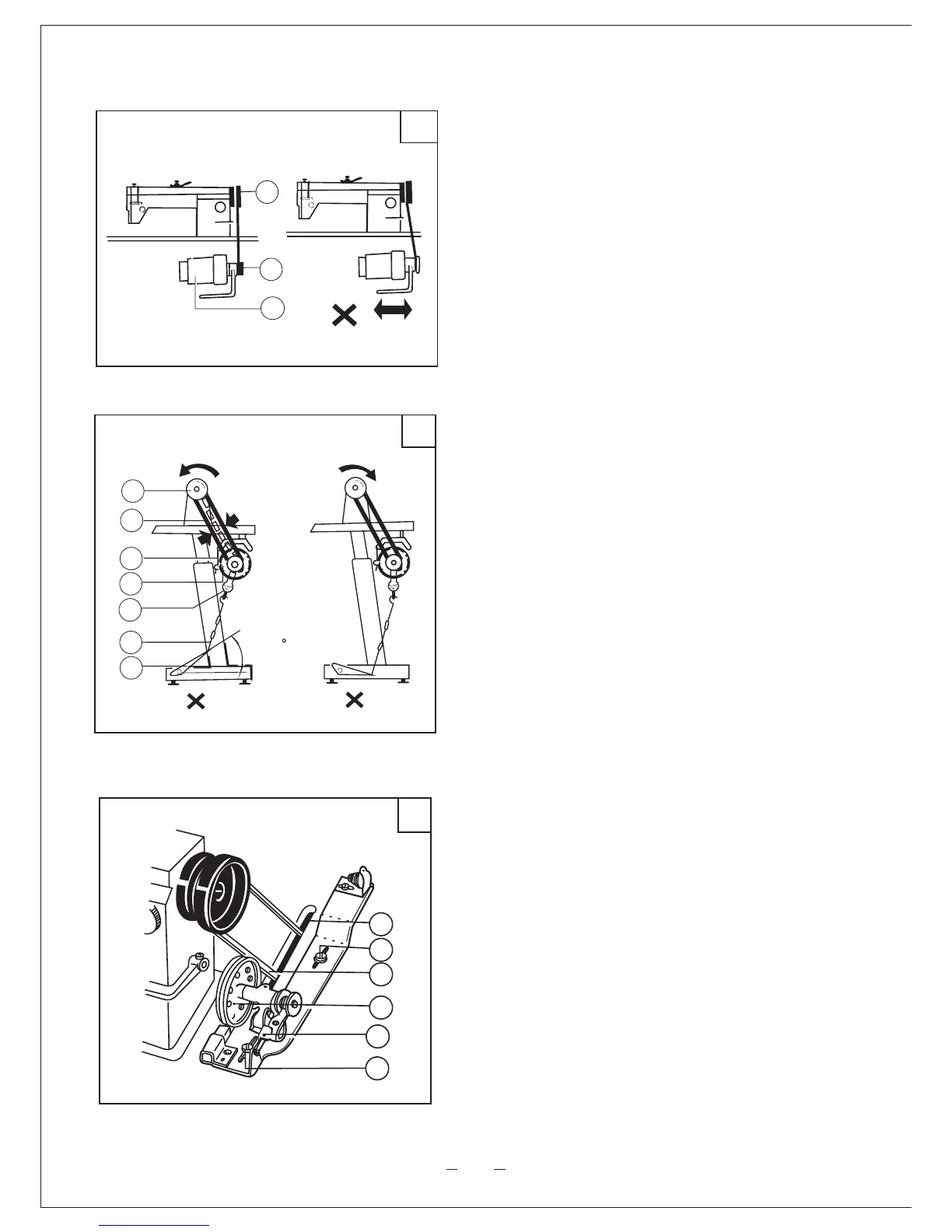

3.1.5 Installing the motor(Fig.4)

Align machin balance wheel belt groove A with

motor pulley belt groove B by moving the motor C

leftward or rightward. Be sure the belt is not touch

with table.

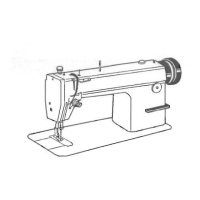

3.1.6 Connecting the clutch lever to the pedal (Fig.5)

1) The optimum tilt angle of pedal A with

floor is approx. 15 degree.

2) Adjust the clutch of the motor so that

clutch lever C and draw bar B run in line.

3) The machine balance wheel should rotate

counterclockwise for normal sewing when view

from opposite side of balance wheel G. The

motor is rotation in the same direction.The rotation

can be reversed by reversing (turn over 180 deg.)

The plug of motor.

4) Adjust the tension of V-belt F by moving

the motor vertically. The proper tension of V-belt

is a salck of 10-12mm when the belt is depressed

at the belt span by finger.

Correct

incorrect

6

A

B

C

D

D

E

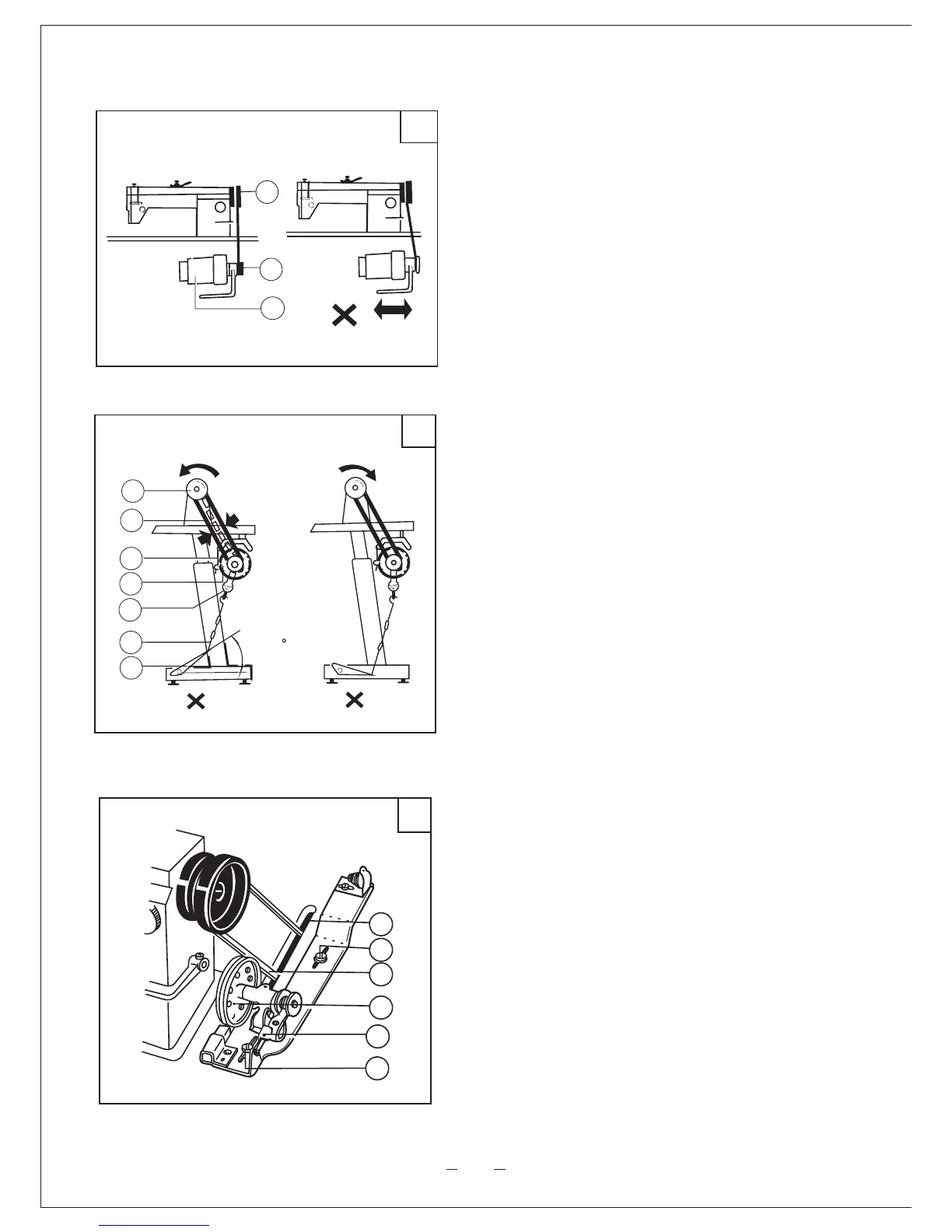

3.1.7 Installing the bobbin winder(Fig.6)

Align pulley B of bobbin winder with outside

of belt and should be kept a proper clearance

between them, so that pulley B could be contacted

with belt after the stop latch thumb.

lever A depressed, thereby belt drives the pulley

B while machine running. After check bobbin

winder is in parallel with belt slit E of table,

fastened by two wood screws D.

Loading...

Loading...