C

4

8A

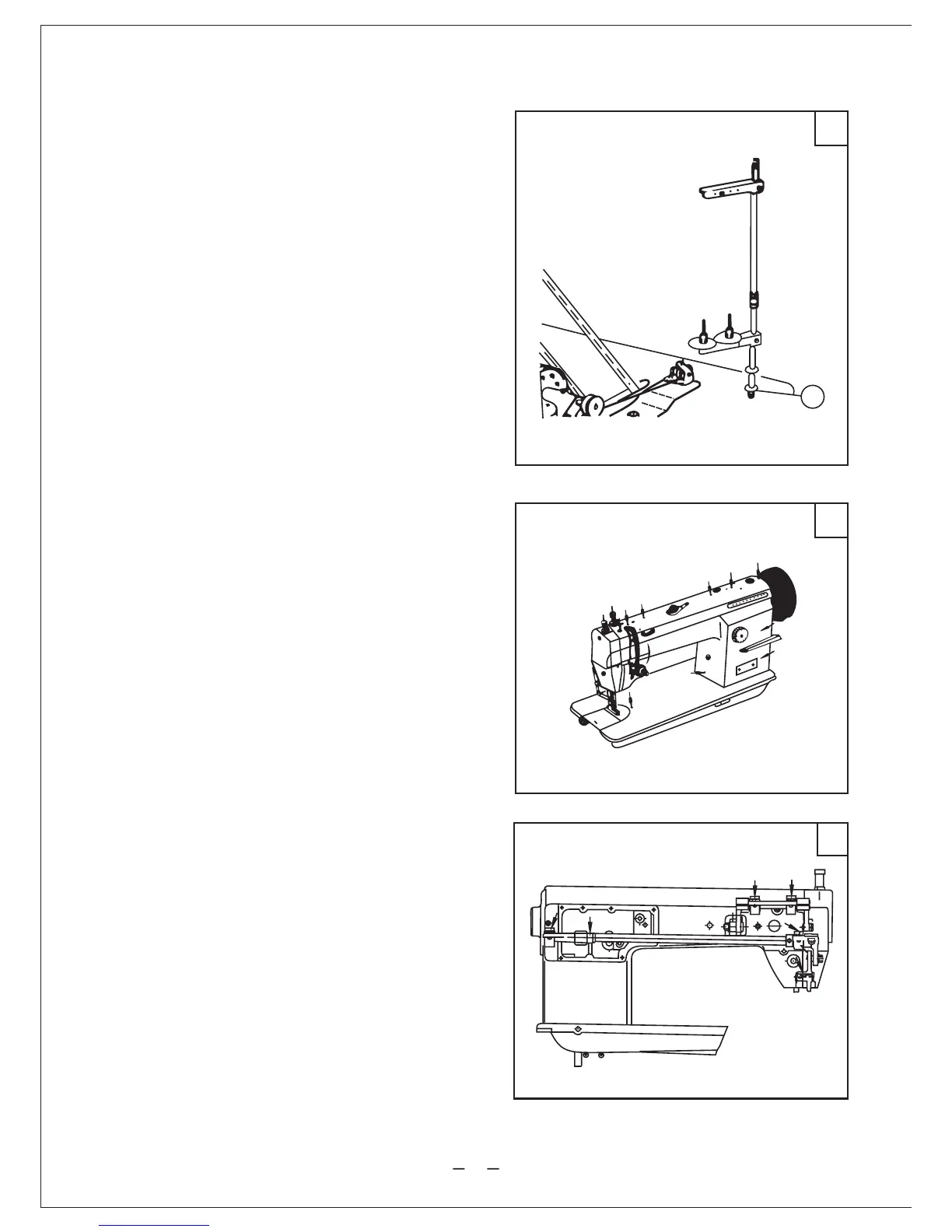

3.1.8 Installing the thread unwiner (Fig.7)

Locate thread unwinder at the right front of

the table, note that spool rest may not obstruct

when machine head is turned backward, then

tightern wood screw C.

3.2 Preparation

3.2.1 Cleaning the machine

Before delivery , the machine parts are

coated with rust preventive grease, which may be

hardened and contaminated by dust during storage

and shipment. This grease must be removed by

clean cloth with gasoline.

3.2.2 Examination

Though every machine is confirmed by strict

inspection and test before delivery,the machine parts

may be loosed or deformed after long distance

transportation with jolt. A thorough examination

must be performed after cleaning the machine.

Turn the balance wheel to see if there is running

obstruction, parts collision, uneven resistance or

abnormal noise. If these exist, adjustment must be

made accordingly before run.

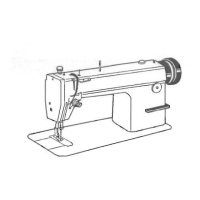

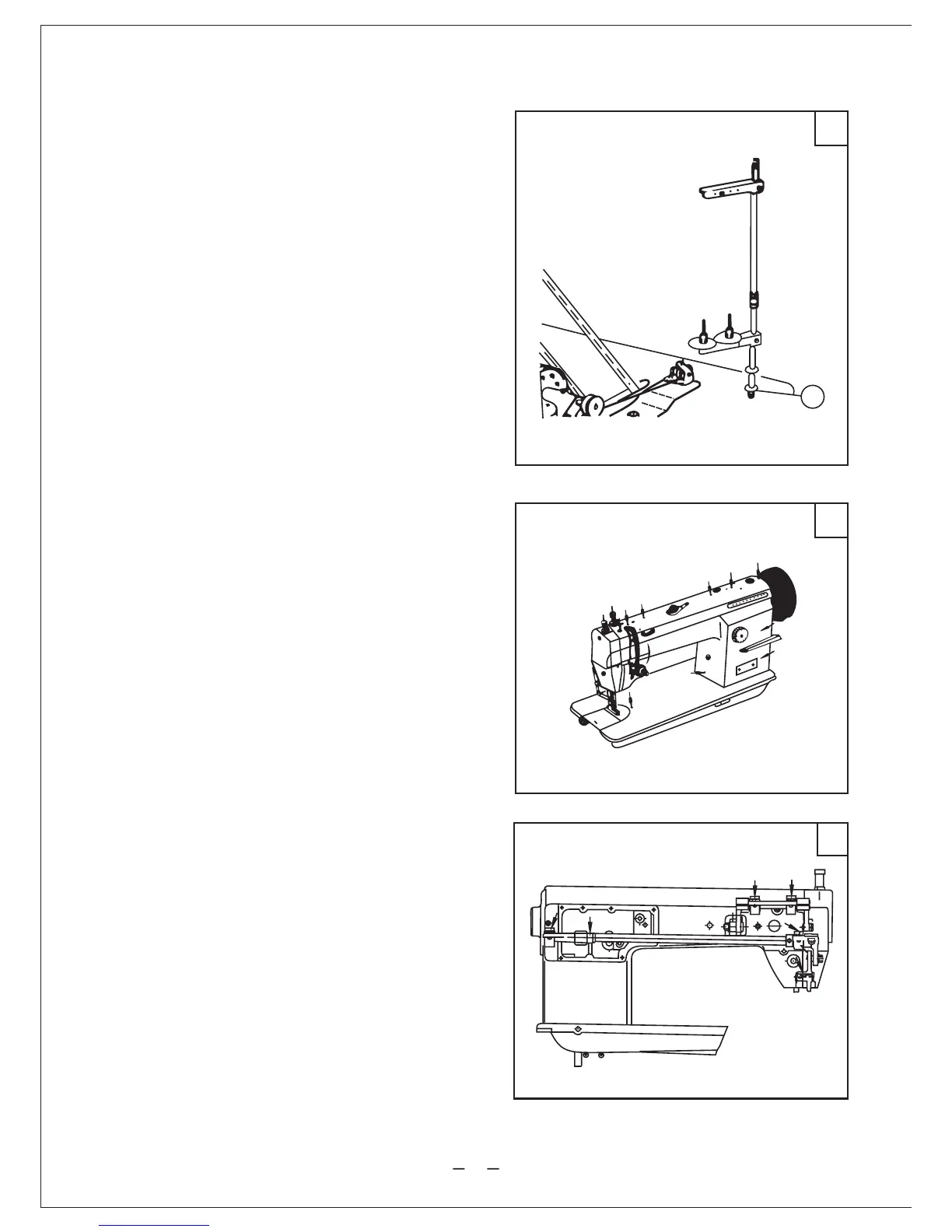

3.2.3 Lubrication

Before machine running, Clean it with soft

cloth, then fully lubricate the holes indicated by

arrows shown in Fig8 .

If the machine is in contionus operation, the

operator should lubricate it no less than two

times a days.

Be sure to use HA-8 Sewing Machine Oil

or HJ-7 Machinery Oil.

7

8B

Loading...

Loading...