USER GUIDE

Troubleshooting

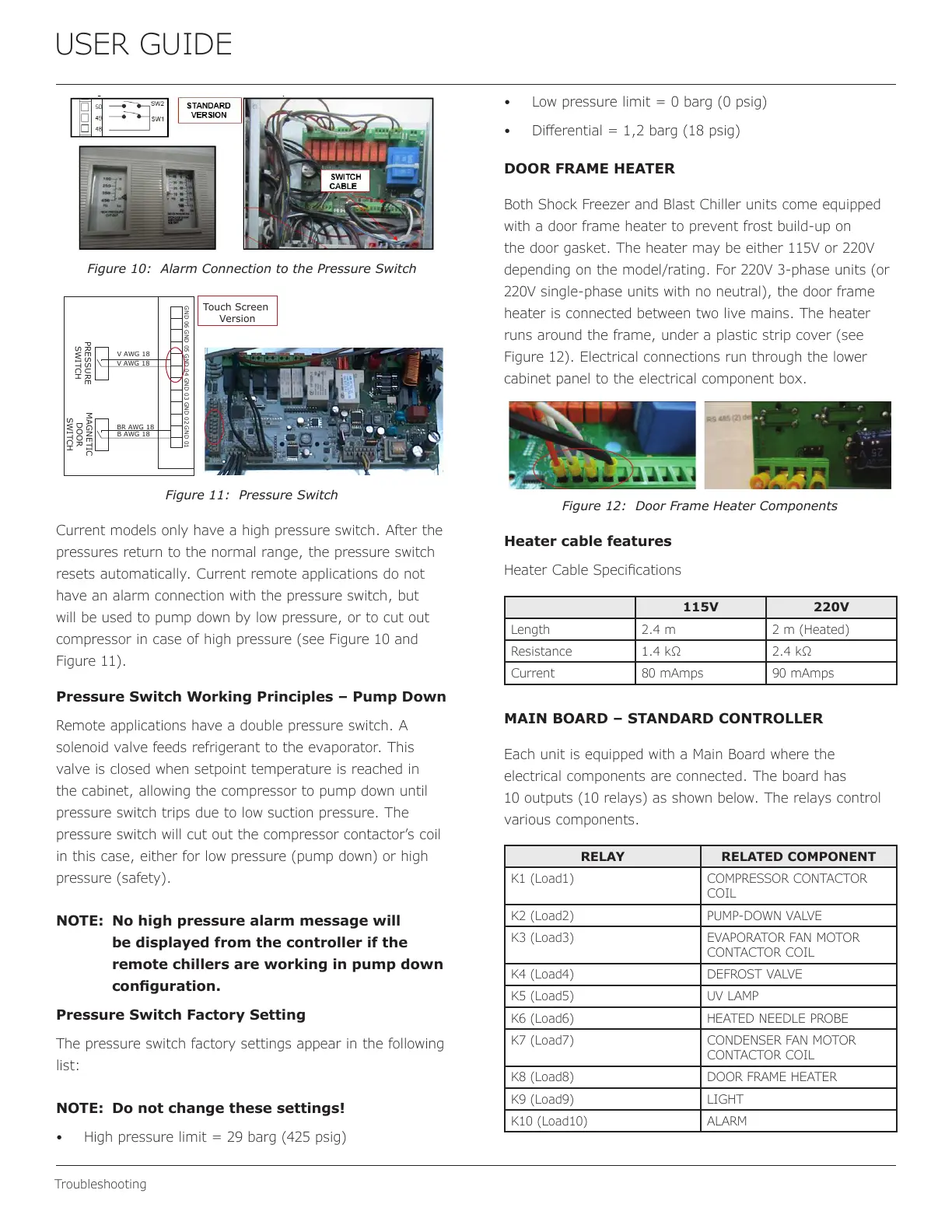

Figure 10: Alarm Connection to the Pressure Switch

V AWG 18

V AWG 18

BR AWG 18

B AWG 18

GND 04GND 06 GND 03 GND 01GND 02GND 05

PRESSURE

SWITCH

MAGNETIC

DOOR

SWITCH

Touch Screen

Version

Figure 11: Pressure Switch

Current models only have a high pressure switch. After the

pressures return to the normal range, the pressure switch

resets automatically. Current remote applications do not

have an alarm connection with the pressure switch, but

will be used to pump down by low pressure, or to cut out

compressor in case of high pressure (see Figure 10 and

Figure 11).

Pressure Switch Working Principles – Pump Down

Remote applications have a double pressure switch. A

solenoid valve feeds refrigerant to the evaporator. This

valve is closed when setpoint temperature is reached in

the cabinet, allowing the compressor to pump down until

pressure switch trips due to low suction pressure. The

pressure switch will cut out the compressor contactor’s coil

in this case, either for low pressure (pump down) or high

pressure (safety).

NOTE: No high pressure alarm message will

be displayed from the controller if the

remote chillers are working in pump down

conguration.

Pressure Switch Factory Setting

The pressure switch factory settings appear in the following

list:

NOTE: Do not change these settings!

• High pressure limit = 29 barg (425 psig)

• Low pressure limit = 0 barg (0 psig)

• Dierential = 1,2 barg (18 psig)

DOOR FRAME HEATER

Both Shock Freezer and Blast Chiller units come equipped

with a door frame heater to prevent frost build-up on

the door gasket. The heater may be either 115V or 220V

depending on the model/rating. For 220V 3-phase units (or

220V single-phase units with no neutral), the door frame

heater is connected between two live mains. The heater

runs around the frame, under a plastic strip cover (see

Figure 12). Electrical connections run through the lower

cabinet panel to the electrical component box.

Figure 12: Door Frame Heater Components

Heater cable features

Heater Cable Specications

115V 220V

Length 2.4 m 2 m (Heated)

Resistance 1.4 kΩ 2.4 kΩ

Current 80 mAmps 90 mAmps

MAIN BOARD – STANDARD CONTROLLER

Each unit is equipped with a Main Board where the

electrical components are connected. The board has

10 outputs (10 relays) as shown below. The relays control

various components.

RELAY RELATED COMPONENT

K1 (Load1) COMPRESSOR CONTACTOR

COIL

K2 (Load2) PUMP-DOWN VALVE

K3 (Load3) EVAPORATOR FAN MOTOR

CONTACTOR COIL

K4 (Load4) DEFROST VALVE

K5 (Load5) UV LAMP

K6 (Load6) HEATED NEEDLE PROBE

K7 (Load7) CONDENSER FAN MOTOR

CONTACTOR COIL

K8 (Load8) DOOR FRAME HEATER

K9 (Load9) LIGHT

K10 (Load10) ALARM

37

Loading...

Loading...