IM 25.000AA UA (B/6-00)

CHLORINE HANDLING MANUAL

PAGE 4

Weight, Liquid

1 cf = 91.56 lb at 32° F.

Solubility in Water*

6.93 lbs./100 gals at 60° F and 1 atm.

Pressure vs Temperature

See Figure 1

*

NOTE: Theoretical values shown. Actual solubility in

water based on chlorinator performance has proven to be

3500 ppm or 2.92 lbs/100 gals maximum.

Chlorine is an oxidizing agent and will support combustion

but is not explosive or flammable. Many organic chemicals

will react with chlorine, some violently. Steel will ignite

spontaneously in the presence of chlorine at 483° F.

3 SUPPLY CONTAINERS

Table 1 gives details on the supply containers most com-

monly used with USF/W&T equipment.

Some large installations that would normally use single unit

tank cars but are not serviced by railroad facilities use tank

motor vehicles (tank trailers) which usually range in capacity

from 15 to 22 tons.

All supply containers must conform to appropriate Depart-

ment of Transportation (DOT) and Canadian Transport

Commission (CTC) regulations. It is the responsibility of the

supply container manufacturer and the chlorine supplier to

meet these requirements.

3.1 RATES

In general, using a remote vacuum type chlorinator, the maxi-

mum sustained gas withdrawal rate at which chlorine may be

taken from a 100 or 150 pound cylinder is one pound per day

per degree Fahrenheit (1.0 lb/24 hrs/°F). The corresponding

rate for ton containers is about 8.0 lbs/24 hrs/°F. At an as-

sumed liquid temperature of 70° F (and using a remote vacuum

type chlorinator) the above figures translate into 70 lbs/24

hrs for cylinders and 560 lbs/24 hrs for ton containers. For

a direct feed cylinder pressure operated chlorinator these

rates become 42 and 336 lbs/24 hrs respectively. These rates

can be increased substantially for brief periods. Do not place

containers in a water bath or apply direct heat in order to

permit higher withdrawal rates.

It is not practical to withdraw chlorine as a gas from tank cars

(or tank trailers).

3.1.1 MANIFOLDING FOR GAS WITHDRAWAL

When higher gas withdrawal rates are required, cylinders or

the gas valves (upper) of ton containers may be manifolded.

A typical arrangement for manifolding cylinders is shown in

Figure 2.

If cylinders or ton containers are manifolded, it is essential

that all supply containers be at the same temperature to pre-

vent the transfer of liquid chlorine from a warmer container

to a cooler container, possibly resulting in a container be-

coming overfilled through reliquefaction of chlorine in the

cooler container.

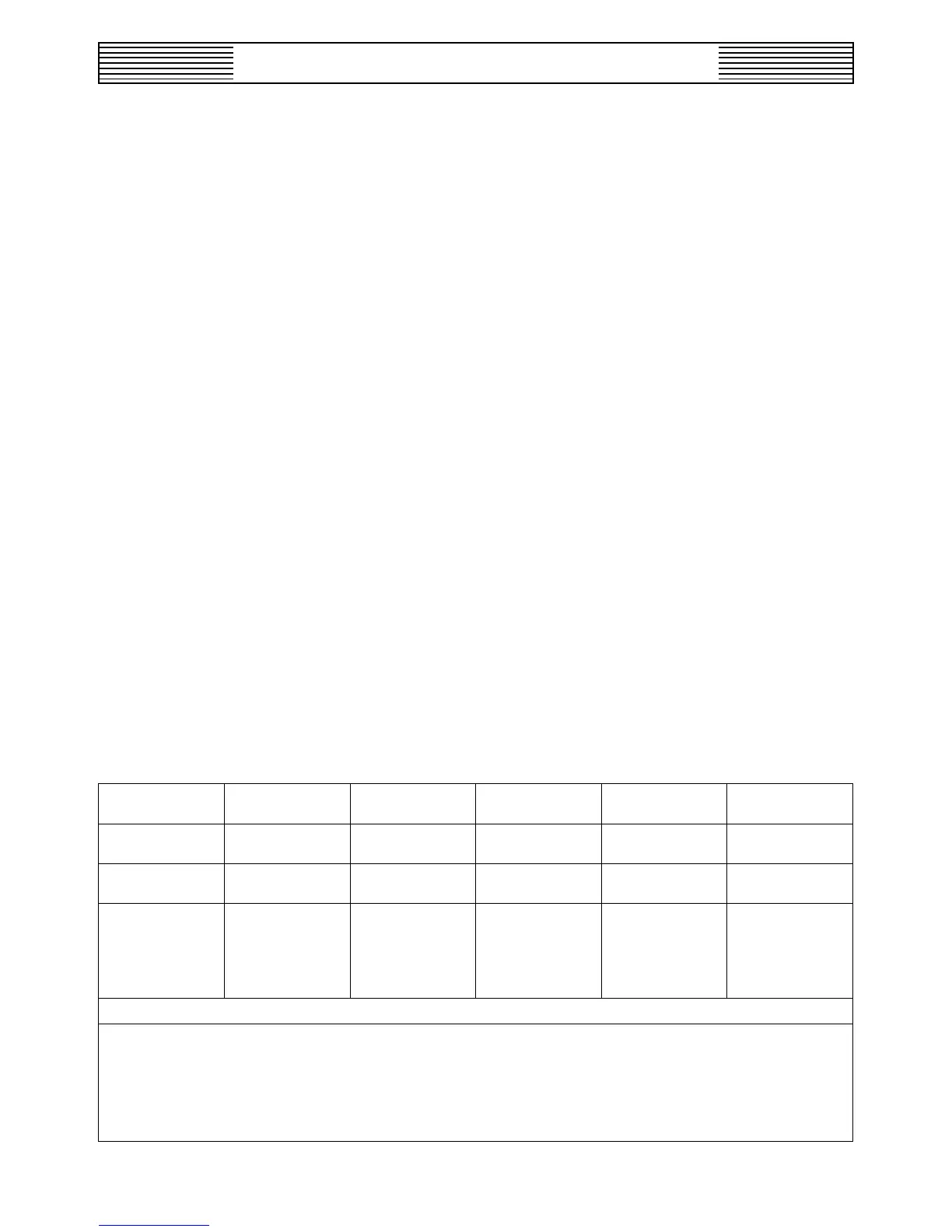

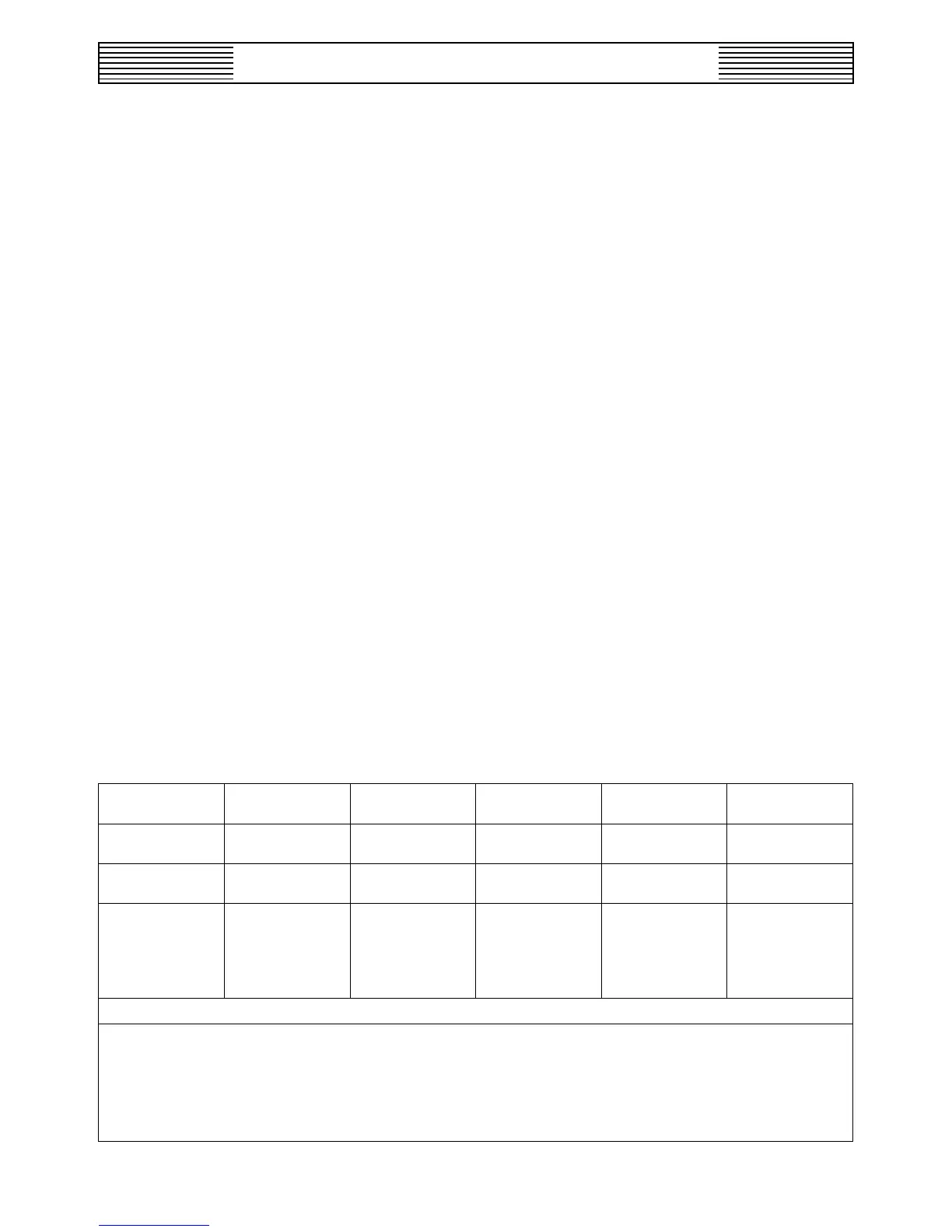

NOITAMROFNIRENIATNOCENIROLHC-1ELBAT

FOEPYT

RENIATNOC

THGIEWTENTHGIEWERATSSORG

THGIEW

EDISTUO

RETEMAID

HTGNEL

SREDNILYC bl001

bl051

bl511-36

bl041-58

bl512-361

bl092-532

"¾01-"¼8

"¾01-"¼01

"11'4-"½3'3

"8'4-"5'4

NOT

RENIATNOC

bl0002bl0561-0031bl0563-033"6'2"½01'6-"¾7'6

TINUELGNIS

SRACKNAT

snot61

snot03

snot55

snot58

snot09

-

-

-

-

-

-

-

-

-

-

"0'21-"5'01

"7'31-"½4'21

"1'51-"3'41

"1'51-"11'41

"1'51-"11'41

"3'33-"2'23

"½11'53-"01'33

"0'34-"9'92

"0'05-"7'34

"2'74-"8'54

.cnI,etutitsnIenirolhCehtybdehsilbup,noitidEhtfiF,launaMenirolhCmorfatadlanoisnemiD

aivytpmerollufdeppihsebyamezisbl051robl001ehtrehtiE.elbaliavaylidaertsomyllarenegsirednilycbl051ehT)1(

.sdaolracrokcurtllufnirostolllamsniliarrokcurt

ehtetanimileotredronidedeensaracehtmorfyltceriddedaolnuyllarenegsisraCknaTtinUelgniSmorfenirolhC)2(

owT.ylnosgnidisetavirpotdengisnoceradnadoirepsihtgnirudremusnocehtotdesaelerasraC.sknategarotsfoytissecen

nwod-tuhstuohtiwnoitareposuounitnoctimrepotdnasracfognildnahehtetatilicafotdednemmocereraskcartlellarap

.dehctiwsgnieberasracelihwsdoirep

Loading...

Loading...