IM 25.000AA UA (B/6-00)

CHLORINE HANDLING MANUAL

PAGE 8

WARNING: NEVER LIFT CYLINDERS BY THE

VALVE PROTECTING HOOD. THE HOOD MAY

SEPARATE FROM THE CYLINDER, CAUSING THE

CYLINDER TO FALL.

Never lift cylinders by sling or magnetic devices. If lifting is

necessary, use a specially designed cradle. Contact your

chlorine supplier for recommendations or information.

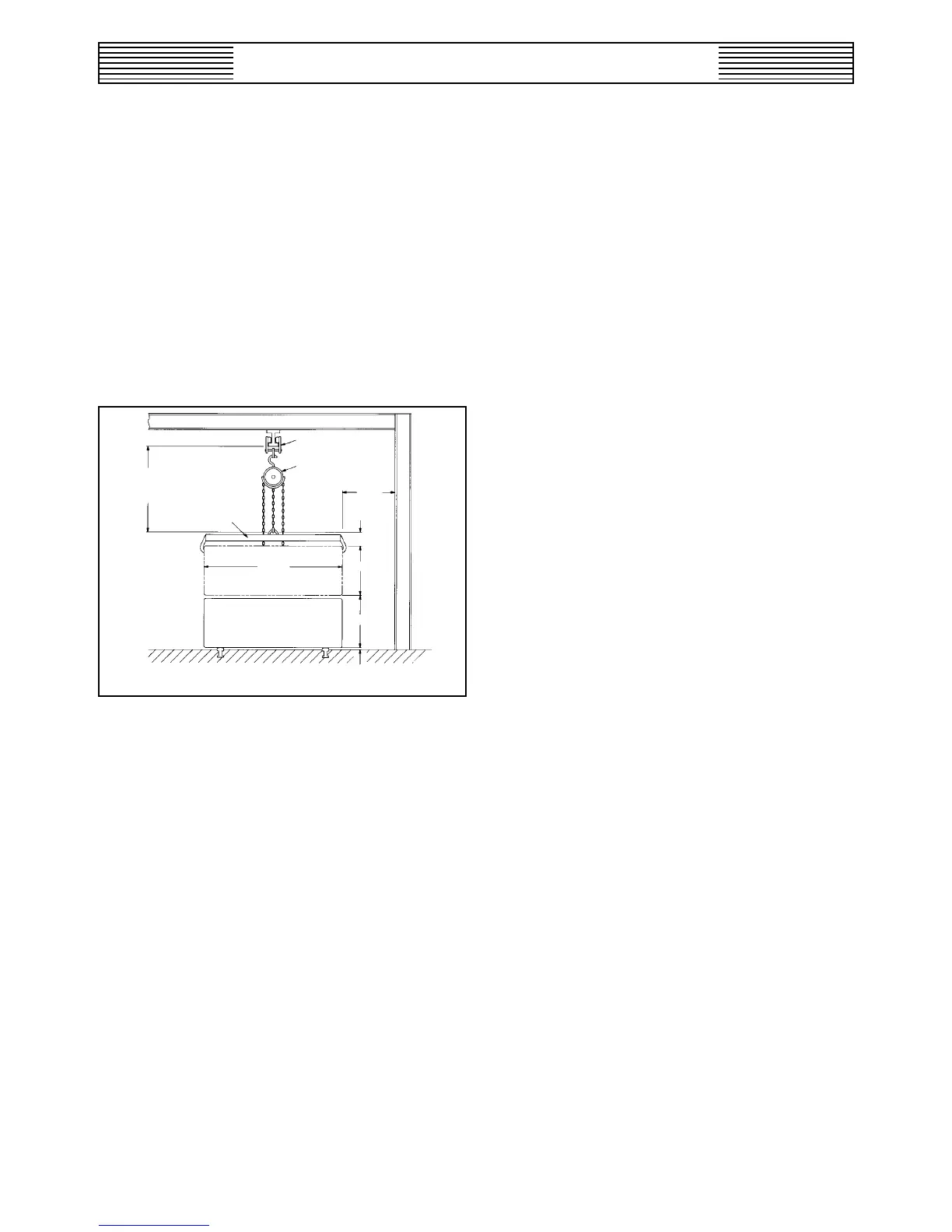

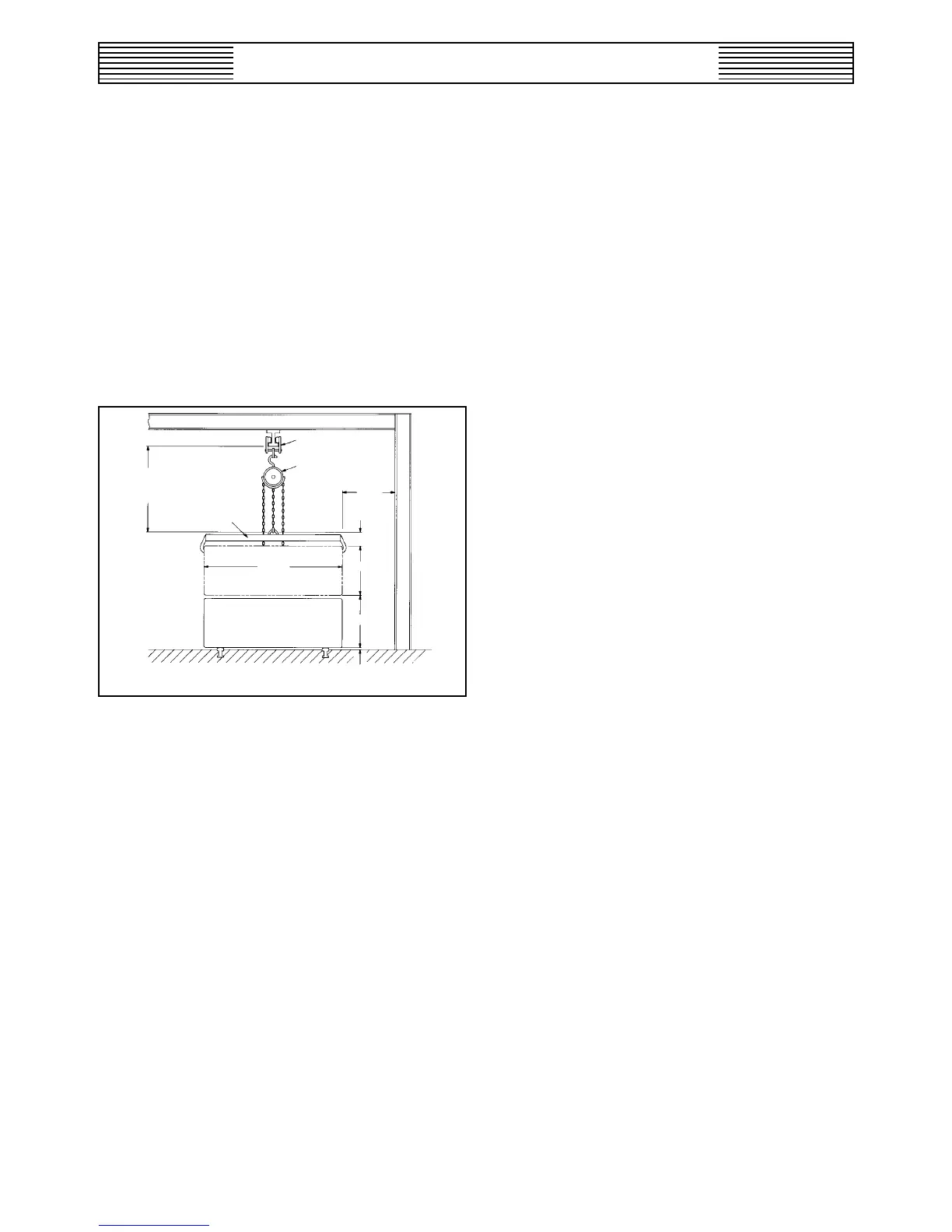

When moving ton containers, due consideration must be

given to the fact that the liquid in the container represents a

live load in addition to the dead load of the container and the

liquid. The most accepted way of moving ton containers is by

overhead conveyor and lifting beam (see Figure 11).

Figure 11 – Ton Container Handling

THIS DIMENSION

DETERMINED BY

REQUIREMENTS OF

LIFTING DEVICE

OVERHEAD MONORAIL

HOIST

(4000 LB. MIN.)

2’-7”

CLEARANCE

LIFTING BAR

13”

2’-6”

2’-8”

1/2”±

6’-10”

Rails or roller conveyors have also been used. Fork lift trucks,

in addition to having adequate capacity, must have the con-

tainers restrained and be sufficiently stable to prevent tip-

ping.

3.7 USING CONTAINERS

If containers have been stored in an area other than that in

which they will be used, they should be allowed to stabilize

at the new temperature before being used. Containers should

always be used in the order in which they are received to

avoid unnecessarily long storage and possible difficulty with

valves that have not been opened or closed for too long a

period.

WARNING: CYLINDERS ARE NORMALLY USED IN

AN UPRIGHT POSITION FOR GAS WITHDRAWAL.

TO AVOID SEVERE PERSONAL INJURY OR EQUIP-

MENT DAMAGE, SUPPLY CYLINDERS MUST BE

SECURED IN SUCH A MANNER (E.G., CHAIN) AS

TO PREVENT THEIR BEING KNOCKED OVER. TON

CONTAINERS MUST BE USED IN A HORIZONTAL

POSITION WITH THE TWO VALVES IN A VERTI-

CAL LINE. TON CONTAINERS MUST BE SECURED

IN SUCH A MANNER (E.G., CHOCKS) TO PREVENT

THEIR ROLLING OUT OF PLACE.

When withdrawing gas from a ton container, connection is

made to the upper valve (see Figure 6). Liquid withdrawal is

accomplished by connecting to the lower valve.

It is recommended that special 3/8-inch square box wrenches,

rather than adjustable wrenches, be used for opening cylin-

der and ton container valves. Length of the wrench should

not exceed eight inches. It is good practice to leave the wrench

in place so the valve can be closed quickly in case of an

emergency. Maximum discharge can be accomplished with

one full turn of the valve. Excessive force must not be used

in opening valves. Never strike the wrench with anything

other than the heel of the hand. Loosening the packing nut

a maximum of 1/2 turn is acceptable, provided the packing

nut is tightened after the valve is operated. Contact your

chlorine supplier if these procedures do not permit operation

of the valve.

Angle valves on tank cars must be opened fully to aid the

operation of the excess flow valve.

Always test for leaks before putting new containers in ser-

vice. The system can be pressurized by opening the container

valve and then closing it. The valve can be opened again after

it is determined that there are no leaks.

WARNING: ALWAYS WEAR PROTECTIVE CLOTH-

ING WREN CHECKING FOR LEAKS. REFER TO

“PERSONNEL SAFETY” FOR INFORMATION ON

HEALTH HAZARDS AND SAFETY PRECAUTIONS.

It is not unusual during humid conditions for condensation

to collect on the outside of the container. A buildup of frost

on the container indicates that withdrawal rates are too high

to permit the surrounding air to supply the heat necessary to

evaporate the liquid chlorine. Increasing the circulation of

room temperature air past the container may correct the

condition. Do not apply direct heat to the container in any

way. It may be necessary to shut off the container valve and

permit it to warm up again before putting it back in service.

After emptying the container, the valve must be closed before

disconnecting to prevent the entry of moisture. After discon-

necting, the valve cap and the valve protecting cap or hood

must be replaced before the container is moved. Empty con-

tainers should be segregated from full containers and should

be tagged.

Loading...

Loading...