IM 25.000AA UA (B/6-00)

CHLORINE HANDLING MANUAL

PAGE 10

encountered. Do not run these gas lines along exterior walls

that may be cold in winter months. Do not run pressure gas

lines under windows from which cold air descends in winter

months.

If the source of gas is one or more ton containers connected

to a manifold, install a drip leg of 1.0-inch schedule 80

seamless steel pipe approximately 18 inches long in a tee in

the manifold with the lower end capped. Locate the drip leg

immediately downstream of the last container connection to

intercept the liquid that comes from the ton containers’ gas

eduction tubes when initially opened.

Gas may be withdrawn from two or more containers simul-

taneously provided all containers are at the same tempera-

ture. Refer to Paragraph 3.1.

The installation of chlorine gas strainers in pipe lines up-

stream from pressure reducing valves or vacuum regulators

is a common practice. These strainers can also serve as traps

for a small amount of liquid chlorine. Figure 12 illustrates a

typical strainer.

Figure 12 – Chlorine Gas Strainer

HOUSING

GASKET

SCREEN

AND COVER

BOLT

4.3 LIQUID PIPING INSTALLATION REQUIRE-

MENTS

It is important to avoid conditions that will encourage vapor-

ization. Thus it is important to keep liquid chlorine lines as

cool as, or cooler than, the containers themselves by elimi-

nating restrictive fittings and always operating with fully

opened line valves. Avoid running liquid chlorine lines

through overheated areas where gasification is likely.

Valves in liquid chlorine lines should be kept to a minimum.

It is particularly important to avoid situations where it is easy

to close two valves in a line thus trapping liquid that, upon

an increase in temperature, will expand and develop higher

than acceptable pressures.

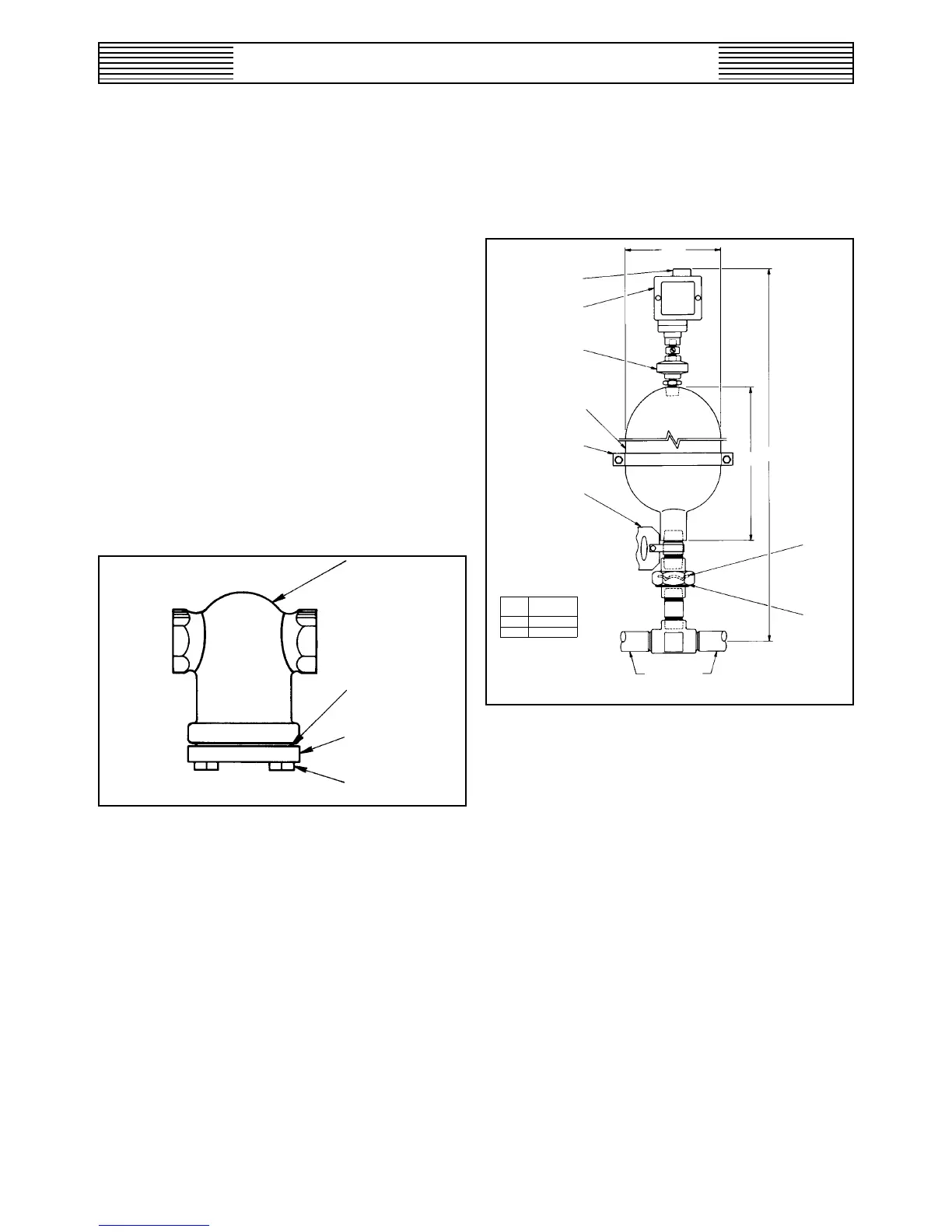

A liquid line pressure relief system (which includes a rupture

disc and an expansion chamber) is required where liquid

may be trapped in the line or where it is necessary to run lines

a considerable distance. The relief system is detailed in Fig-

ure 13.

Figure 13 – Liquid Line Pressure Relief System

6-5/8”

1/2” FEMALE NPT FOR

115 V ELECTRICAL

CONNECTION

PRESSURE

SWITCH

DIAPHRAGM SEAL

UNIT

EXPANSION

CHAMBER

SUPPORT BRACKET

WARNING LABEL

LENGTH OF LIQUID LINE

PROTECTED PER EXPANSION

CHAMBER SYSTEM

1” CHLORINE

LINE

UNION

HEAD

RUPTURE

DISC

46-1/4”

30”

EPIP

EZISENIROLHC

"1'573

"4/3'526

The expansion chamber provides an area for expansion in

the event that valves at both ends of the line are closed.

Relief system placement must be based not only on length

of line but also placement of valves.

4.4 PRESSURE RELIEF AND VENT PIPING RE-

QUIREMENTS

All pressure relief vent line systems must be treated as though

they contain chlorine. Use the same materials for pressure

relief vent lines as used for chlorine gas piping, unless the

vent line is a combination pressure relief/vacuum relief line

in which case the material must be suitable for moist chlorine

gas (PVC or polyethylene tubing).

Vent lines must be run in such a way that moisture collecting

traps are avoided. A continuous gradient is preferred. The

end of all vent lines must be turned down and screened.

Manifolding of vent lines is an acceptable practice provided

only like vents are manifolded (i.e., evaporator water vapor

Loading...

Loading...