CHLORINE HANDLING MANUAL

IM 25.000AA UA (B/6-00) PAGE 11

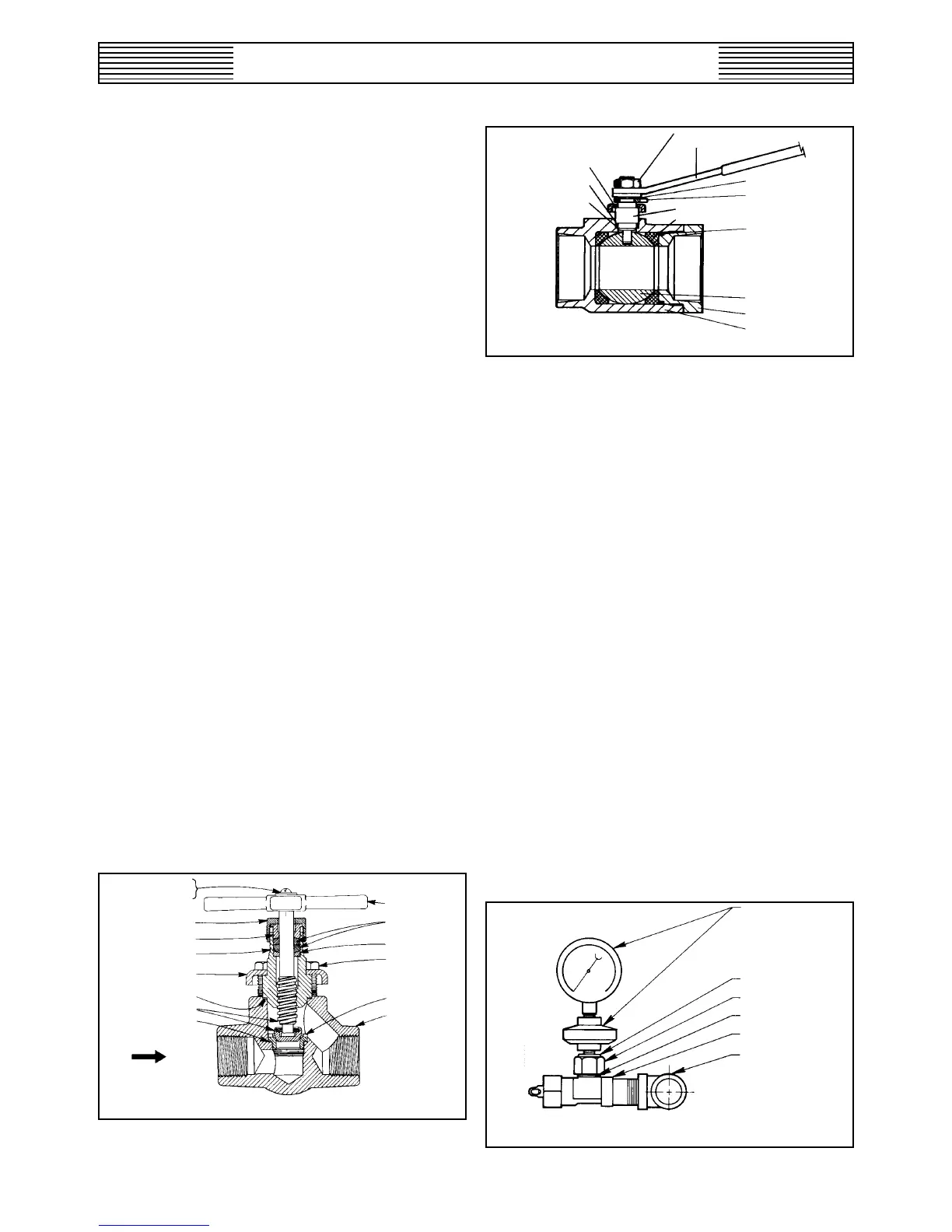

Figure 15 – Gas and Liquid Ball Valve

vents must be separate from gas pressure reducing valve

pressure vents, etc.). The interior cross sectioned area of a

common vent or pressure relief line should be approximately

equal to the sum of the cross sectional areas of the individual

vent lines.

WARNING: THE VENT LINE AND RELIEF LINE

MUST TERMINATE IN AN AREA GAS FUMES CAN-

NOT CAUSE INJURY TO PERSONNEL OR DAMAGE.

DO NOT TERMINATE THE VENT LINE AND RE-

LIEF LINE AT A LOCATION ROUTINELY USED BY

PERSONNEL, SUCH AS WORK AREAS OR PATH-

WAYS NOR NEAR ANY WINDOWS OR VENTILA-

TION SYSTEM INTAKES. IF AN AREA MEETING

THESE REQUIREMENTS IS NOT AVAILABLE,

REFER TO THE CHLORINE INSTITUTE’S CHLO-

RINE MANUAL AND PAMPHLET NO. 9 FOR AL-

TERNATE METHOD OF RELIEF DISPOSAL.

4.5 VALVES

Yoke type auxiliary cylinder, yoke type auxiliary ton con-

tainer, and header valves are described adequately in the

chlorinator or vacuum regulator instruction book.

Line valves are used to isolate alternate sources of supply

(manifolded banks of ton containers or tank cars), individual

evaporators or pressure type chlorinators. Sufficient line

valves should be provided for flexibility of system operation

consistent with the recommended practice of eliminating

redundant or unnecessary valves.

Valves are usually of approximately globe pattern as shown

in Figure 14 or ball type as shown in Figure 15.

Care should be taken that only valves designed by the manu-

facturer specifically for chlorine service are used. Ball valves

must include a provision for venting the cavity in the closed

position to the upstream side.

Figure 14 – 3/4- and 1-Inch Line Valves

MACH. SCREW

WASHER

PACKING NUT

PACKING GUARD

PACKING BOX

GAP

LEAD GASKET

STEM UNIT

LEAD GASKET

INLET

HANDLE

PACKING

PACKING RING

CAP SCREW (4)

SEAT

VALVE BODY

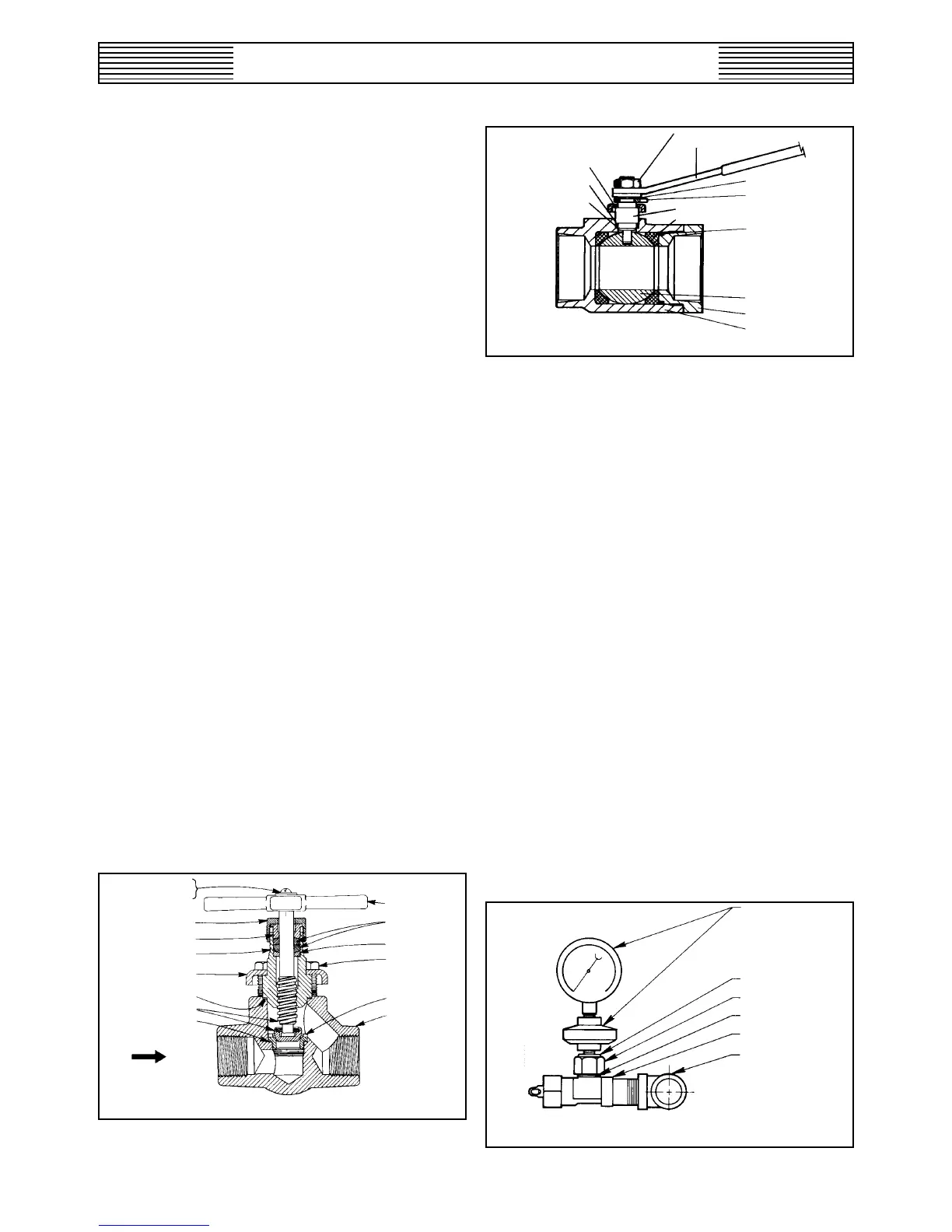

4.6 PRESSURE GAUGES AND SWITCHES

Whenever pressure gauges and switches are used in chlorine

liquid or gas lines, they must be of the type protected by a

flanged diaphragm seal specifically designed for chlorine ser-

vice to prevent the entry of chlorine into the gauge or switch

mechanism. The fill material must be suitable for chlorine

service. The connection between the seal and the gauge or

switch must not be broken. If the connection is inadvertently

broken, the complete assembly must be discarded and replaced,

unless it can be returned to the manufacturer for repair.

Frequently, valves are installed between chlorine lines and

the gauge or switch diaphragm seal to permit removal with-

out taking the line out of service. A means of relieving the

pressure in the isolated piping, gauge, or switch is strongly

recommended.

WARNING: RELEASING EVEN A SMALL AMOUNT

OF LIQUID CHLORINE IS DANGEROUS AND RE-

QUIRES EXTREME CAUTION TO AVOID SEVERE

PERSONAL INJURY. ALWAYS USE PROTECTIVE

EQUIPMENT WHEN RELIEVING PRESSURE, EVEN

IN ISOLATED CHLORINE GAS PIPING.

Since small size line valves for chlorine are not readily avail-

able, many times a header valve is used as shown in Figure 16.

Figure 16 – Chlorine Pressure Gauge or

Switch Mounted on Header Valve

PRESSURE GAUGE

(OR SWITCH) AND

DIAPHRAGM

UNION ADAPTER

UNION NUT

LEAD GASKET

HEADER VALVE

3/4” CONNECTION

IN GAS LINE

RETAINING RING

INDICATOR STOP

BODY SEAL

BALL

BODY CAP

BODY

STEM

SEAT

HANDLE

STEM NUT

BONNET PLATE

STEM BEARING

STEM SEAL

Loading...

Loading...