IM 25.055AC UA (C/6-01)

AUTOMATIC CHLORINATOR - 3000LB/24HR

38

4.11.2 Cleaning

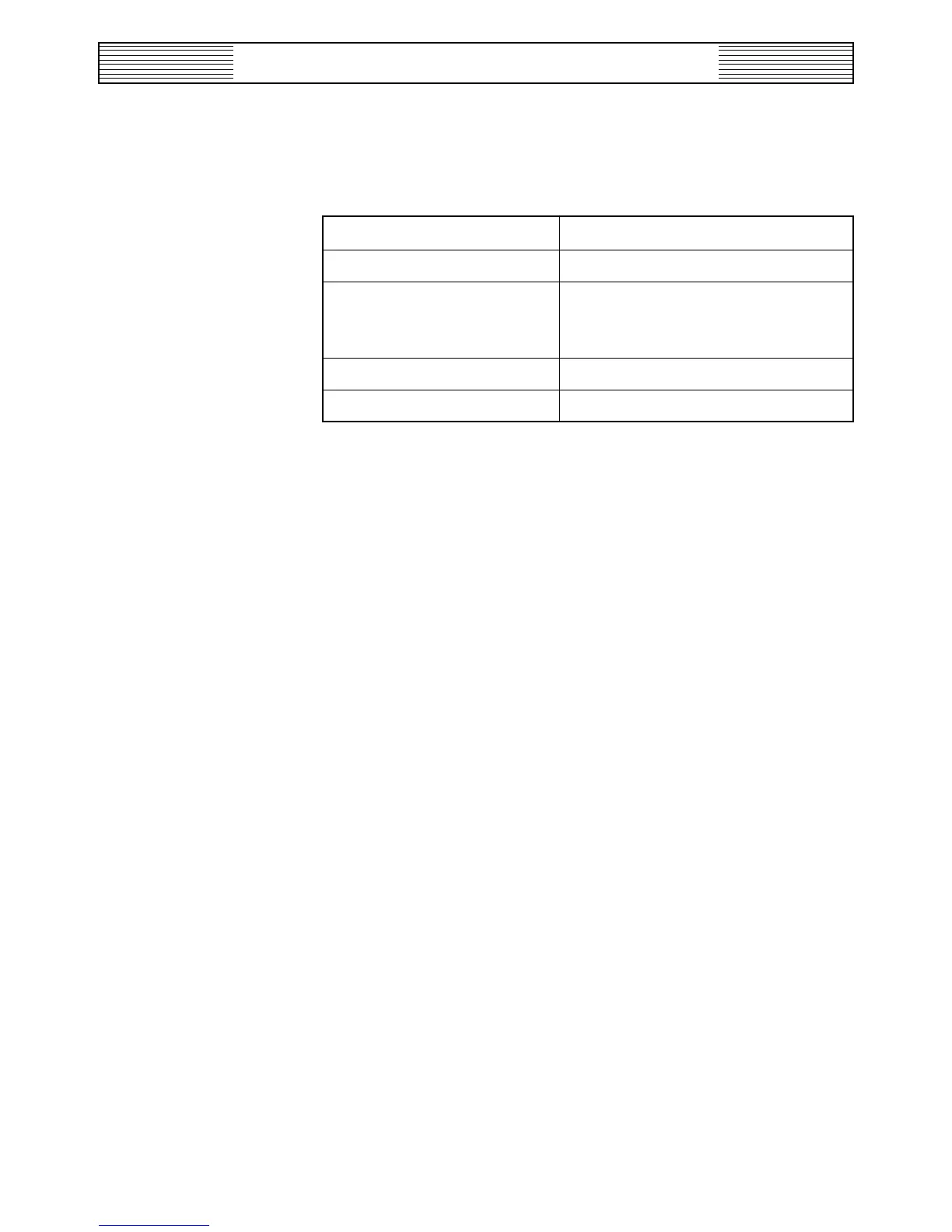

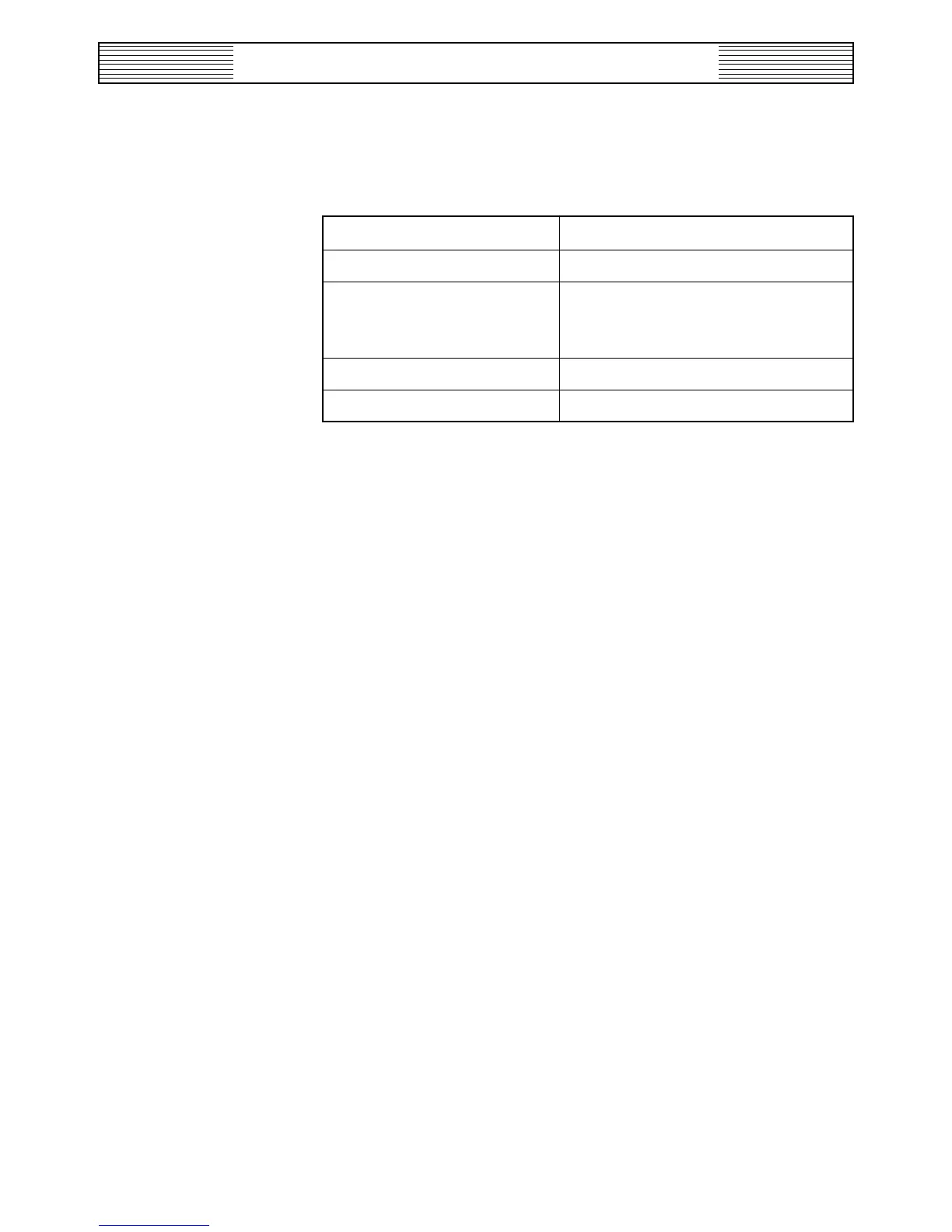

At intervals as tabulated below:

METIECNANETNIAMMROFREPOTNEHW

rotalugeRmuucaV.koobnoitcurtsnietarapesotrefeR

retematoRehtedisnineeserastisopednehW

enoniskcitstaolfehtroebutssalg

.ecalp

gulPhctoN-V.retematorsaemitemastA

yawliaT&taorhTrotcejnI.shtnomxisyrevE

NOTE: The actual frequency of cleaning will depend on calendar

time, the feed rate and amount of gas fed, the care exercised in cylin-

der changing, the source of gas, and the quality of the operating

water. The above maintenance schedule provides recommended clean-

ing intervals; however, your own operating experience is the best

guide to preventive maintenance and may result in significant varia-

tions from the recommended schedule.

4.11.3 Cleaning Rotameter

If a milky-white, powdery-white, green-slimy, or brown-oily deposit is

visible inside the rotameter tube, or if the float has particles clinging to it

or tends to stick to the tube wall at lower feeds, it is time to clean the

rotameter. Proceed carefully to avoid dropping the glass tube or losing the

float down a floor drain or grating. To facilitate handling the float, have a

clean cup, such as a coffee cup or a small beaker, and a pair of tweezers

on hand before starting. Proceed as follows:

a. Turn the knob on the vacuum regulator(s) to OFF. After the supply

vacuum gauge reads 100 inches of water and the rotameter float rests

on the bottom stop, turn off the injector operating water.

b. Remove rotameter. Take care not to lose the end stops, the float, or

any of the O-rings. See Dwg. 25.055.151.010.

c. Place the end stops and float into the cup mentioned above.

d. Many gas contaminants are soluble in water. Hold the tube end under

running warm (110-125°F) water so that the water enters the tube at

one end and exits at the other to flush out deposits. Alternately, soak

the tube in a container of warm water for about 30 seconds. Then

Loading...

Loading...